Transverse knotting mechanism of automatic shoelace tying machine

An automatic technology for tying shoelaces, applied to footwear, shoe ties, clothing, etc., to achieve the effects of high efficiency, short knotting time, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

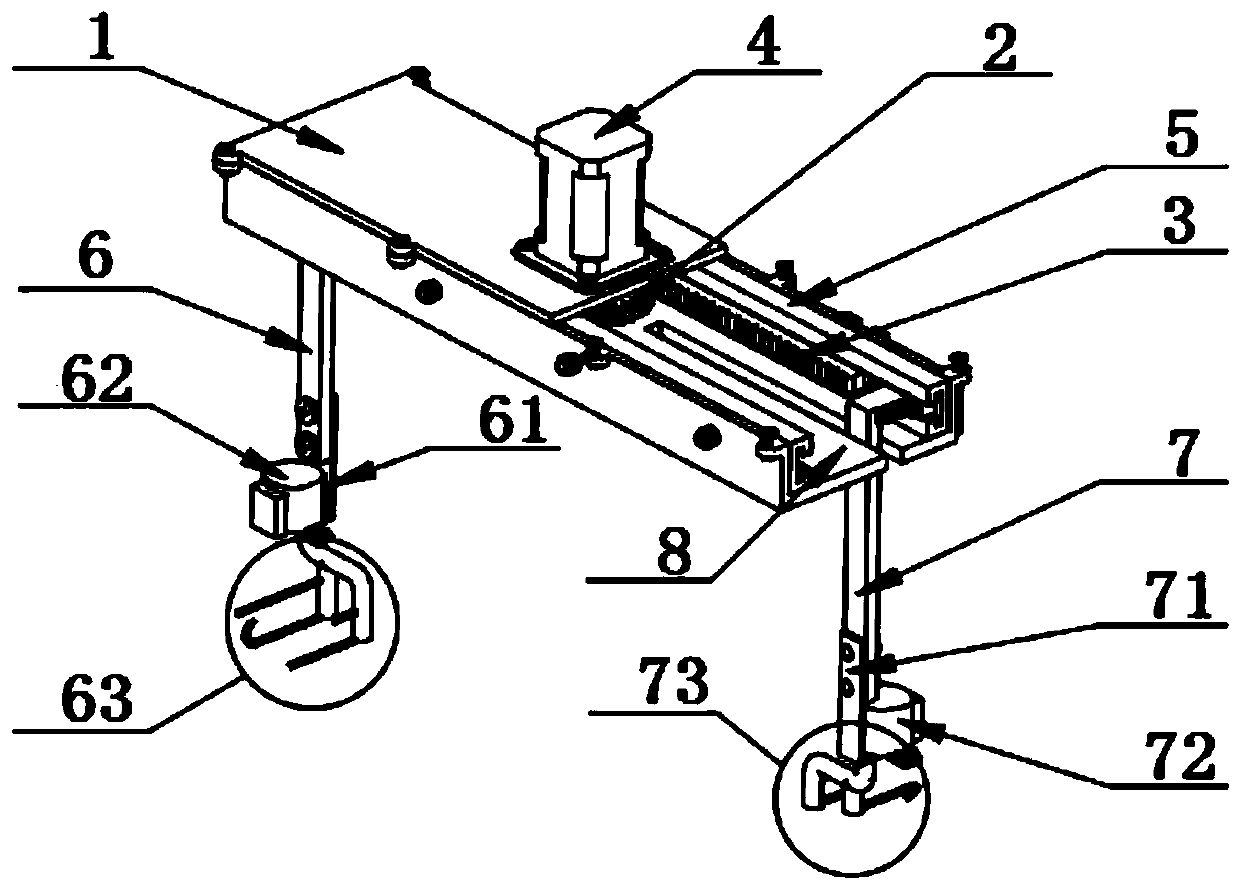

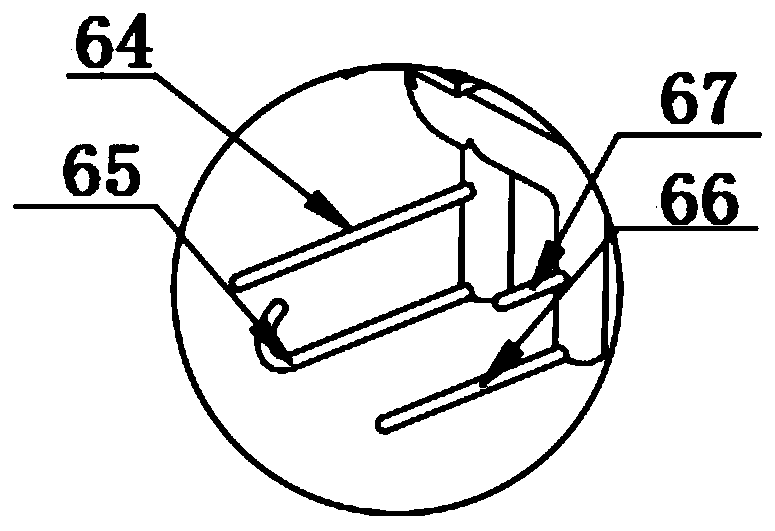

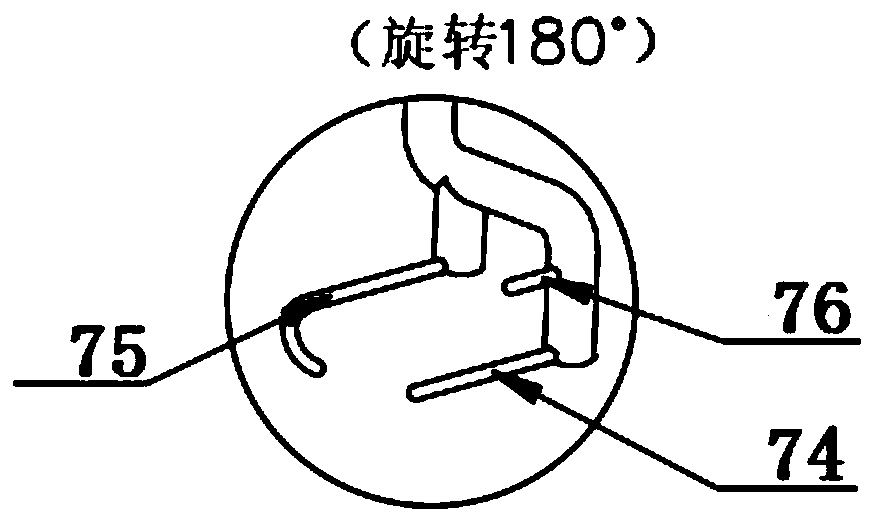

[0033] Embodiment: a kind of horizontal knot mechanism of automatic shoelace machine, as Figure 1-4 As shown, the automatic shoelace machine is provided with a shoe support plate 9 for supporting shoes, and the horizontal knotting mechanism is arranged above the shoe support plate 9 . The horizontal knotting mechanism includes a housing 1, in which a driving gear 2 and two racks 3 meshing with the driving gear 2 are arranged, and the two racks 3 are parallel to each other. A gear drive motor 4 is fixedly installed on the top of the housing 1, the output shaft of the gear drive motor 4 passes through the top surface of the housing 1 and is connected with the rotating shaft of the driving gear 2, and the driving gear 2 can be driven to rotate by the gear drive motor 4; the housing 1 There are guide rails 5 along the length direction on the front and rear sides of the inner side respectively. T-shaped slots are opened on the guide rails 5. The back of the rack 3 matches the T-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com