Method of cutting square grooves in building walls or floors

A technology for building walls and floors, which is applied in the field of opening square grooves on building walls or floors, and can solve problems such as mismatched size design of square grooves, damage to walls or floors, and low efficiency of square grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

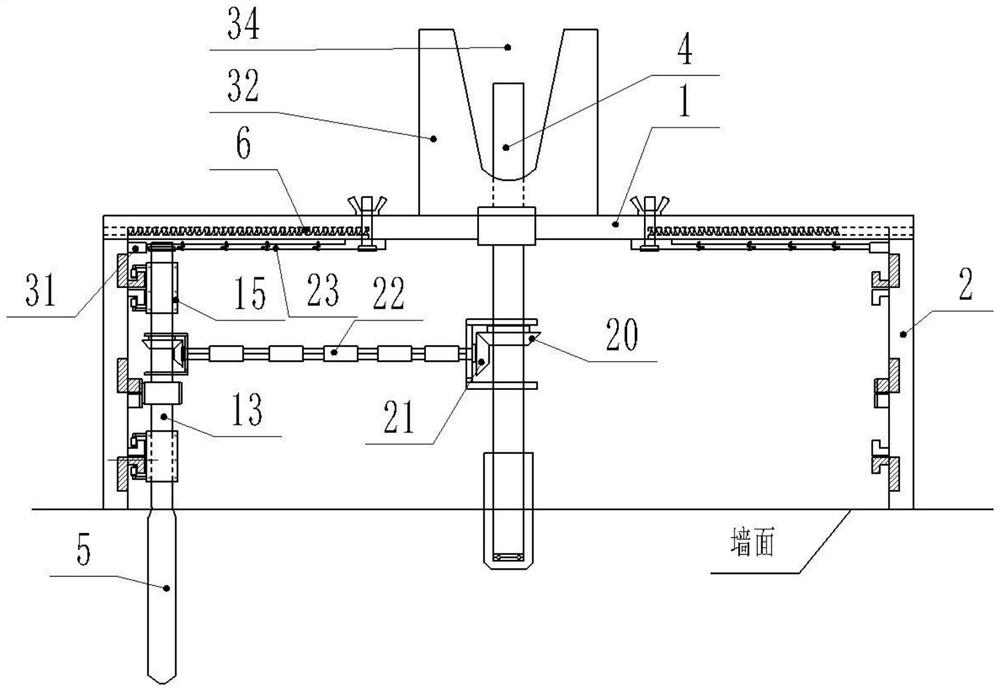

[0047] like Figure 1-14 Shown, the present invention opens the method for square groove on building wall or floor, comprises steps:

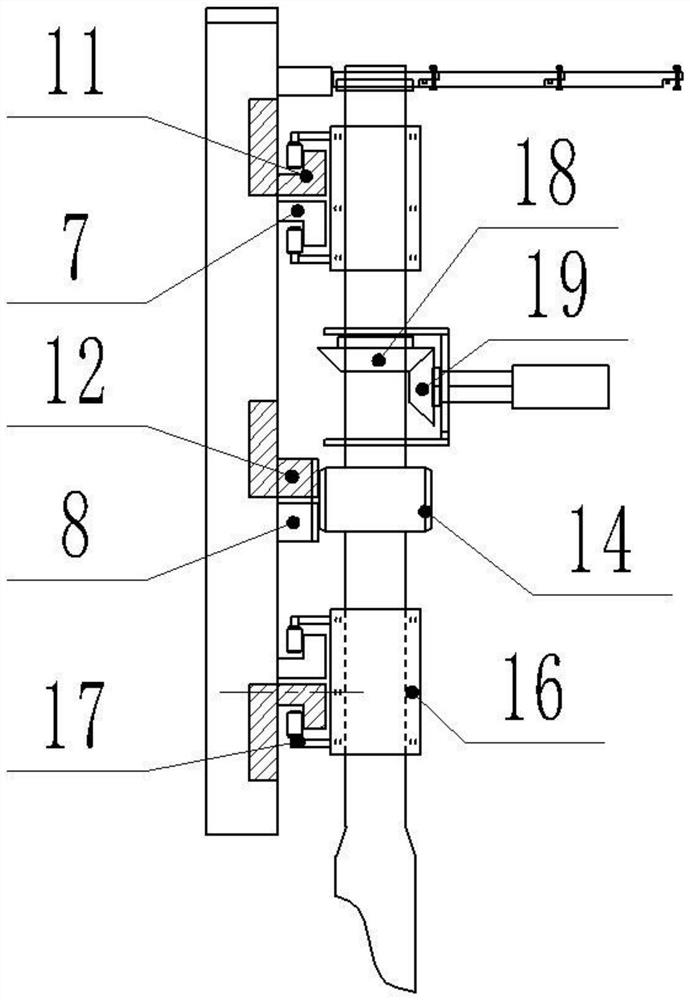

[0048] Step 1. Set the positioning top frame 1. A central positioning shaft 4 is inserted in the center of the positioning top frame 1. The four sides of the positioning top frame 1 are respectively connected with sliding side frames 2, and between the positioning top frame 1 and the sliding side A tension spring 6 is connected between the plate frames 2, and two opposite L-shaped side plate guide rails 7 and a side plate bar tooth 8 are arranged on the inner surface of the sliding side plate frame 2. On the L-shaped side plate guide rail 7 and the side Side plate chute 9 is provided on the sliding side plate frame 2 on one side of the slat teeth 8;

[0049] Step 2. Set up the right-angle plate connecting frame 3. On the two connecting end surfaces of the right-angle plate connecting frame 3 and the side plate chute 9 on the sliding side plate...

