Rail for vehicle seat and vehicle seat comprising such rail

A technology for vehicle seats and rails, which is applied in vehicle seats, special positions of vehicles, vehicle components, etc., and can solve problems such as noise, heavy weight, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the various drawings, the same reference numerals designate the same or similar elements.

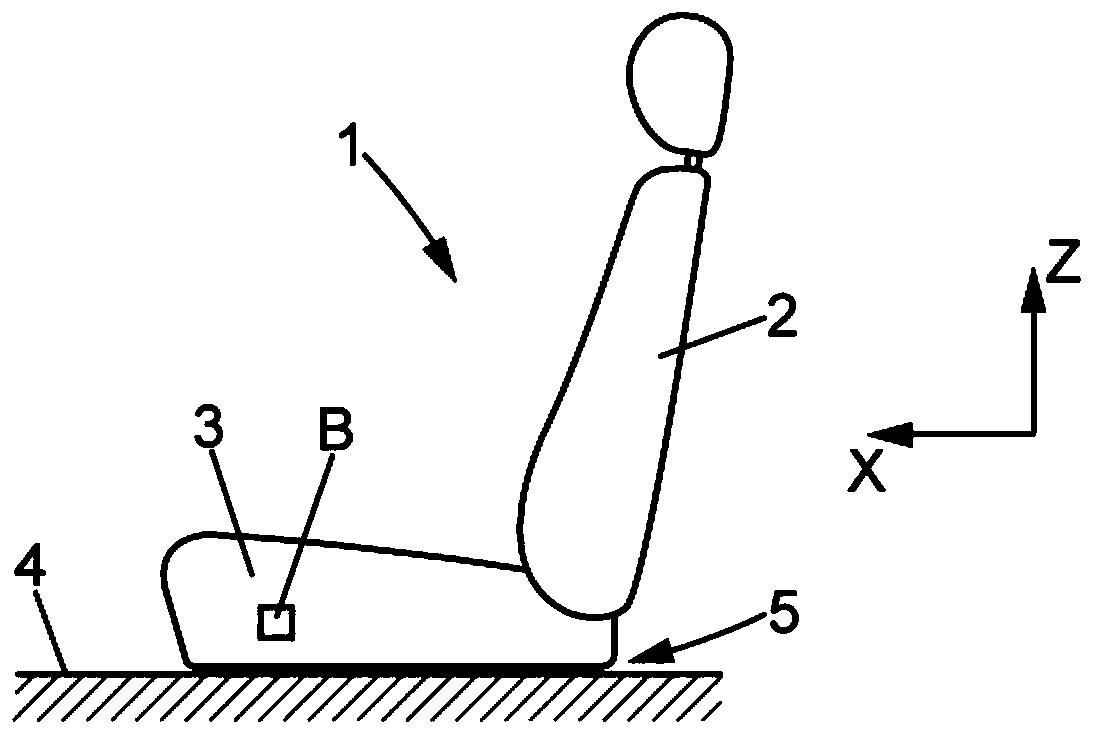

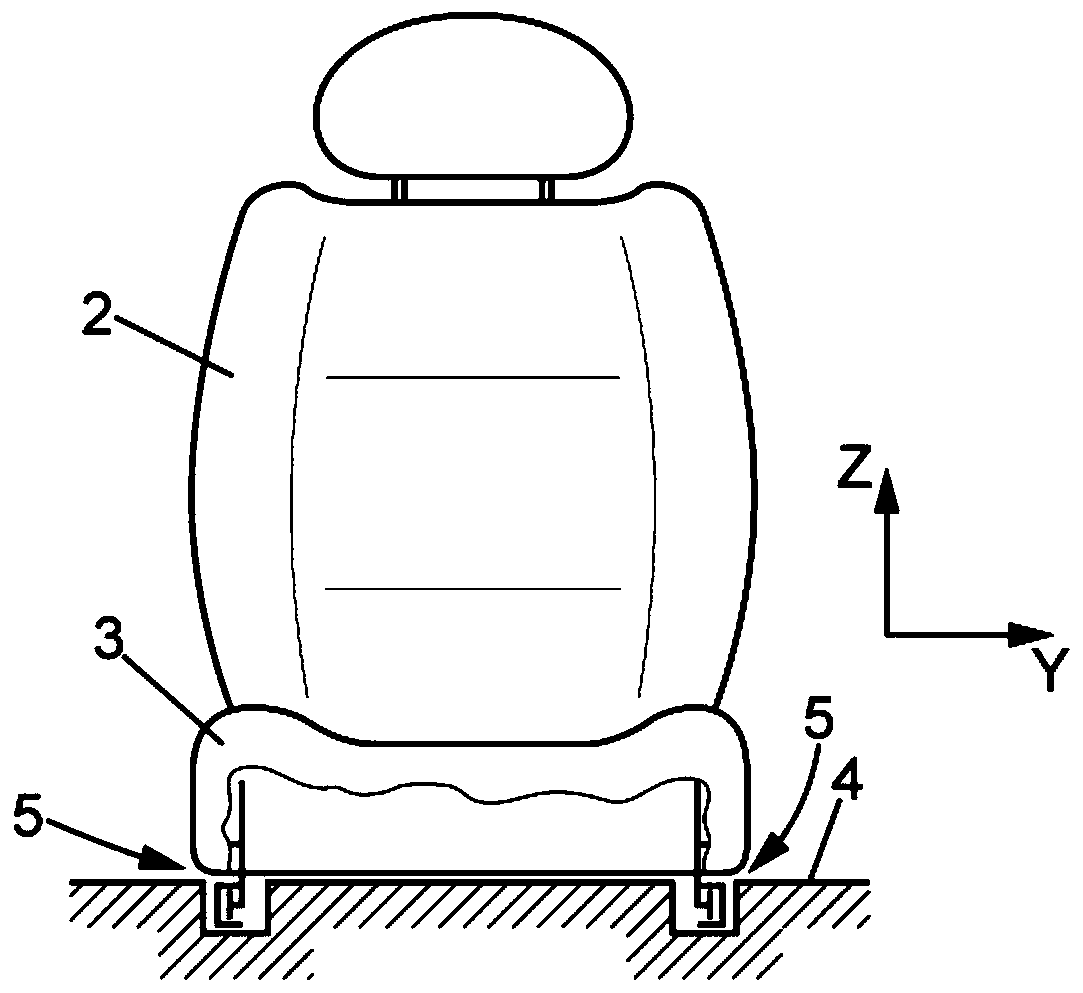

[0042] figure 1 and 2 Shown is a motor vehicle seat 1 comprising a backrest 2 carried by a seating part 3 which is itself mounted on a floor 4 of the vehicle so as to slide in a substantially horizontal longitudinal direction X.

