Turbomachine ring

A technology for turbine engines and supports, applied in the direction of engine functions, engine components, machines/engines, etc., can solve the problems of insufficient resin temperature tolerance, difficult coverage, size dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the present invention more concrete, an example of a turbine engine ring is described in detail below with reference to the accompanying drawings. Remember that the invention is not limited to these examples.

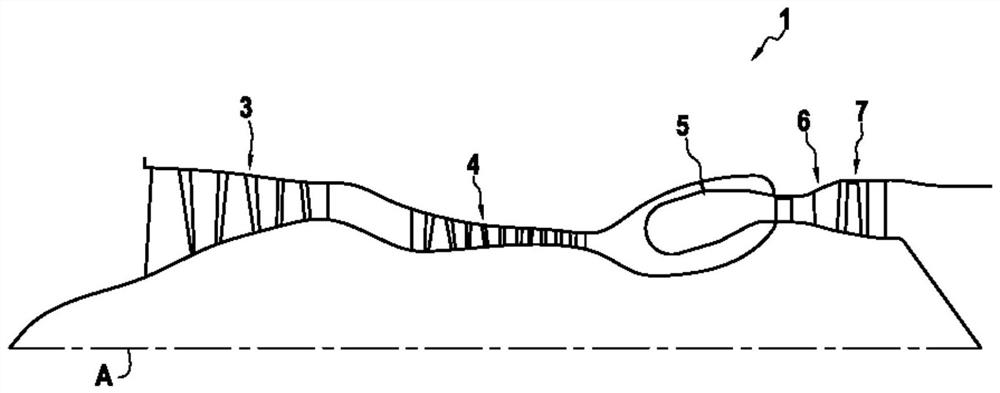

[0055] figure 1 The uniflow turbojet 1 according to the invention is shown in section along a vertical plane passing through its main axis A. It includes a low-pressure compressor 3 , a high-pressure compressor 4 , a combustion chamber 5 , a high-pressure turbine 6 and a low-pressure turbine 7 from upstream to downstream according to the circulation of the air flow.

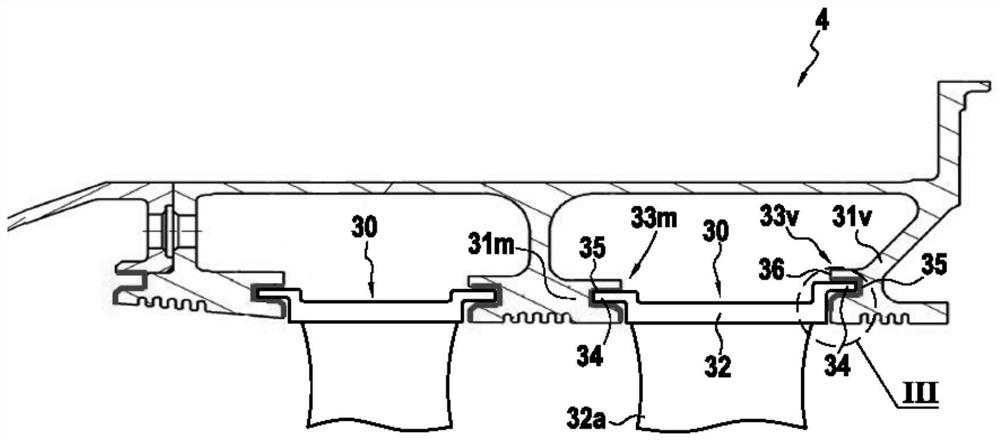

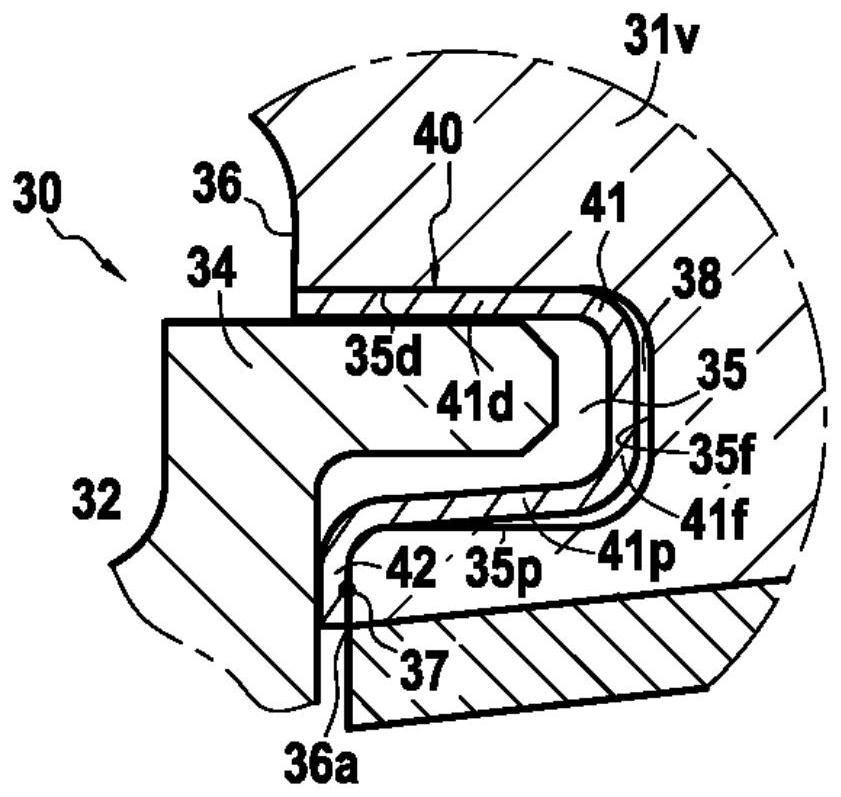

[0056] figure 2 A part of the stator of the high pressure compressor 4 is shown. In this figure, two compressor rings 30 according to the first embodiment are visible. Each compressor ring 30 comprises a generally cylindrical upstream ring support 31m and a downstream ring support 31v and forms an integral part of the casing of the compressor 4: they each form a stream wall fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com