Spliced and inserted type six-degree-of-freedom joint type industrial robot and control system

A technology of industrial robots and control systems, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of high cost and heavy weight of the machine body, and achieve the effects of weight reduction, cost reduction, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to deepen the understanding of the present invention, the principles and features of the present invention will be further described below in conjunction with the examples and accompanying drawings. The examples are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

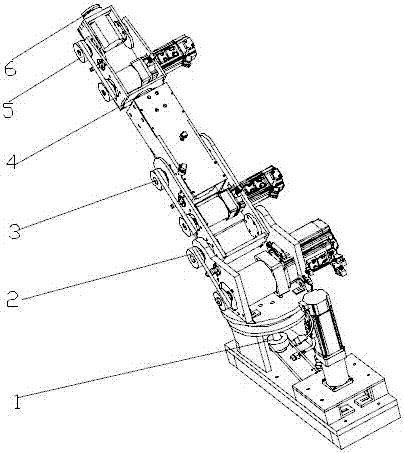

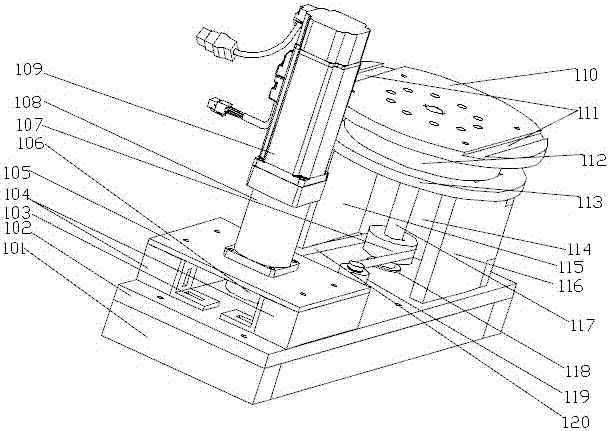

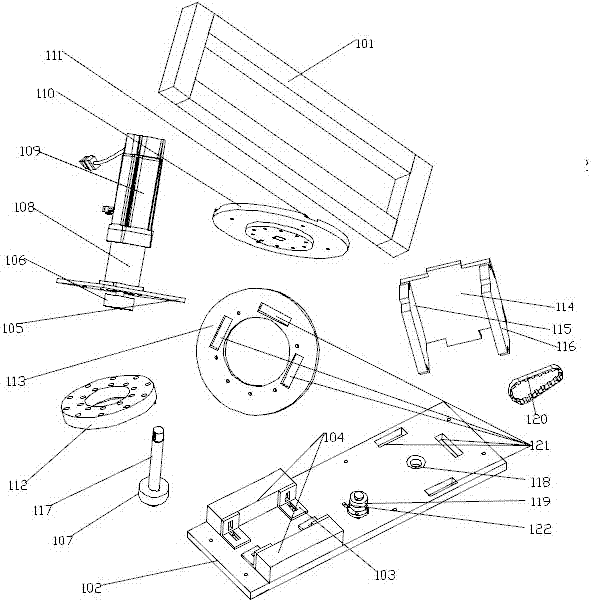

[0033] see figure 1 , the joint-type six-degree-of-freedom articulated industrial robot of the present invention includes a first revolving joint 1, a second revolving joint 2, a third revolving joint 3, a fourth revolving joint 4, a fifth revolving joint 5, and a sixth revolving joint 6.6 The drive of the two joints comes from the first servo motor 109 installed with the first reducer 108, the second servo motor 203 of the second reducer 204, the third servo motor 305 of the third reducer 306, and the fourth reducer 408. The fourth servo motor 407 of the fifth reducer 506, the fifth servo motor 505, and the stepper motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com