Bag feeding mechanism for packaging bags

A technology of packaging bags and transmission mechanisms, applied in packaging and other directions, can solve the problems of bag failure and affect the efficiency of the packaging process, and achieve the effect of ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

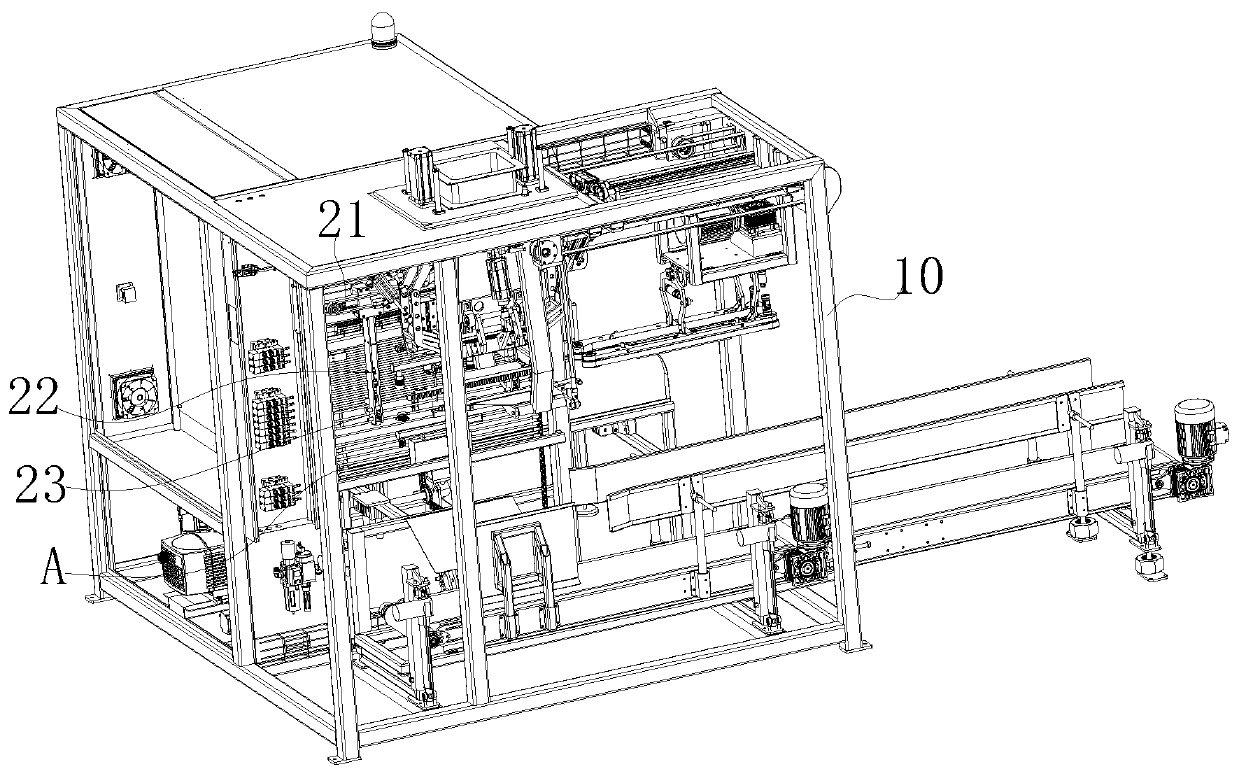

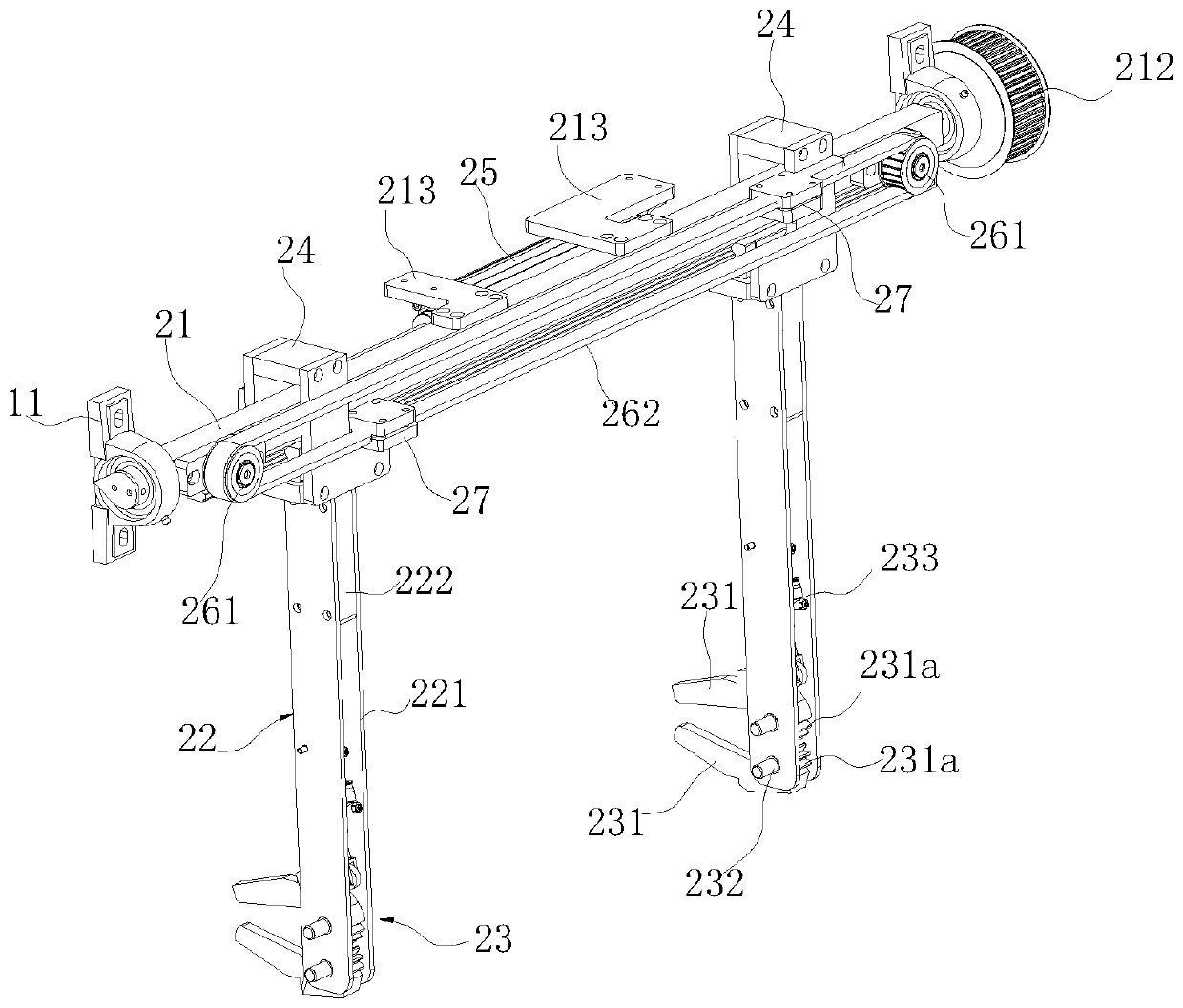

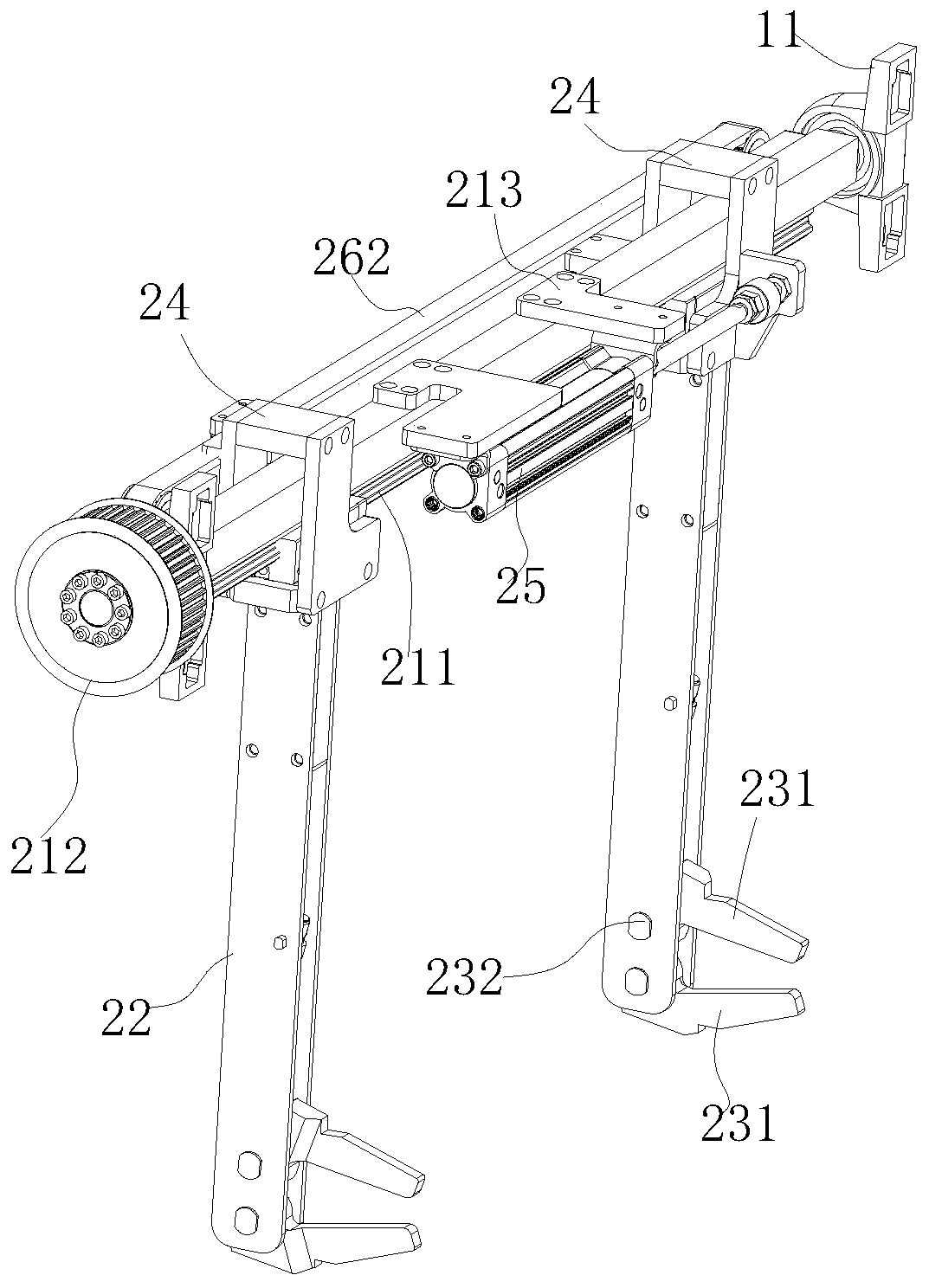

[0009] like Figure 1-Figure 3 As shown, a bag-loading mechanism for a packaging bag is provided with a rotating shaft 21 on the frame 10 above the chain plate transmission mechanism A. The shaft body of 21 is provided with two support arms 22 whose length direction is perpendicular to the length direction of the rotating shaft 21. The upper end of the supporting arm 22 forms a sliding fit with the rotating shaft 21 in the axial direction, and the lower end protrudes toward the direction A of the chain plate transmission mechanism. There is a retractable support plate 23. The mouth of the packaging bag placed on the chain plate transmission mechanism A faces the bag opening mechanism, and the bag opening mechanism on the frame 10 (generally two sets of suction cups, respectively suck the upper and lower bags of the mouth of the bag, and open the mouth of the bag) After opening, the two support arms 22 move in translation on the rotating shaft 21, and the height of the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com