Building facade assembly structure and building facade forming process

A technology of assembly structure and molding process, which is applied in the direction of building components, special structures, etc., can solve the problems of easy fracture or collapse, scattered decorative surface materials, and low strength, so as to reduce the time of working at heights, solve uncontrollable curved surfaces, structural problems, etc. The effect of strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

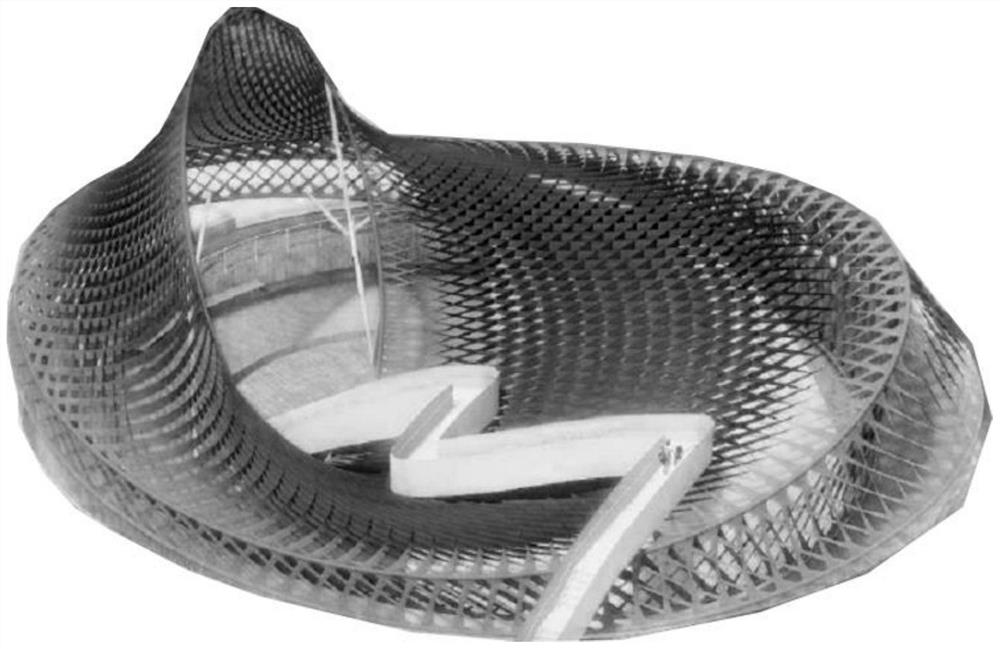

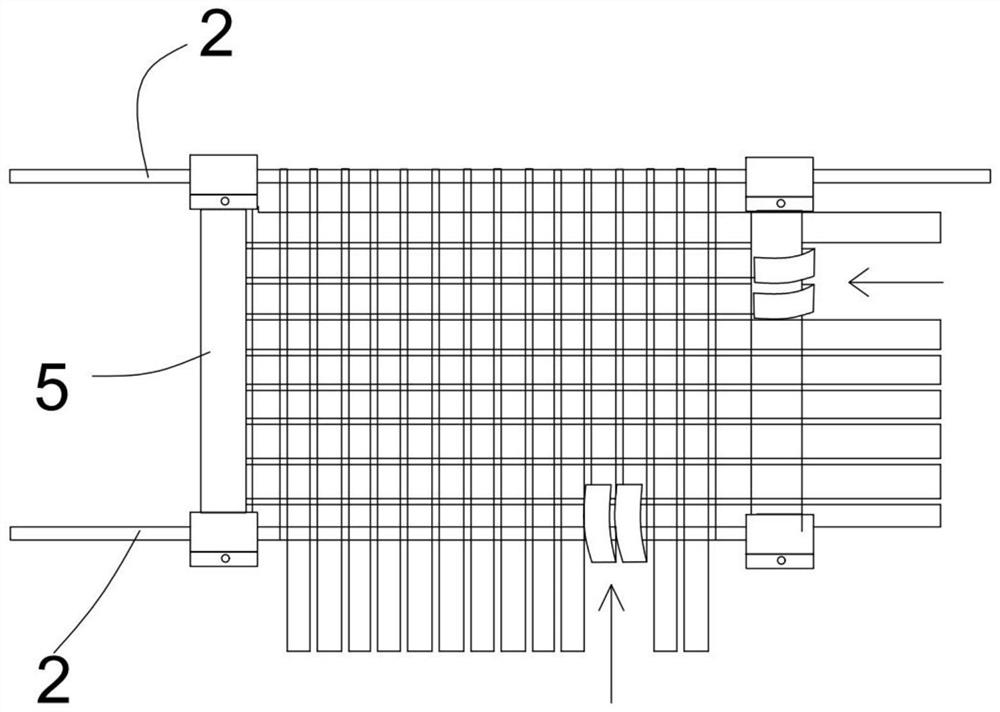

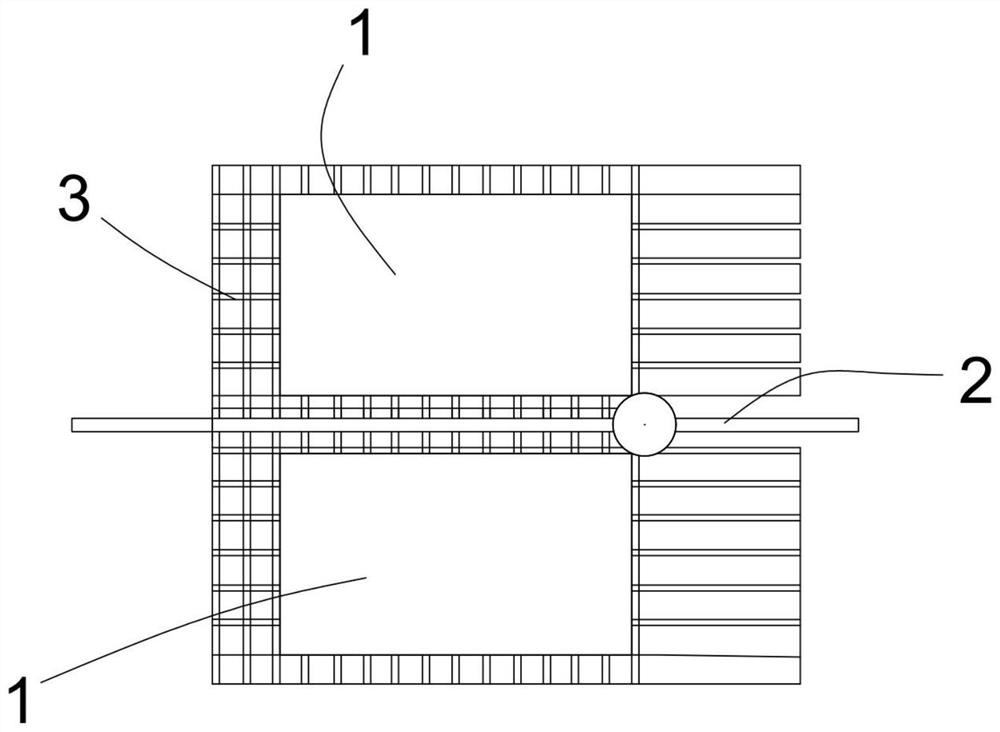

[0029] like figure 2 , image 3 , Figure 4 As shown, the present invention proposes a building facade assembly structure, comprising two elastic inner lining boards 1, one side of the elastic inner lining boards 1 is bonded with a bionic material decorative surface 3, and the elastic inner lining The liner bodies 1 are bonded to each other, and the surface layer 3 decorated with bionic materials is sheathed on the steel cable 2 . The decorative surface layer 3 of the bionic material is made of bionic vines or bamboo slices cross-woven.

[0030] The steel cable 2 includes an upper steel cable 2 and a lower steel cable 2. The upper steel cable 2 and the lower steel cable 2 cooperate with the bionic material decoration surface 3 to form a plane or a curved surface. The steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com