[0043] The seating part 3 is connected to the floor 4 by two parallel rails 5 extending in the longitudinal direction X.

[0044] Each track 5 includes an electric motorized drive mechanism, which will be described below, the motorized drive mechanisms of the two tracks 5 are synchronously controlled by a central processing unit (for example, a microcontroller, etc.) according to received commands, said The commands come in particular from a two-way control button B or similar means operable by the user.

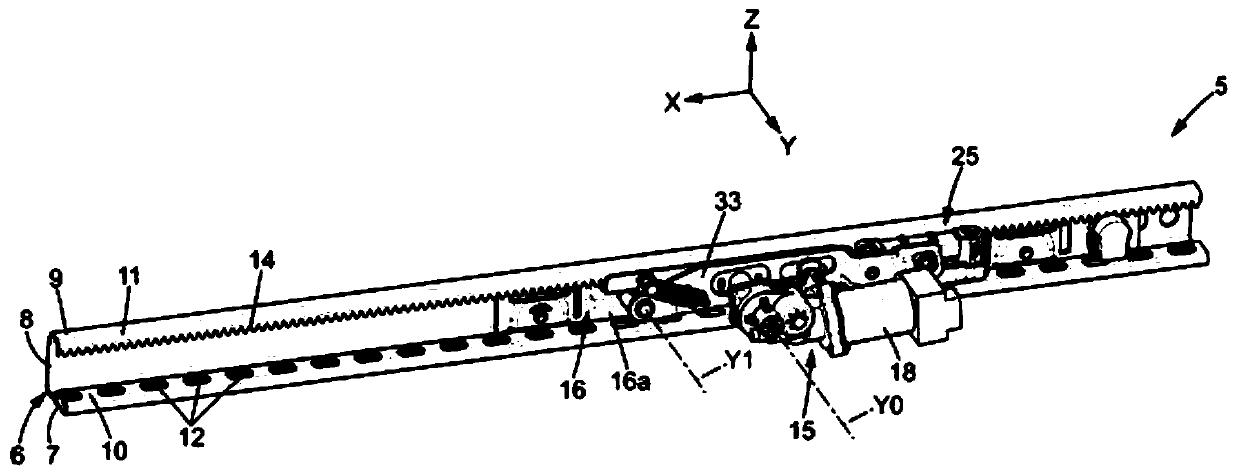

[0045] Such as image 3 As shown, each track 5 comprises a first track member 6 and a second track member 16 mounted on the first track member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com