Automobile lamp inner lens and manufacturing method thereof

A production method and a technology for light distribution mirrors, which can be applied in the direction of headlights, motor vehicles, road vehicles, etc., and can solve the problems of rigidity, single shape, and monotony.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

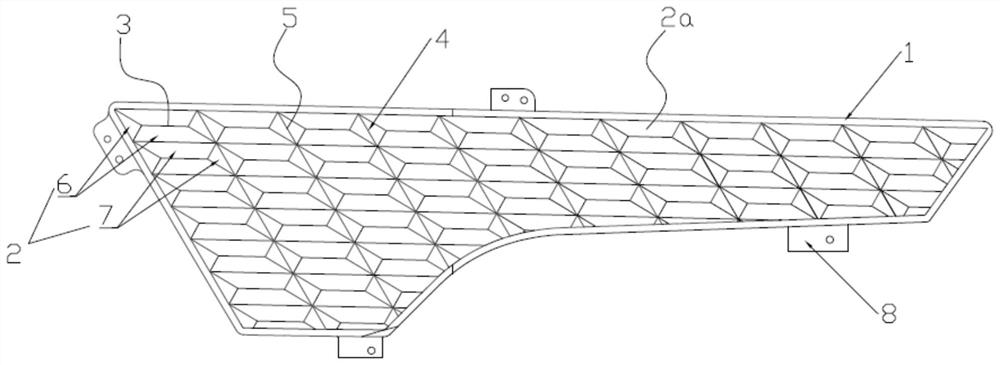

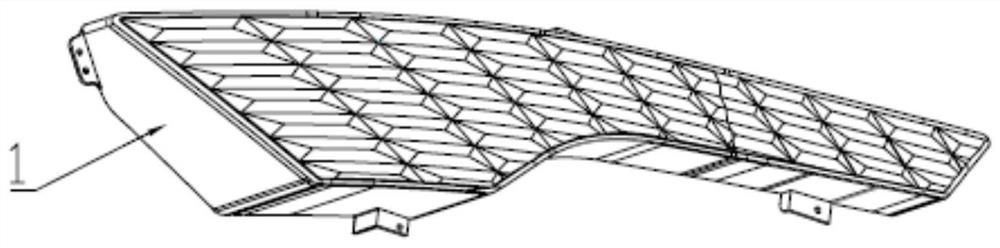

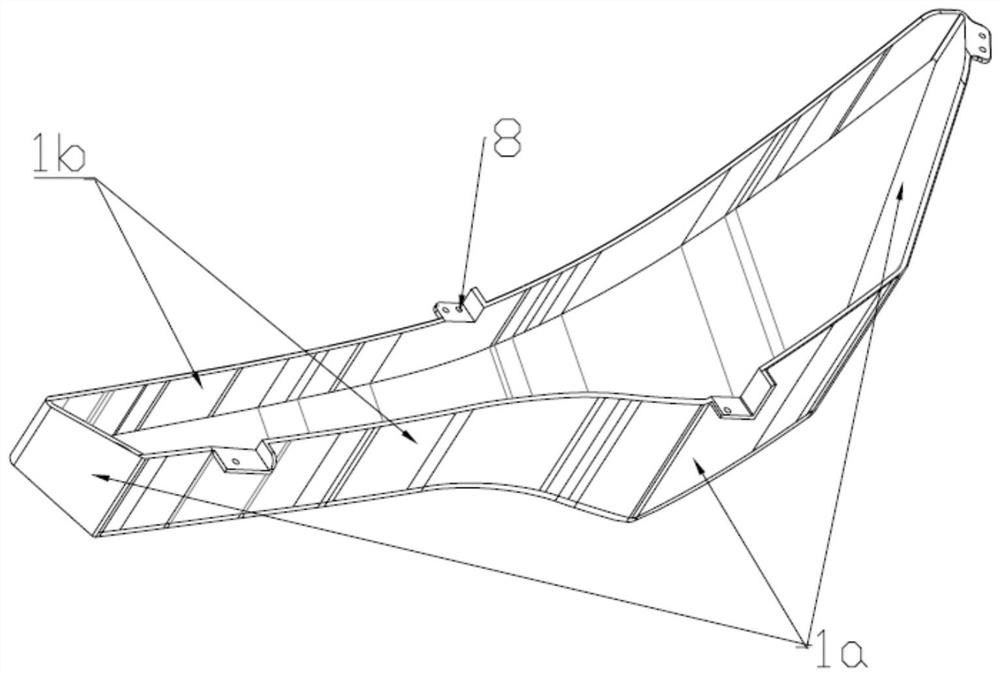

[0034] see Figure 1-7 As shown, the present invention provides an inner light distribution mirror for a car lamp, which is arranged on the front or side of the position lamp of the car lamp, and includes a main body 1 of the inner light distribution mirror, on which a plurality of refracting parts 2 are arranged. The refraction part 2 is connected into a prism-shaped convex structure 3 by several slopes 2a, and at least two slopes 2a on the prism-shaped convex structure 3 are not completely the same, and a boundary line 4 is shared between two adjacent refraction parts 2, adjacent A recessed portion 5 is formed between the surfaces of the two refracting portions 2 sharing the boundary line 4 . Each refraction portion 2 includes a light-transmitting area 6 and a shielding area 7, and each of the light-transmitting area 6 and the shielding area 7 is composed of at least one slope 2a.

[0035] Through a plurality of refraction parts 2 with prism-shaped convex structures 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com