An Abrasive Belt Grinding Mechanism with Adjustable Contact Rigidity

An abrasive belt grinding and contact stiffness technology, applied in abrasive belt grinders, grinding/polishing equipment, grinders, etc., can solve the problem of online control of difficult surface processing with different thicknesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

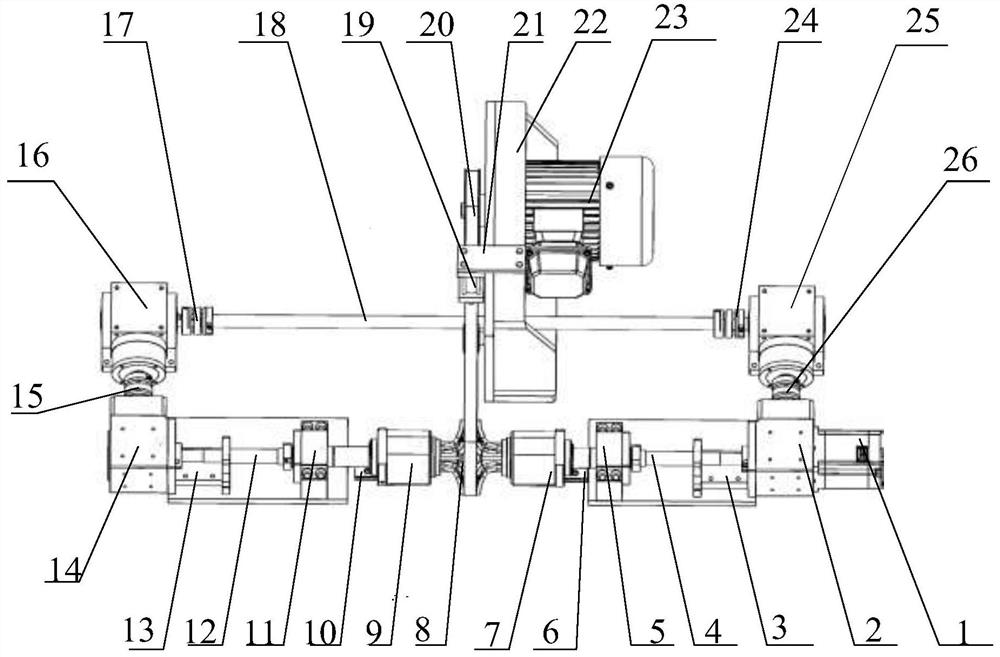

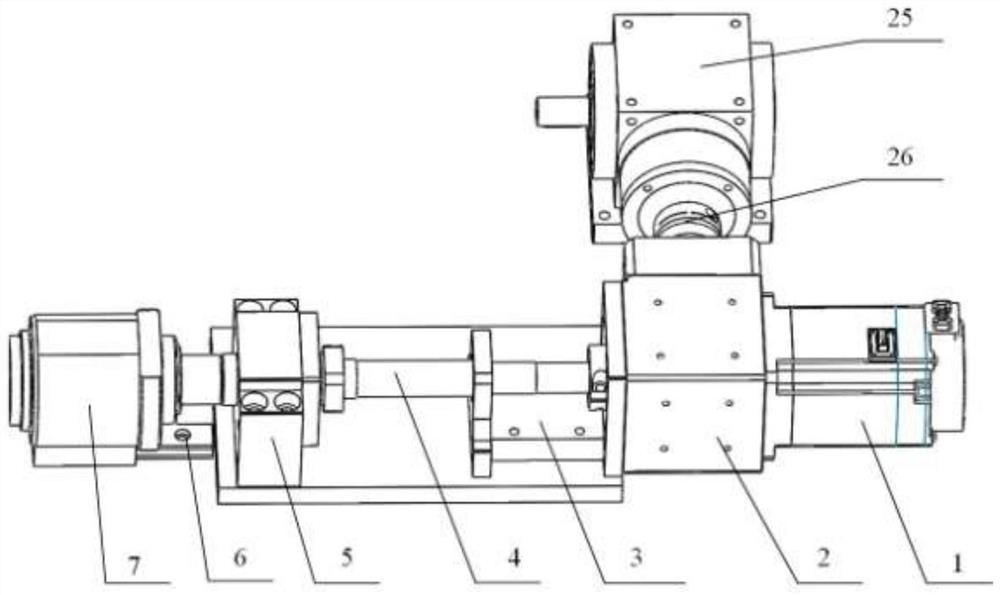

[0026] The present invention is an abrasive belt grinding mechanism with adjustable contact stiffness, the structure is as follows figure 1 As shown, it includes the servo control module and the cutting motion module erected on the upper part of the servo control module. The servo control module drives the three-axis commutator 2, the two-axis commutator A14, the two-axis commutator B16, and the two-axis commutator through the servo motor 1. The commutator C25 converts the direction of rotation, so that the screw A4 and the screw B12 produce rotational motion in different directions, and drives the nut pair A7 and the nut pair B9 to make a linear motion on the guide rail A6 and guide rail B10, and then drives the cutting motion module. The abrasive belt grinds the contact wheel for stiffness adjustment.

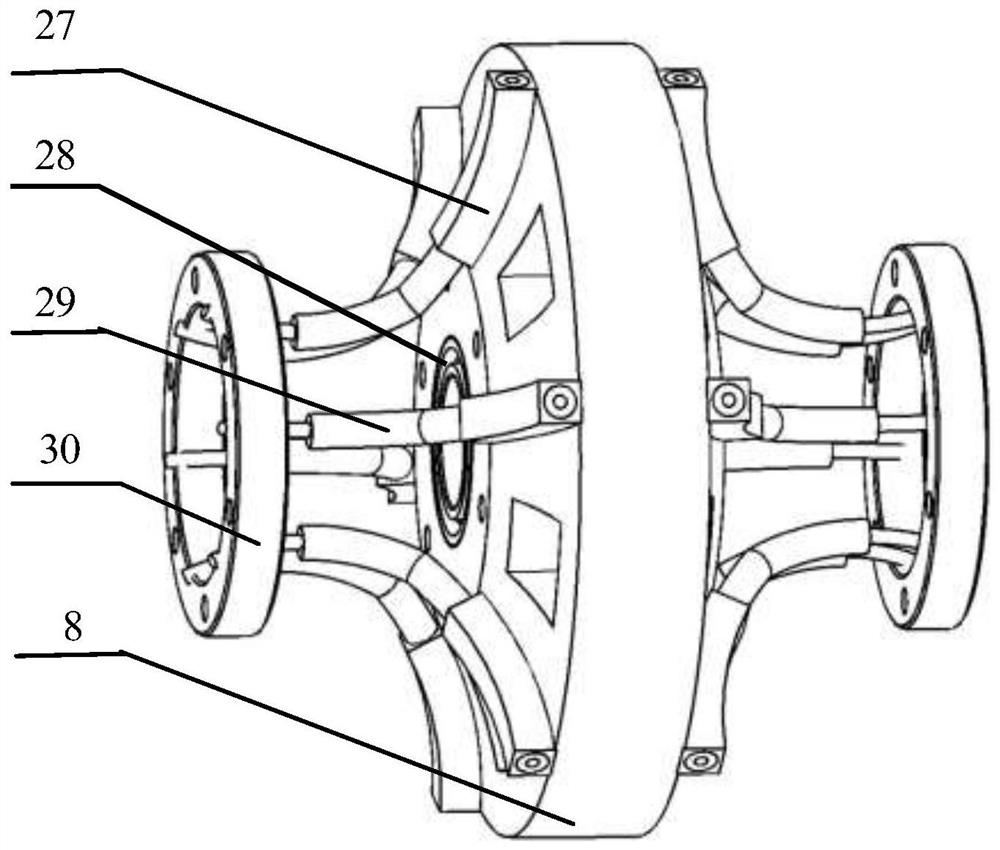

[0027] The specific structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com