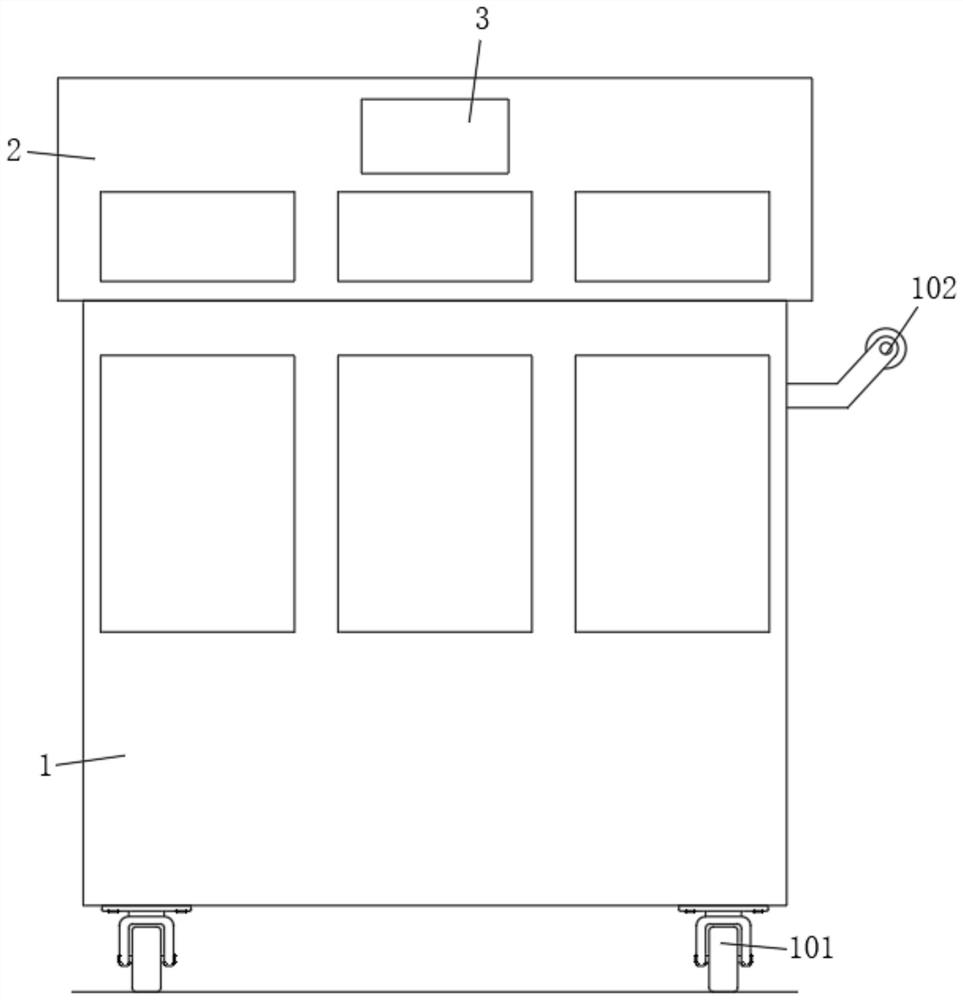

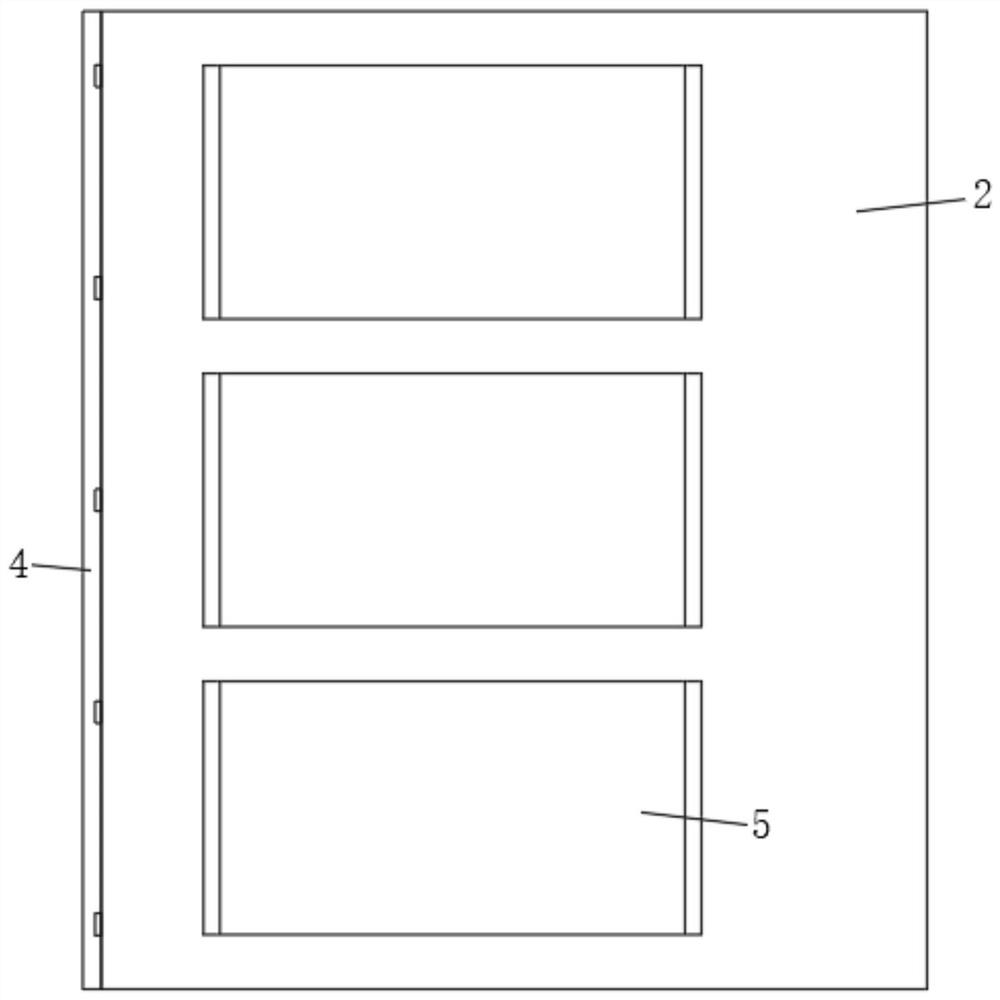

Intelligent garbage can capable of being automatically disinfected

A technology for automatic disinfection and garbage cans, applied in the field of garbage cans, can solve the problems of increased weight of garbage cans, complicated circuit wiring, affecting service life, etc., and achieves the effect of simple circuit installation and wiring, clean internal environment, and guaranteed safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

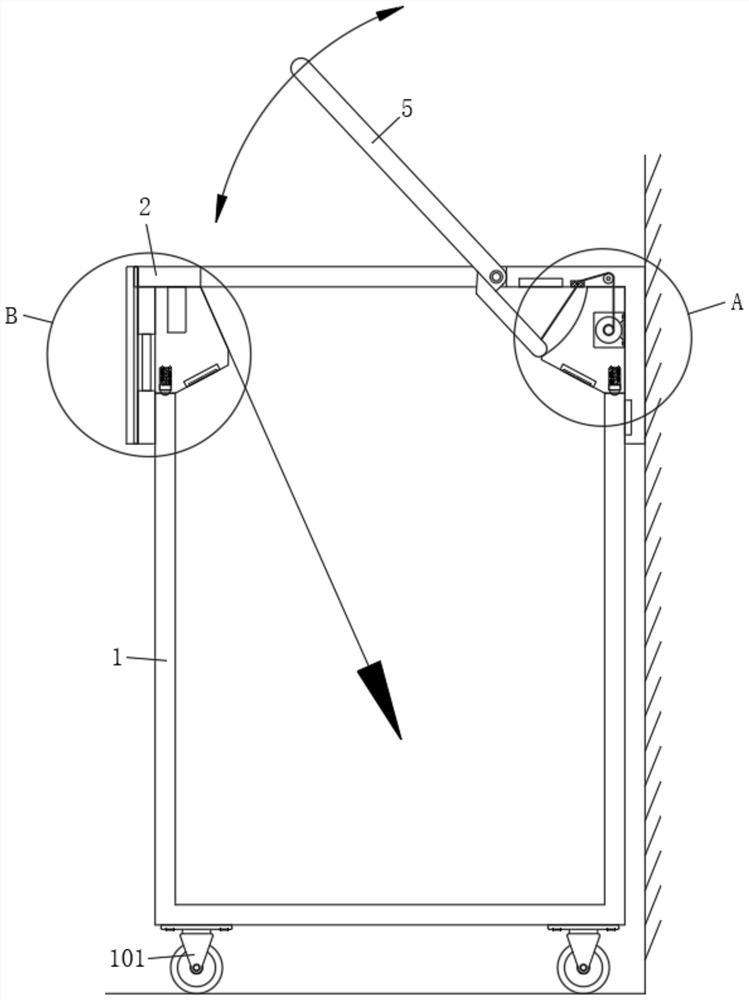

[0059] In this implementation, please continue to Figure 9 As shown, the structure for driving the flip cover 5 to turn over automatically includes a hub motor, and the hub motor is installed on a rotating shaft connected to the flip cover 5 for driving the flip cover 5 to turn over automatically.

[0060] Specifically, the driving principle of this embodiment is: based on the limitation of the counterweight plate 52, the sealing cover plate 51 and the counterweight plate 52 are kept in balance with the rotating shaft as the center of gravity, that is, without any driving force, the overall flip cover 5 maintains a horizontal state. Correspondingly, the overall intelligent trash can can be closed; and under the drive of the hub motor, the flip cover 5 can be turned over to realize Figure 9 status shown. Therefore, based on the counterweight balance, the hub motor can be effectively placed in the minimum load state during reciprocating driving, and the driving energy consump...

no. 2 approach

[0062] In this implementation, please continue to Figure 4 As shown, the structure that drives the flip cover 5 to turn over automatically includes a drive motor 10, a rope winding roller 11, a rope guide roller and a pull rope 6, the driving motor 10 is embedded inside the first guide block 12, and the rope winding roller 11 is rotatably connected to the driving motor At the output end of 10, the stay rope 6 walks around the rope guide roller, and the two ends of the stay rope 6 are respectively fixed with the rope winding roller 11 and the counterweight plate 52. It can be seen from the above that the working principle when the flip cover 5 is opened in cooperation with the induction device 3 is: start the drive motor 10 to drive the rope winding roller 11 to rotate to realize the release of the pull rope 6. At this time, the weight plate 52 is pressed down based on the gravity , to drive the whole flip cover 5 to rotate clockwise (with figure 2 The direction shown is tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com