Roller type press cutting machine

A press-cutting machine and roller-type technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of high power consumption, poor overturning effect, large power consumption, etc., and achieve reduced power consumption and light structure. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

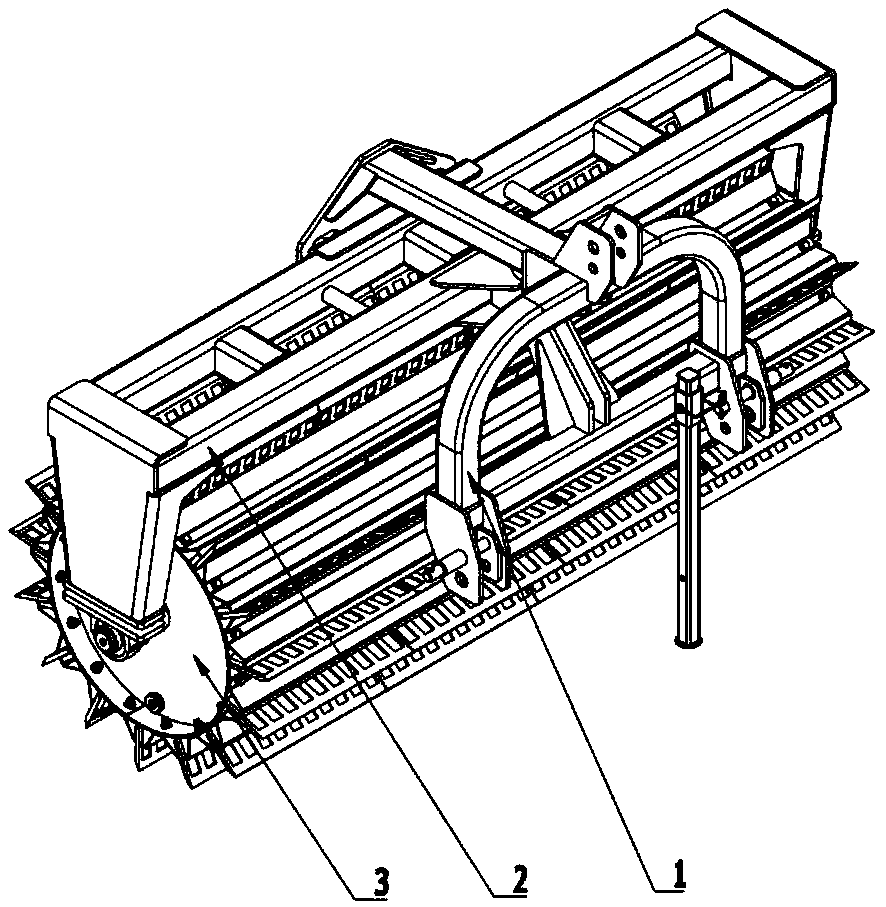

[0028] The roller press cutter of this embodiment takes into account the overturning operation of green manure in standard farmland and orchards, and its basic structure is as follows: figure 1 As shown, it includes a suspension assembly 1 for connecting with the traction device, a support assembly 2 connected with the suspension assembly 1 , and a roller assembly 3 supported under the support assembly 2 .

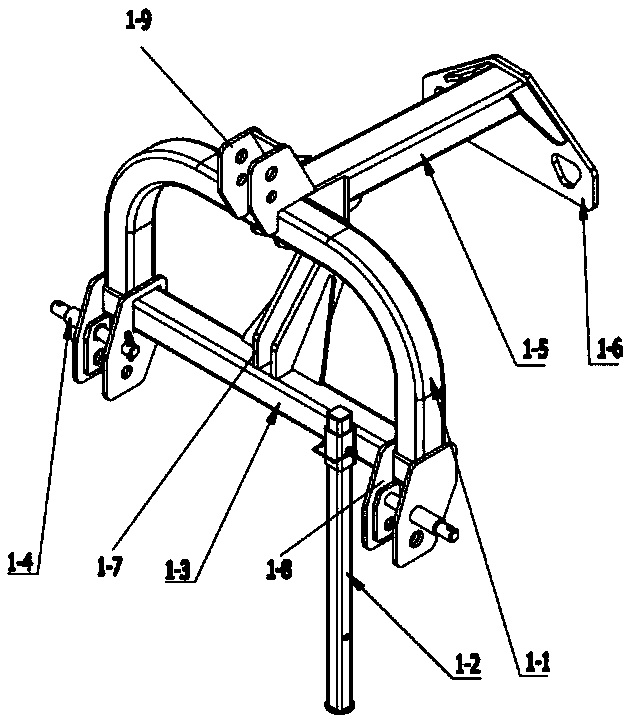

[0029] The structure of the suspension assembly 1 is as figure 2 As shown, it contains a door-shaped frame 1-1, the upper center of the door-shaped frame 1-1 is fixed with a longitudinal beam 1-5 extending forward, and the front end of the longitudinal beam 1-5 is fixedly connected with the vertical jack plate 1-5. 6. A transverse beam 1-3 is fixedly connected between the two lower ends of the portal beam 1-5, and the center of the transverse beam 1-3 extends out a supporting frame 1-7 for installing the supporting component 2. A connection plate 1-9 is provided above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com