Mg-Ni alloy particles with rare earth element Ce embedded in surface and preparation method thereof

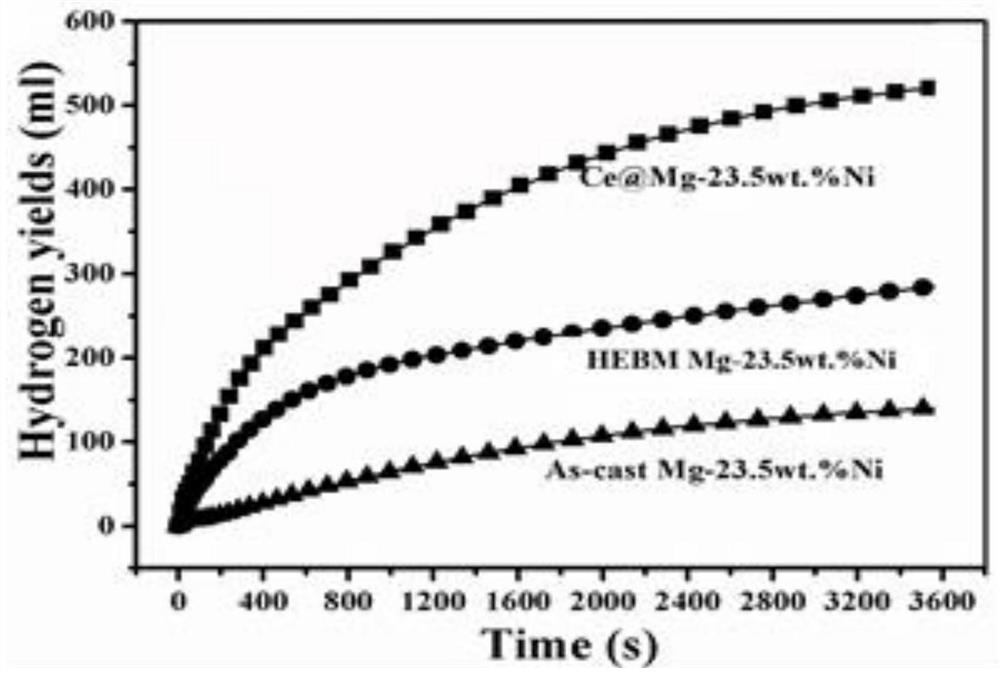

A technology of alloy particles and rare earth metals, applied in the field of metal materials, can solve the problems of slow start of hydrolysis reaction, slow hydrolysis hydrogen production kinetics, low reaction activity, etc., to avoid activation process, improve alloy mass transfer behavior, and high hydrogen production. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

