A kind of transparent heat-resistant polylactic acid composition and its preparation method

A technology of polylactic acid and composition, applied in the field of transparent heat-resistant polylactic acid composition and its preparation, can solve the problems of precipitation and high addition of plasticizer, and achieve the effects of high transparency, fast crystallization rate and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

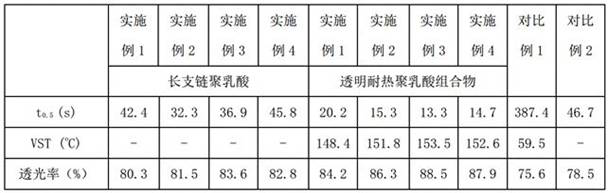

Examples

Embodiment 1

[0033] In this embodiment, the preparation method of this transparent heat-resistant polylactic acid composition includes the following steps in sequence:

[0034] (1) Preparation of long-chain branched polylactic acid:

[0035] (1-1) Prepare the following raw materials by weight: the second part of polylactic acid 97.9%, di-(tetradecyl) peroxydicarbonate 1.2%, antioxidant 168 0.9%;

[0036] (1-2) Dry the second part of polylactic acid at 110°C for 50 minutes, and cool to 25°C;

[0037] (1-3) adding di-(tetradecyl) peroxydicarbonate and antioxidant 168 to the second part of polylactic acid, and mixing evenly to obtain the first mixed material;

[0038] (1-4) Melt and extrude the first mixed material obtained in step (3) through the first twin-screw extruder, and carry out stranding, air cooling, and cutting of the material extruded by the first twin-screw extruder Particles to obtain granular long-chain branched polylactic acid;

[0039] (2) Preparation of transparent heat-...

Embodiment 2

[0048] In this embodiment, the preparation method of this transparent heat-resistant polylactic acid composition includes the following steps in sequence:

[0049] (1) Preparation of long-chain branched polylactic acid:

[0050](1-1) Prepare the following raw materials by weight: the second part of polylactic acid 98.24%, di-(tetradecyl) peroxydicarbonate 1.00%, antioxidant 168 0.76%;

[0051] (1-2) Dry the second part of polylactic acid at 100°C for 30 minutes, and cool to 20°C;

[0052] (1-3) adding di-(tetradecyl) peroxydicarbonate and antioxidant 168 to the second part of polylactic acid, and mixing evenly to obtain the first mixed material;

[0053] (1-4) Melt and extrude the first mixed material obtained in step (3) through the first twin-screw extruder, and carry out stranding, air cooling, and cutting of the material extruded by the first twin-screw extruder Particles to obtain granular long-chain branched polylactic acid;

[0054] (2) Preparation of transparent hea...

Embodiment 3

[0063] In this embodiment, the preparation method of this transparent heat-resistant polylactic acid composition includes the following steps in sequence:

[0064] (1) Preparation of long-chain branched polylactic acid:

[0065] (1-1) Prepare the following raw materials by weight: the second part of polylactic acid 97.90%, di-(tetradecyl) peroxydicarbonate 1.20%, antioxidant 168 0.90%;

[0066] (1-2) Dry the second part of polylactic acid at 120°C for 70 minutes, and cool to 30°C;

[0067] (1-3) adding di-(tetradecyl) peroxydicarbonate and antioxidant 168 to the second part of polylactic acid, and mixing evenly to obtain the first mixed material;

[0068] (1-4) Melt and extrude the first mixed material obtained in step (3) through the first twin-screw extruder, and carry out stranding, air cooling, and cutting of the material extruded by the first twin-screw extruder Particles to obtain granular long-chain branched polylactic acid;

[0069] (2) Preparation of transparent he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com