A kind of mg-ni alloy particle whose surface is inlaid with rare earth element ce and preparation method thereof

A technology of alloy particles and rare earth metals, which is applied in the field of metal materials, can solve the problems of slow start-up of hydrolysis reaction, low reaction activity, slow hydrolysis kinetics of hydrogen production, etc., to avoid activation process, high hydrogen production capacity, and improve alloy mass transfer effect of behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Alloy ingredients:

[0033] Select Ni powder and Mg block, the particle size of Ni powder is 10-30nm, the purity of Ni powder is ≥99.5%, and the mass of Ni powder accounts for 23.5% of the total mass of magnesium and nickel; the purity of Mg block is ≥99.8%, and the mass of Mg block accounts for the total mass of magnesium and nickel. 76.5%, the burning loss of 6% of the total weight of magnesium and nickel added to magnesium;

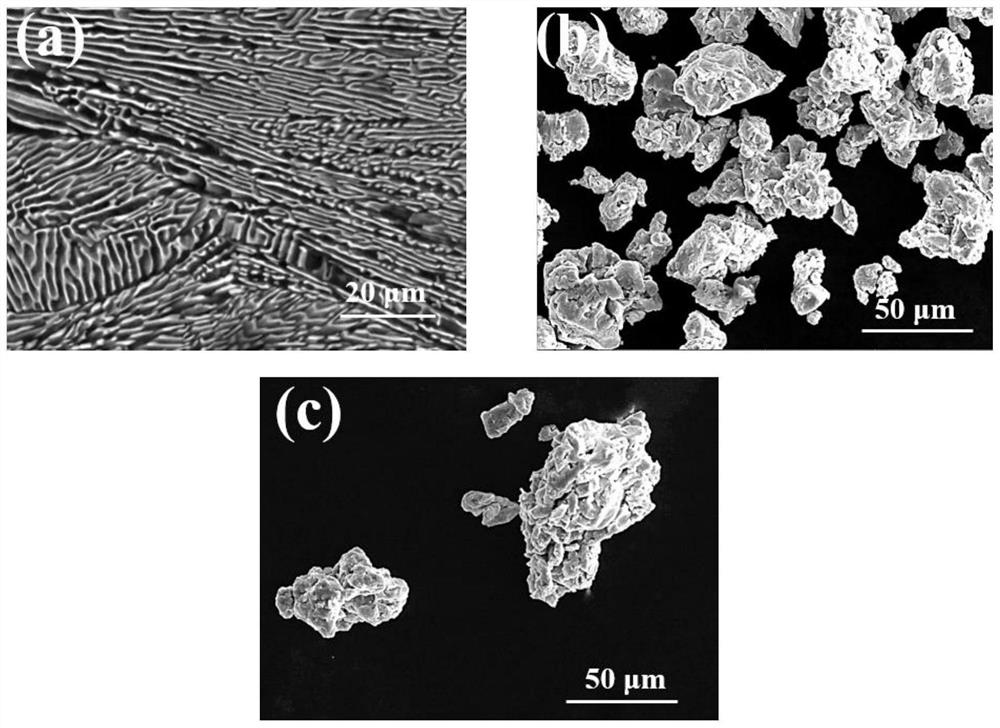

[0034] (2) Mg-Ni alloying:

[0035] Put the magnesium block into a dried high-purity graphite crucible, and under the protection of the covering agent RJ-2, heat the Mg block to 770 ° C to obtain the Mg metal liquid, press the Ni powder into Ni pieces and put them into the Mg metal liquid, Mechanical stirring for 20 min to obtain a Mg-Ni alloy melt, the alloy melt was heated to 880 °C and then kept for 30 min. During the heat preservation process, the alloy melt was stirred, and after the Ni sheet was completely melted, it was cast into a g...

Embodiment 2

[0043] (1) Alloy ingredients:

[0044] Select Ni powder and Mg block, the particle size of Ni powder is 10-30nm, the purity of Ni powder is ≥99.5%, the mass of Ni powder accounts for 10% of the total mass of magnesium and nickel, the purity of Mg block is ≥99.8%, and the mass of Mg block accounts for the total mass of magnesium and nickel. 90%, the burning loss of 2% of the total weight of magnesium and nickel added to magnesium;

[0045] (2) Mg-Ni alloying:

[0046] Put the magnesium block into a dried high-purity graphite crucible, and under the protection of the covering agent RJ-2, heat the Mg block to 750 ° C to obtain Mg molten metal, and press the Ni powder into Ni pieces and put them into the Mg molten metal. Mechanical stirring for 30min to obtain Mg-Ni alloy melt, the alloy melt was heated to 850°C and then kept for 30min, the alloy melt was stirred during the heat preservation process, and after the Ni sheet was completely melted, it was cast into a graphite mold p...

Embodiment 3

[0052] (1) Alloy ingredients:

[0053] Select Ni powder and Mg block, the particle size of Ni powder is 10-30nm, the purity of Ni powder is ≥99.5%, the mass of Ni powder accounts for 55% of the total mass of magnesium and nickel, the purity of Mg block is ≥99.8%, and the mass of Mg block accounts for the total mass of magnesium and nickel. 45%, the burning loss of 8% of the total weight of magnesium and nickel added to magnesium;

[0054] (2) Mg-Ni alloying:

[0055] Put the magnesium block into a dried high-purity graphite crucible, and under the protection of the covering agent RJ-2, heat the Mg block to 790 ° C to obtain the Mg metal liquid, and press the Ni powder into the Ni sheet and put it into the Mg metal liquid, Mechanically stirred for 10 minutes to obtain a Mg-Ni alloy melt. The alloy melt was heated to 900 °C and then kept for 30 minutes. During the heat preservation process, the alloy melt was stirred. After the Ni sheet was completely melted, it was cast into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com