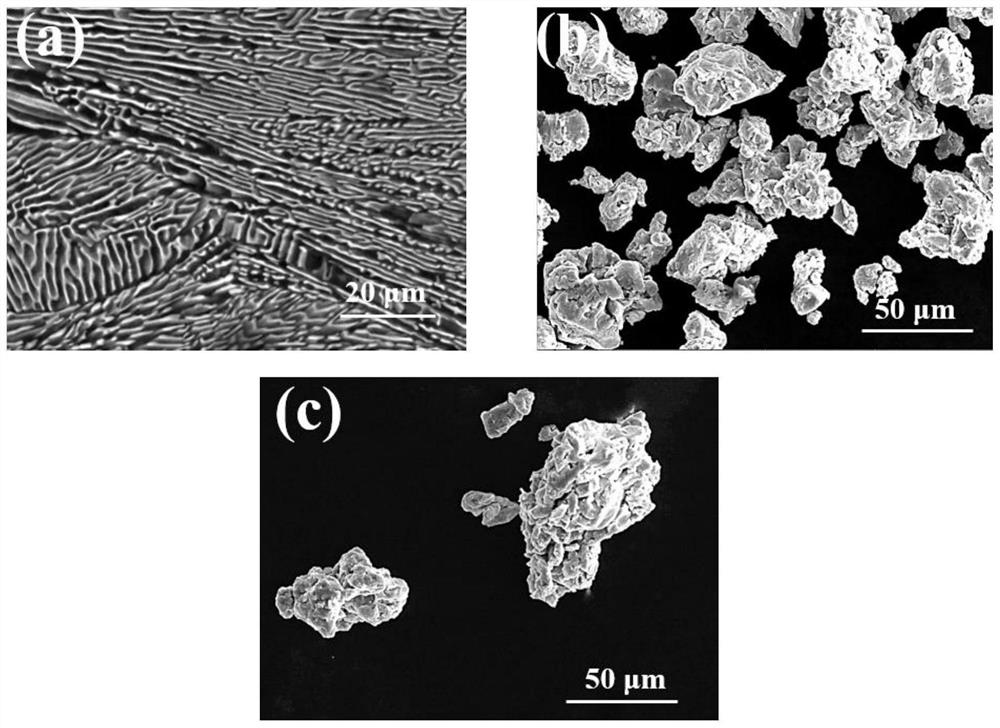

Image

Examples

Embodiment 1

[0032] (1) Alloy ingredients:

[0033] Select Ni powder and Mg block, the particle size of Ni powder is 10-30nm, the purity of Ni powder is ≥99.5%, the mass of Ni powder accounts for 23.5% of the total mass of magnesium and nickel; 76.5%, the burning loss of 6% of the total weight of magnesium and nickel added by magnesium;

[0034] (2) Mg-Ni alloying:

[0035] Put the magnesium block into a dried high-purity graphite crucible, and under the protection of the covering agent RJ-2, heat the Mg block to 770°C to obtain Mg molten metal, press Ni powder into Ni sheet and put it into the Mg molten metal. Stir mechanically for 20 minutes to obtain the Mg-Ni alloy melt, raise the temperature of the alloy melt to 880°C and keep it warm for 30 minutes, stir the alloy melt during the heat preservation process, and cast it into a graphite mold preheated to 240°C after the Ni sheet is completely melted , naturally cooling to room temperature to obtain a Mg-Ni alloy ingot, grinding and re...

Embodiment 2

[0043] (1) Alloy ingredients:

[0044] Select Ni powder and Mg block, the particle size of Ni powder is 10-30nm, the purity of Ni powder is ≥99.5%, the mass of Ni powder accounts for 10% of the total mass of magnesium and nickel, the purity of Mg block is ≥99.8%, and the mass of Mg block accounts for 10% of the total mass of magnesium and nickel. 90%, the burning loss of 2% of the total weight of magnesium and nickel added to magnesium;

[0045] (2) Mg-Ni alloying:

[0046] Put the magnesium block into a dried high-purity graphite crucible, and under the protection of the covering agent RJ-2, heat the Mg block to 750°C to obtain Mg molten metal, press Ni powder into Ni sheet and put it into the Mg molten metal. Stir mechanically for 30 minutes to obtain a Mg-Ni alloy melt, raise the temperature of the alloy melt to 850°C and keep it warm for 30 minutes, stir the alloy melt during the heat preservation process, and cast it into a graphite mold preheated to 240°C after the Ni s...

Embodiment 3

[0052] (1) Alloy ingredients:

[0053] Select Ni powder and Mg block, the particle size of Ni powder is 10-30nm, the purity of Ni powder is ≥99.5%, the mass of Ni powder accounts for 55% of the total mass of magnesium and nickel, the purity of Mg block is ≥99.8%, and the mass of Mg block accounts for 10% of the total mass of magnesium and nickel. 45%, the burning loss of 8% of the total weight of magnesium and nickel added by magnesium;

[0054] (2) Mg-Ni alloying:

[0055] Put the magnesium block into a dried high-purity graphite crucible, and under the protection of the covering agent RJ-2, heat the Mg block to 790°C to obtain Mg molten metal, press Ni powder into Ni sheet and put it into the Mg molten metal. Stir mechanically for 10 minutes to obtain a Mg-Ni alloy melt, raise the temperature of the alloy melt to 900°C and keep it warm for 30 minutes, stir the alloy melt during the heat preservation process, and cast it into a graphite mold preheated to 240°C after the Ni s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com