Embodiment 2

[0067] like Figure 1-14 Shown, the present invention opens the method for square groove on building wall or floor, on the basis of embodiment 1, is provided with positioning ruler 23 on the corresponding position of each sliding side plate frame 2 on positioning roof frame 1, described The positioning ruler 23 includes an installation positioning block 24 and a chi section 25, the multi-section chi section 25 is connected end to end, and the end chi section 25 is connected to the installation positioning block 24, and the installation positioning block 24 is installed on the positioning roof frame 1 by adjusting bolts;

[0068] The connecting head of the chi section 25 is provided with a step platform, and the butt ends of the two connected chi sections 25 are connected by a pin bar 26, and one end of the pin bar 26 is provided with an extruding spring 27, and the two parts are connected by the extruding spring 27. The ends of the terraces connecting the length sections 25 are ...

Embodiment 3

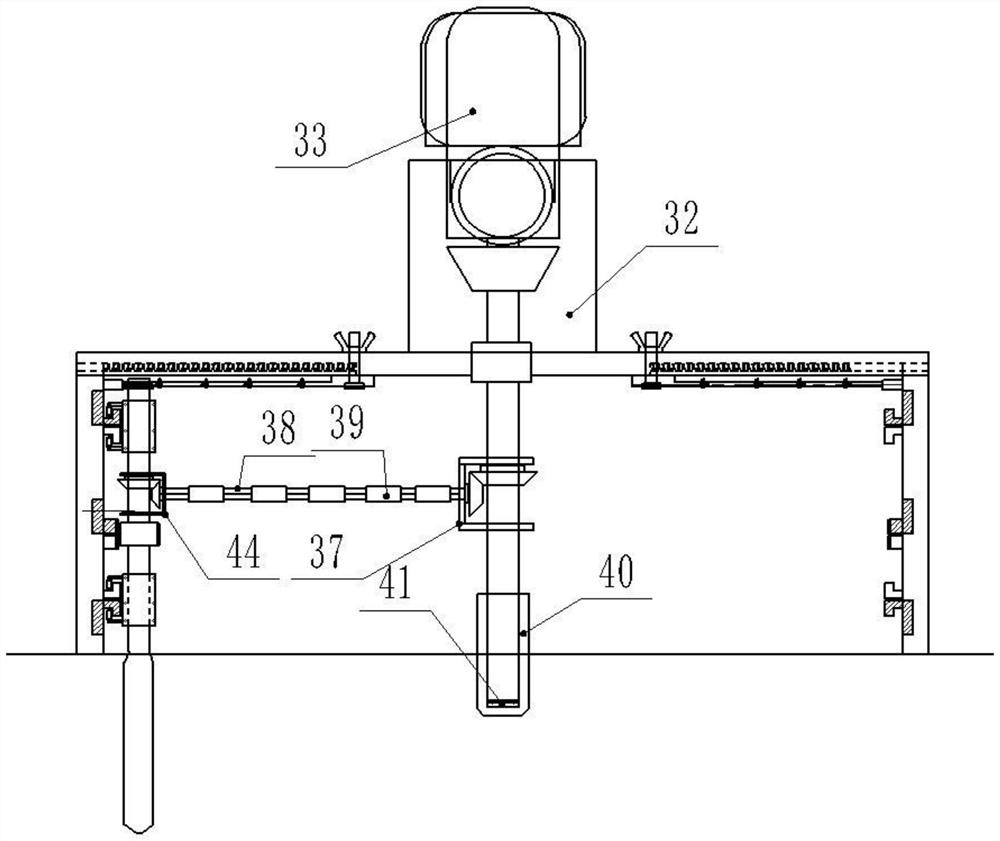

[0075] like Figure 1-14 As shown, in the method for opening square grooves on building walls or floors in the present invention, on the basis of the above-mentioned embodiments, a limit plate 32 is provided on the side of the center positioning shaft 4 installed on the positioning roof frame 1, and the limit plate 32 is arranged on the side of the position limit The plate 32 is provided with a clamping opening 34 for clamping the electric drill 33 .

[0076] Hand drill 33 adopts attached Figure 13 As shown in the electric drill with a horizontal handle, when installing, the upper end of the center positioning shaft 4 is clamped on the hand electric drill 33, and the horizontal handle of the hand electric drill 33 is stuck in the clamping opening 34 of the limiting plate 32 to prevent the positioning of the top plate The position of rack 1 is offset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com