Harvester

A harvester and frame technology, applied in the field of harvesters, can solve the problems of large weight and volume, poor harvesting adaptability, difficult field transfer, etc., and achieve the effect of solving the weight of the machine and improving the work adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described

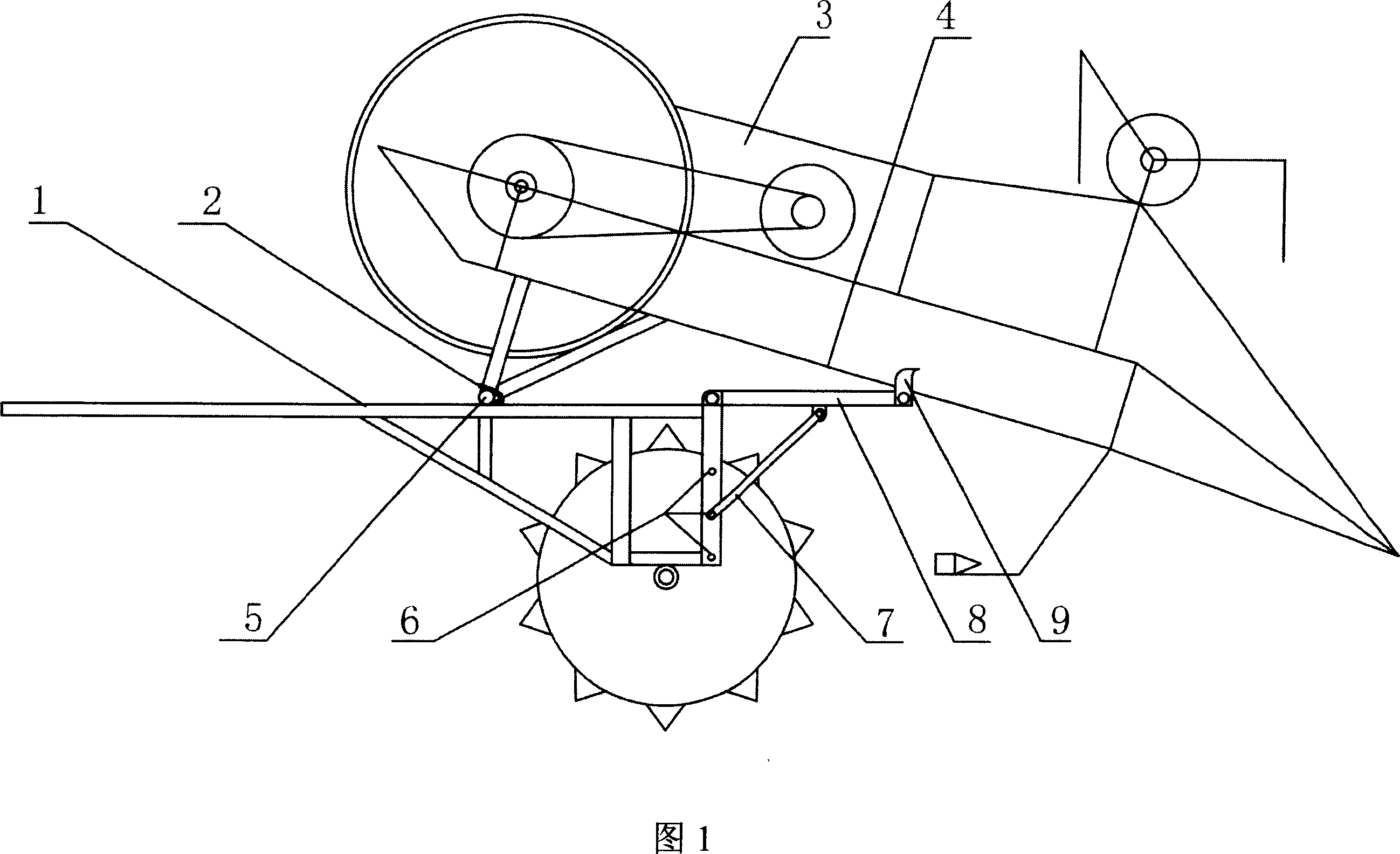

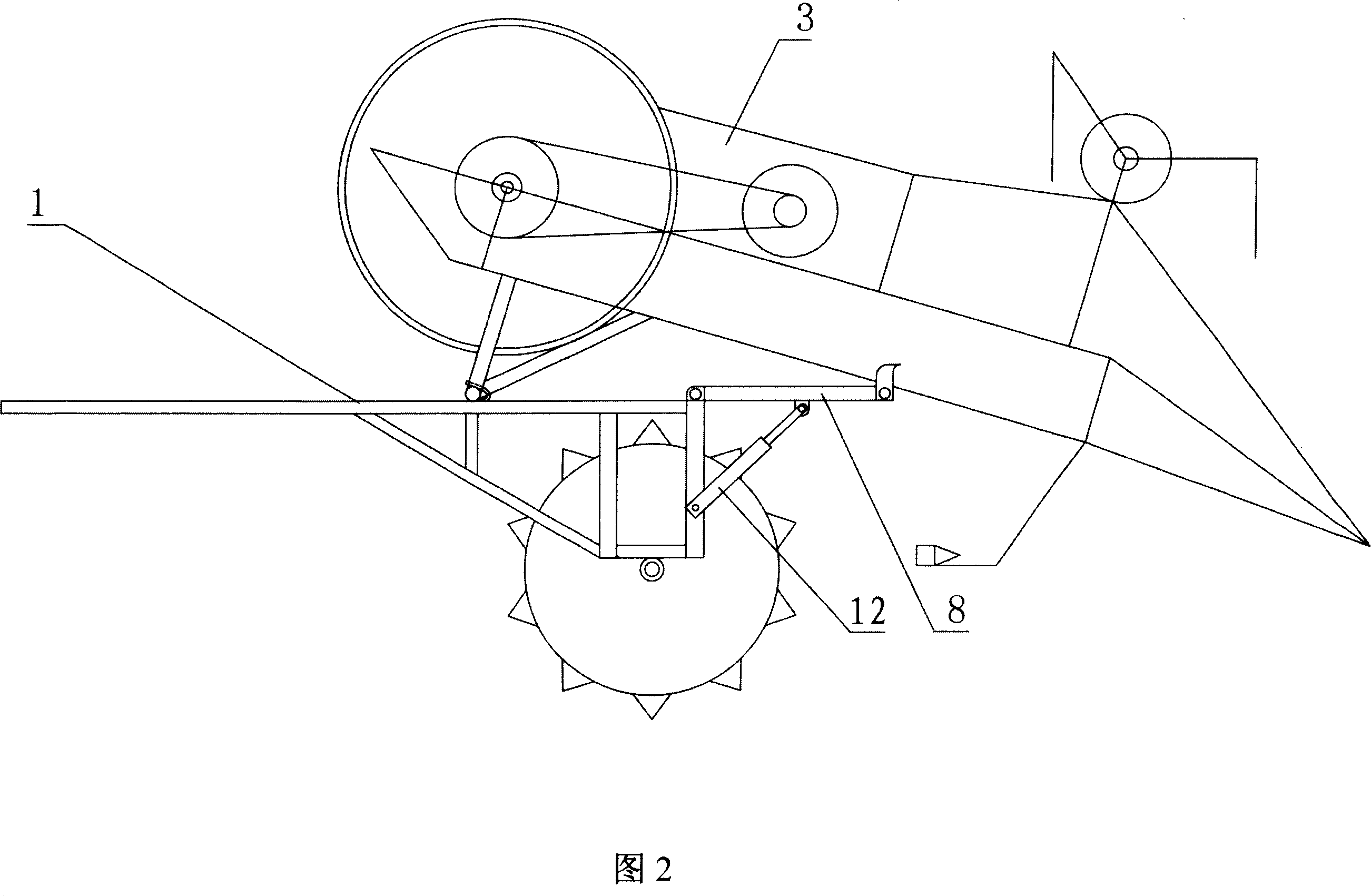

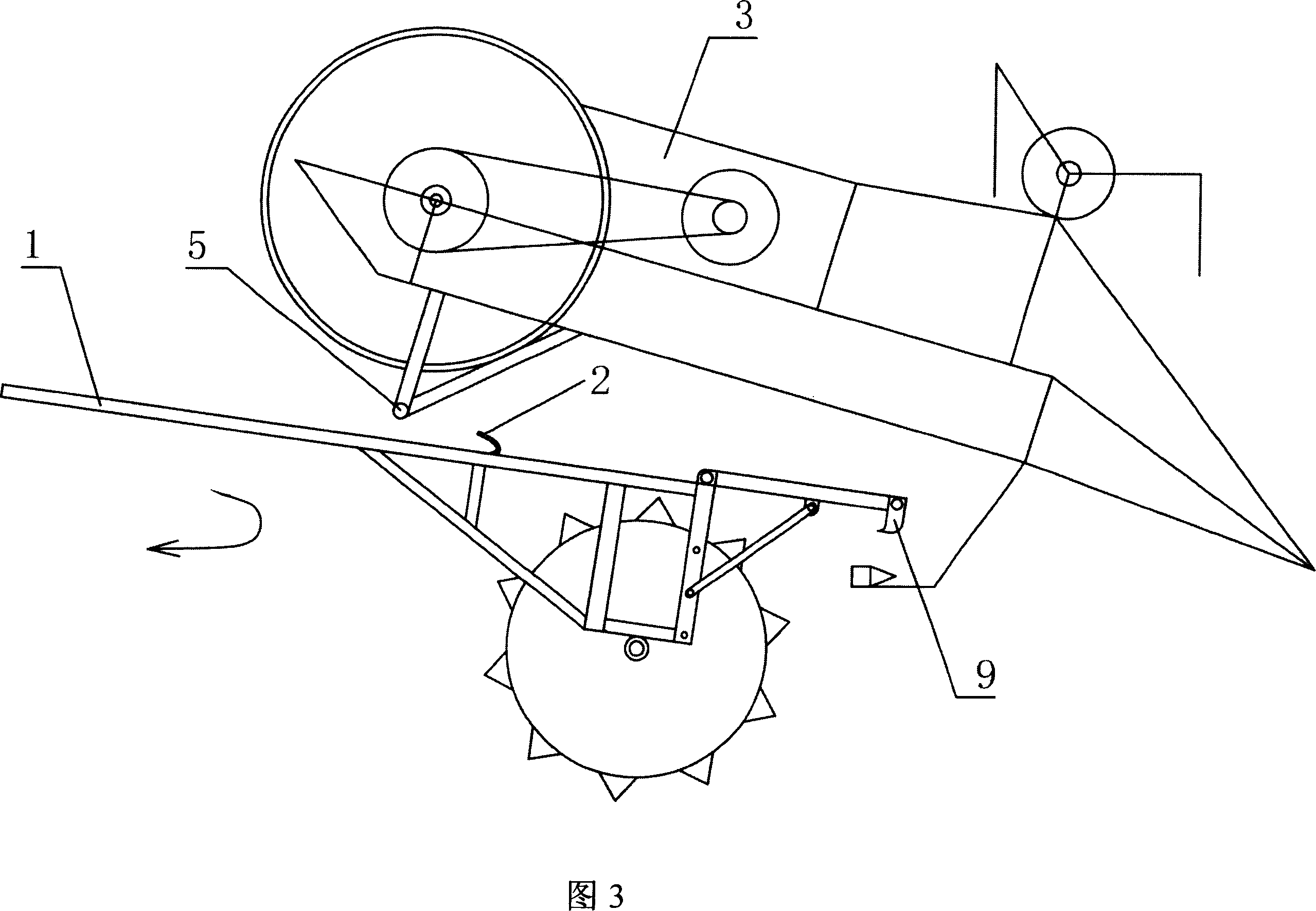

[0018] Among Fig. 1, the harvesting operation part 3 is installed on the frame 1 of the harvester, the positioning hook 2 is installed in the middle of the frame 1, and is flexibly connected with the positioning rod 5 positioned at the rear part of the harvesting operation part 3; the middle part of the harvesting operation part 3 leans against the On the ejector rod 8; the ejector rod 8 is movably installed on the head of the frame 1, the middle part of the ejector rod 8 is connected with the support rod 7, and the other end of the support rod 7 is connected with the positioning hole 6 on the frame 1, and the support rod 7 is connected with the positioning hole 6 There are three positioning holes on the frame. According to the height of the harvested crops, different positioning holes 6 are selected to connect with the poles 7. When the harvested crops are relatively high, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com