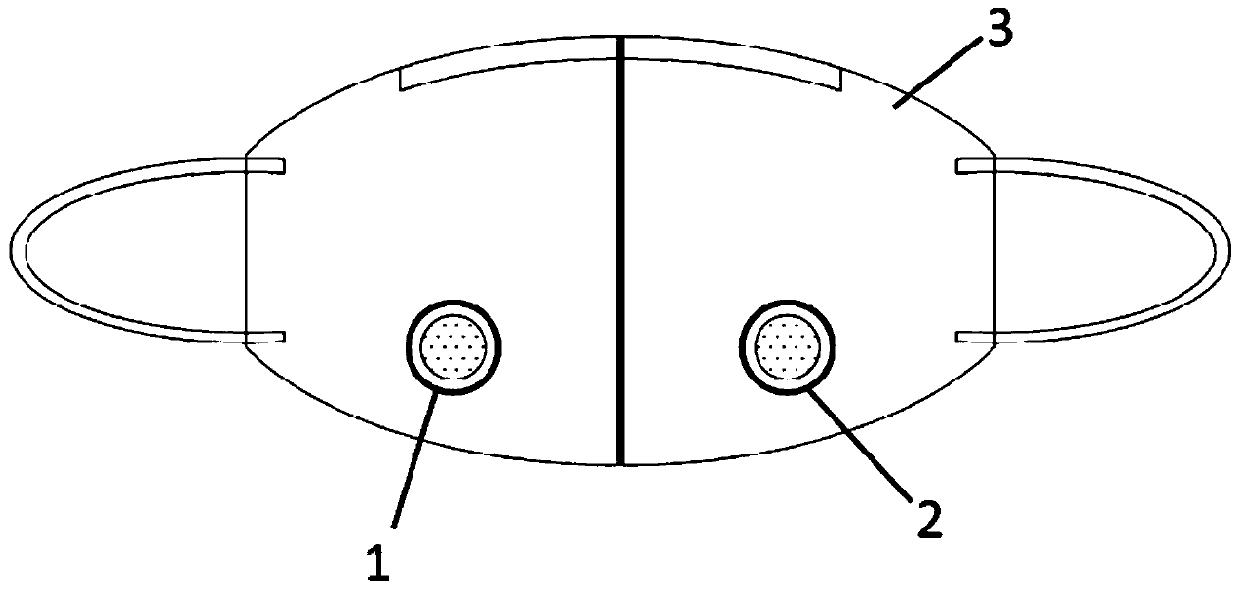

Antibacterial and antiviral master batch for transparent mask, preparation method thereof and antibacterial and antiviral transparent mask

An anti-virus and mask technology, applied in applications, protective clothing, clothing, etc., can solve the problems that it is not easy for patients to establish mutual trust and understanding, the antibacterial and antiviral effect of masks is poor, and the use of masks is inconvenient. Effect, excellent antibacterial, antifungal and antiviral effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

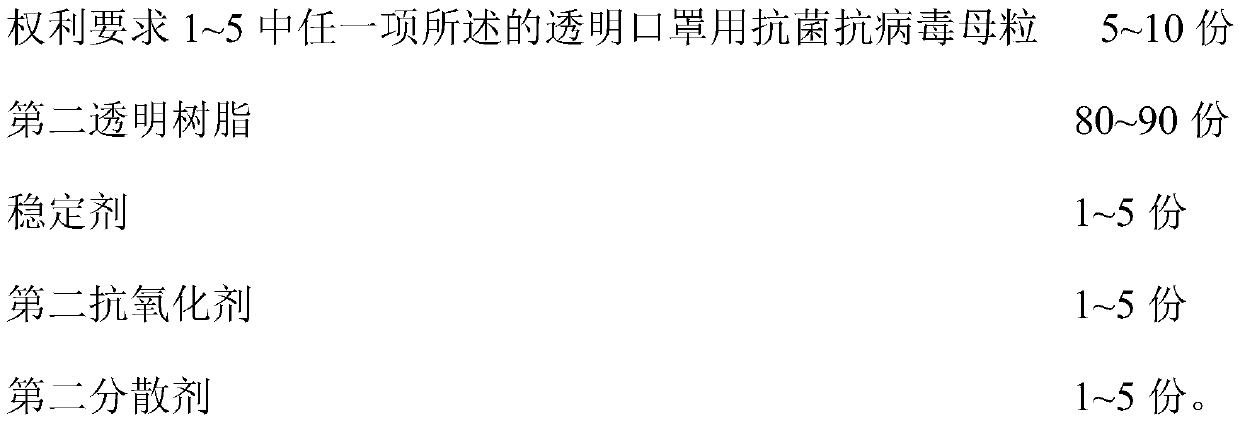

[0062] This embodiment provides a kind of antibacterial and antiviral masterbatch, and the preparation method of antibacterial and antiviral transparent plastic, specifically as follows:

[0063] (1) Preparation of antibacterial and antiviral masterbatch: 88 parts of polyethylene terephthalate, 8 parts of silver-doped nano-bismuth tungstate (the doping amount of silver is 2wt.%), three (2,4 two 2 parts of tert-butylphenyl) phosphite, 2 parts of ethylene bis stearic acid amide, mixed extruding granulation and slicing to obtain masterbatch;

[0064] (2) Preparation of antibacterial and antiviral transparent plastic: 5 parts of antibacterial and antiviral masterbatch, 90 parts of polyethylene terephthalate, 1 part of pentaerythritol, tris(2,4 di-tert-butylphenyl) phosphite 2 parts, 2 parts of ethylene bis stearic acid amide, formed by melting and extruding the raw materials in the above parts by weight after being fully mixed.

Embodiment 2

[0066] This embodiment provides a kind of antibacterial and antiviral masterbatch, and the preparation method of antibacterial and antiviral transparent plastic, specifically as follows:

[0067] (1) Preparation of antibacterial and antiviral masterbatch: 86 parts of biaxially stretched polypropylene, 9 parts of silver-doped nano-titanium dioxide (the doping amount of silver is 0.5wt.%), three (2,4 di-tert-butylbenzene Base) 2 parts of phosphite, 3 parts of polyacrylamide, mixing, extruding, granulating and slicing to obtain masterbatch;

[0068] (2) Preparation of antibacterial and antiviral transparent plastic: 8 parts of antibacterial and antiviral masterbatch, 85 parts of biaxially stretched polypropylene, 2 parts of pentaerythritol stearate, tris(2,4 di-tert-butylphenyl) phosphorous acid 2 parts of ester and 3 parts of polyacrylamide are obtained by melting and extruding the above raw materials in the above parts by weight.

Embodiment 3

[0070] This embodiment provides a kind of antibacterial and antiviral masterbatch, and the preparation method of antibacterial and antiviral transparent plastic, specifically as follows:

[0071] (1) Preparation of antibacterial and antiviral masterbatch: 85 parts of polymethylethylene carbonate, 10 parts of silver-doped nano-zinc oxide (the doping amount of silver is 3wt.%), triethylene glycol bis[β -3 parts of (3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate], 2 parts of ethylene bis stearic acid amide, mixing, extruding, granulating and slicing to obtain master batches;

[0072] (2) Preparation of antibacterial and antiviral transparent plastic: 6 parts of antibacterial and antiviral masterbatch, 88 parts of polymethylethylene carbonate, 2 parts of pentaerythritol oleate, triethylene glycol bis[β-(3-tert-butyl Base-4-hydroxyl-5-methylphenyl) propionate] 2 parts, ethylene bis stearic acid amide 2 parts, melt extruding after fully mixing each raw material of above-mentione...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap