An active compliance wheel-shaped abrasive belt mechanism

A kind of abrasive belt and wheel-shaped technology, which is applied in the direction of grinding drive device, grinding machine parts, metal processing equipment, etc., can solve the problem of online control of the processing process of difficult and non-uniform thickness thin-walled parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

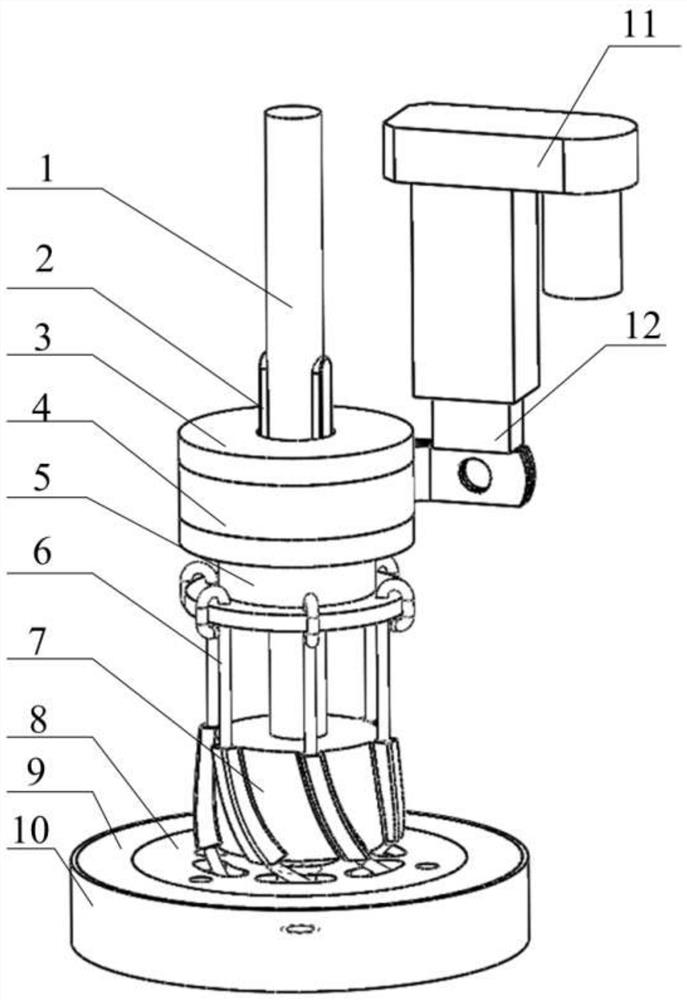

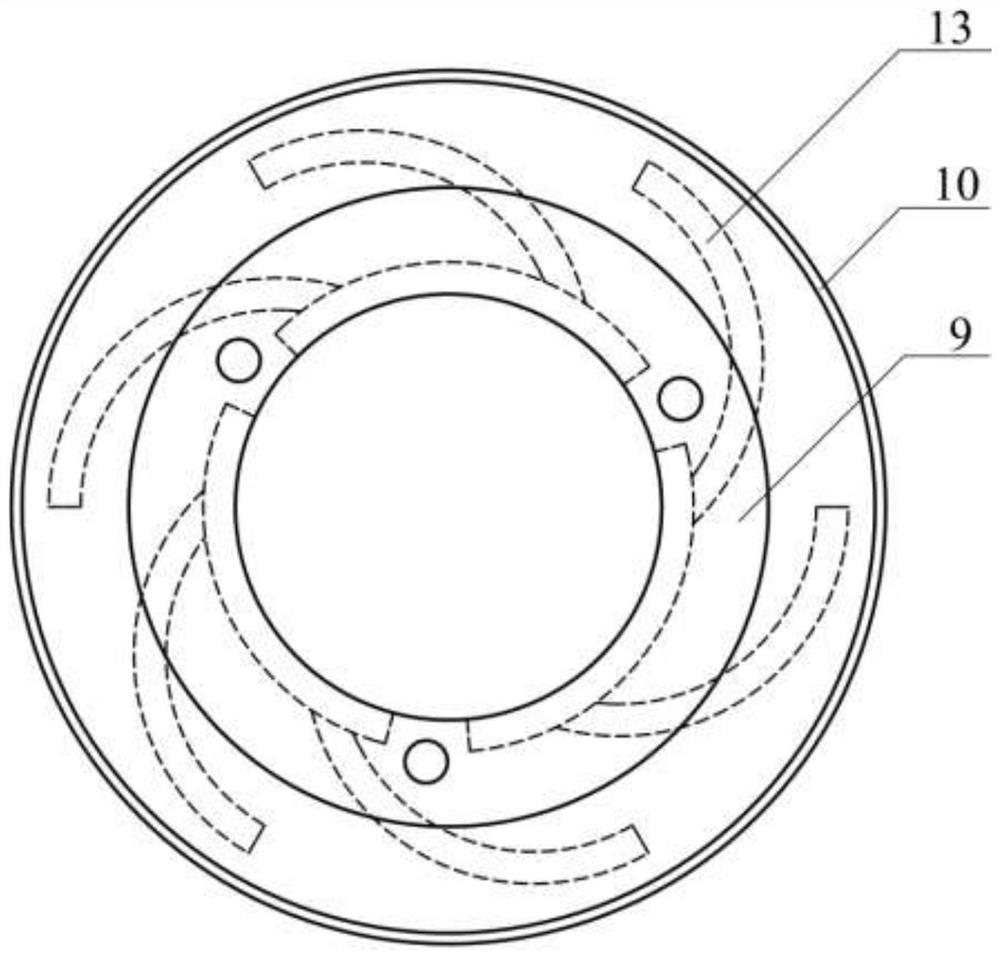

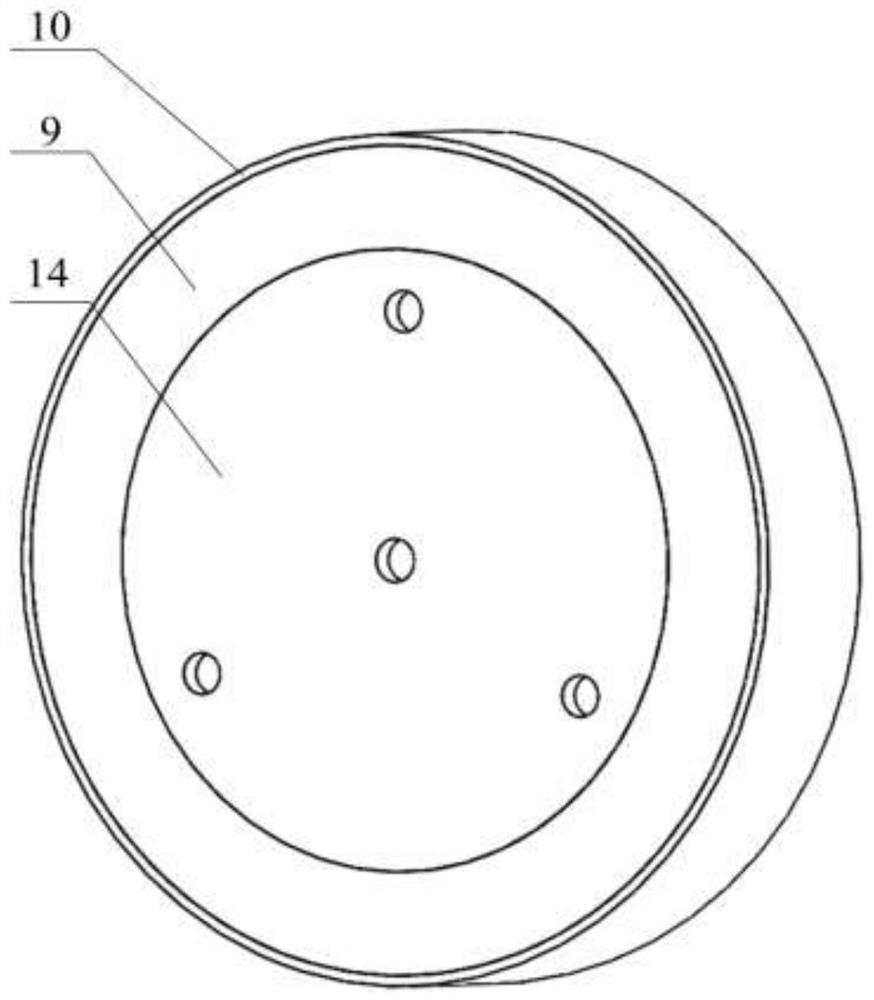

[0025] The present invention is an active compliance wheel-shaped abrasive belt mechanism, the structure of which is as follows: Figure 1 to Figure 5 As shown, it includes a grinding contact wheel 9, the outer circumference of the grinding contact wheel 9 is covered with an abrasive belt 10, the inside of the grinding contact wheel 9 is provided with a disc 8 on the wheel, and the center of the disc 8 on the wheel is provided with a rib reversing 7, the central position of the rib commutator 7 is interspersed with a rotating main shaft 1, the rotating main shaft 1 and the rib commutator 7 adopt an interference fit, the upper part of the rotating main shaft 1 is also provided with a bearing structure, and the bottom of the bearing structure and the flange The disc 5 is fixedly connected, a number of reinforcing ribs 6 are evenly arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com