A rapid evaluation method for rapid frosting of protective wax

A protective wax and fast technology, which is applied in the manufacturing field of rubber products, can solve the problems of raw material procurement and formula determination, time-consuming and labor-consuming, chemical composition fluctuations, etc., and achieve simple and easy-to-operate materials and processes, and fast and accurate frosting rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

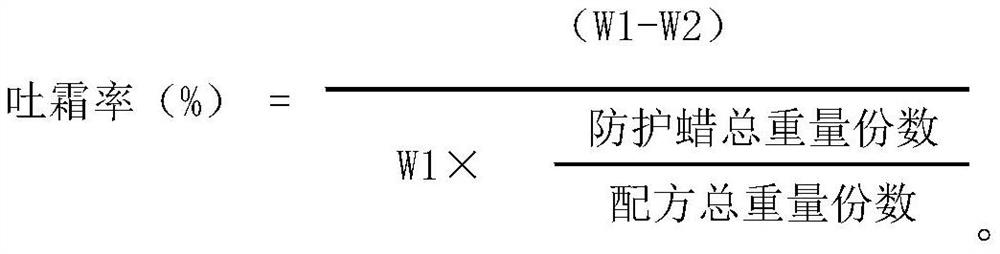

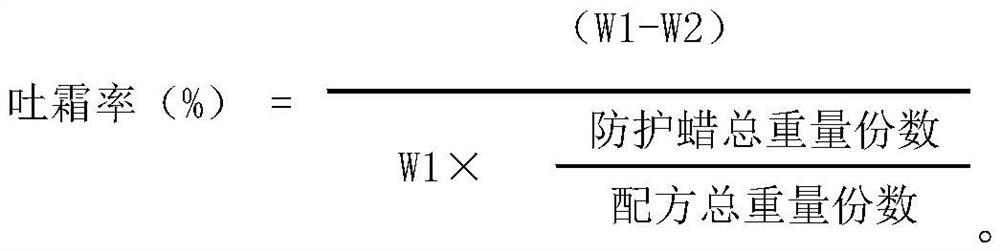

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of above-mentioned formula sizing material, step is as follows:

[0041] In the open mill, the above-mentioned matrix rubber is firstly mixed evenly, and the color, active agent and vulcanization / accelerator are added in turn to knead evenly, and the above-mentioned protective wax test formula rubber is obtained.

[0042] The present invention also discloses a method for quickly evaluating the protective wax spit cream by using the above formula, which includes the following steps:

[0043] Step 1: Cut the protective wax test compound that needs to be tested for frosting into a sample of a specified size, stick cellophane on both sides and place it on a flat vulcanizing machine for vulcanization;

[0044] Step 2: Remove the cellophane from the vulcanized sample, and place it in an oven at 80°C for 3 minutes to 5 minutes to make the appearance color uniform;

[0045] Step 3: After taking dust-proof measures for the above-mentioned samples, place t...

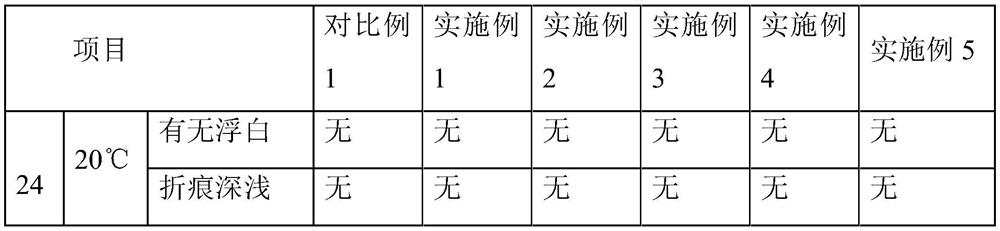

Embodiment 2

[0067] In Example 2, each formula was only placed for 24 hours, and the obvious phenomenon of frosting can be observed, and the result of frosting rate is protective wax A > protective wax B > protective wax C, which is consistent with the theory;

[0068] To sum up: the combination of the test formula of the protective wax and the evaluation method of the present invention can quickly and accurately evaluate the frost of the raw material protective wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com