Optical detection equipment

A technology of optical inspection and equipment, which is applied in optical instrument testing, optical testing for flaws/defects, material analysis through optical means, etc. It can solve problems such as high detection difficulty, many types of defects in non-planar areas, and quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order for those skilled in the art to better understand the technical solutions of the present disclosure, an optical detection device provided by the present disclosure will be described in detail below with reference to the accompanying drawings.

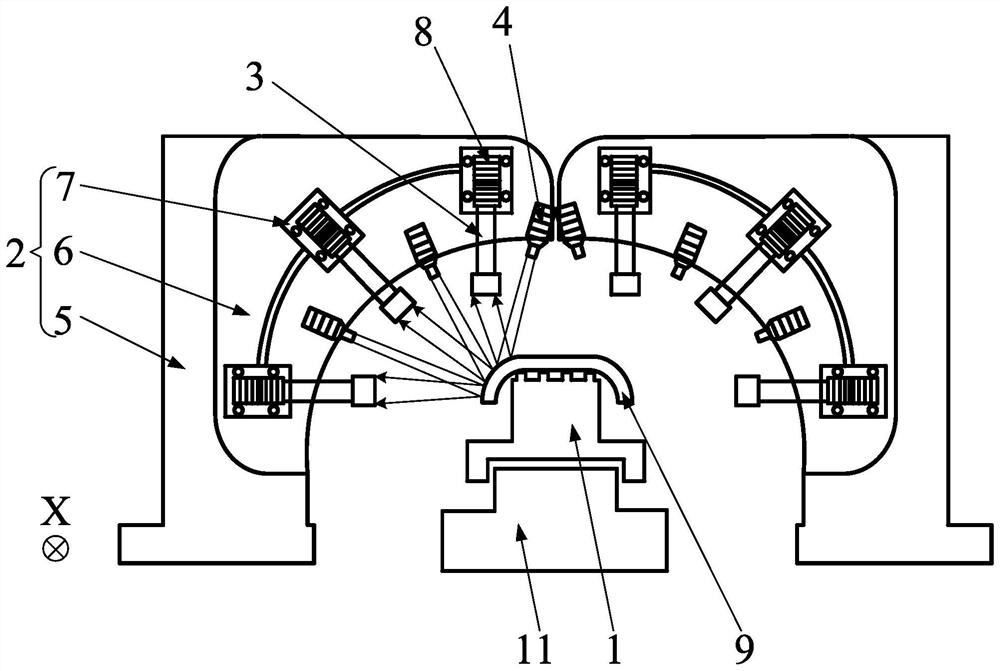

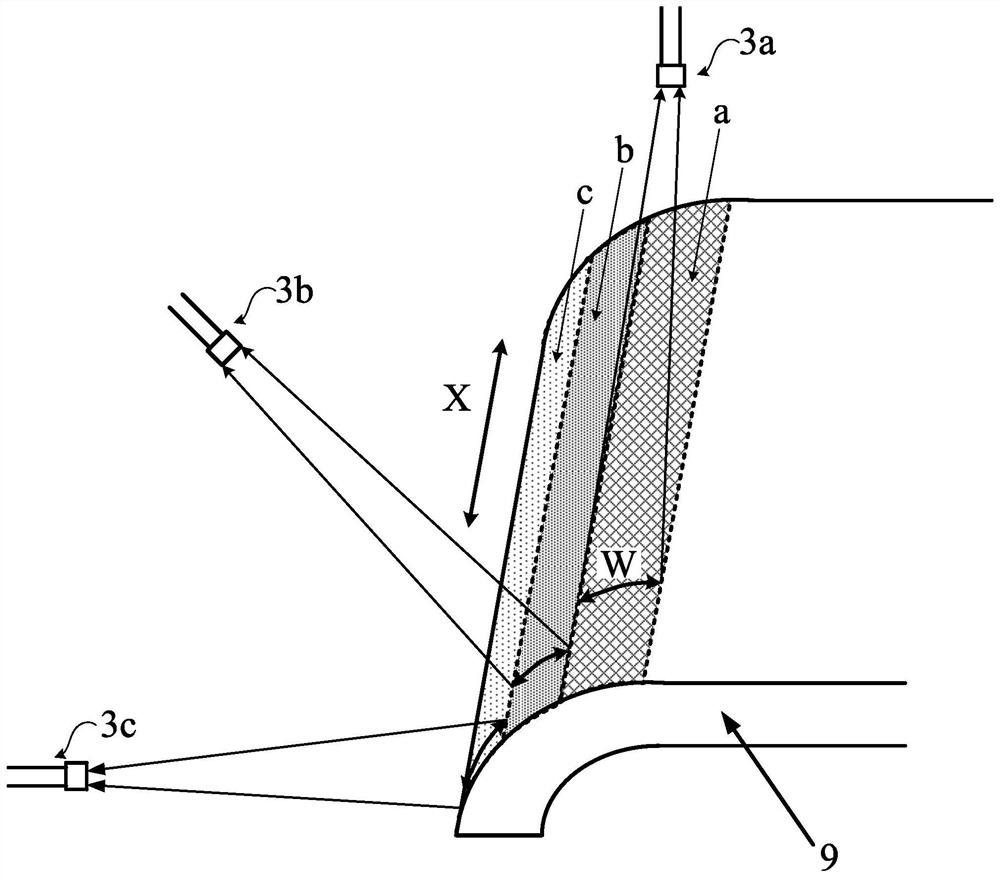

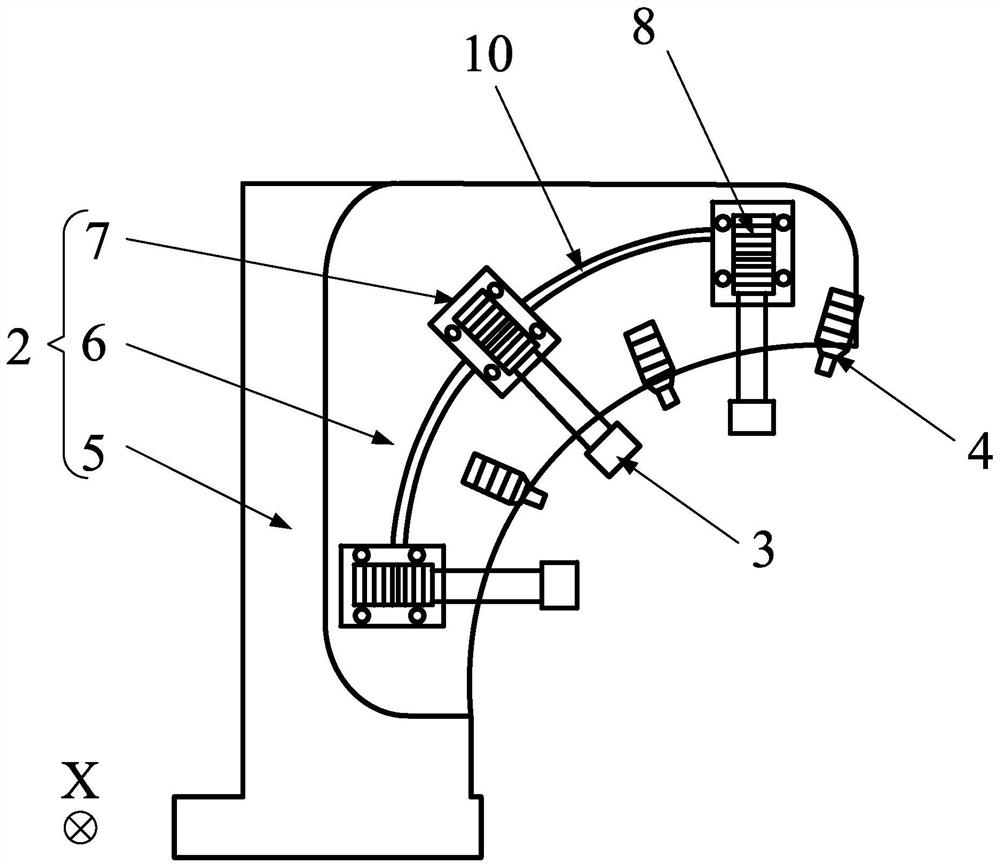

[0030] figure 1 A front view of an optical detection device provided by an embodiment of the present disclosure, such as figure 1 As shown, the optical detection device includes: a stage 1 , a fixed support part 2 , at least one line scan camera 3 and at least one light source 4 . Wherein, the stage 1 is configured to carry the product 9 to be inspected, the fixed support part 2 is located on the side of the stage 1, the line scan camera 3 is arranged on the fixed support part 2, and the line scan camera 3 is configured as an area to be photographed on the surface of the product 9 to be inspected Scan along the preset scanning direction X to obtain corresponding images; the light source 4 is arranged on the fixed suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com