Involute spline spline tooth modification design method and processing method and gear product thereof

A technology of involute splines and involute external splines, which is applied in the field of gear manufacturing, can solve the problems of reduced axial fit length, reduced contact area, and reduced centering accuracy, so as to reduce eccentric loads, The effect of not generating chips and avoiding wear and tear failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

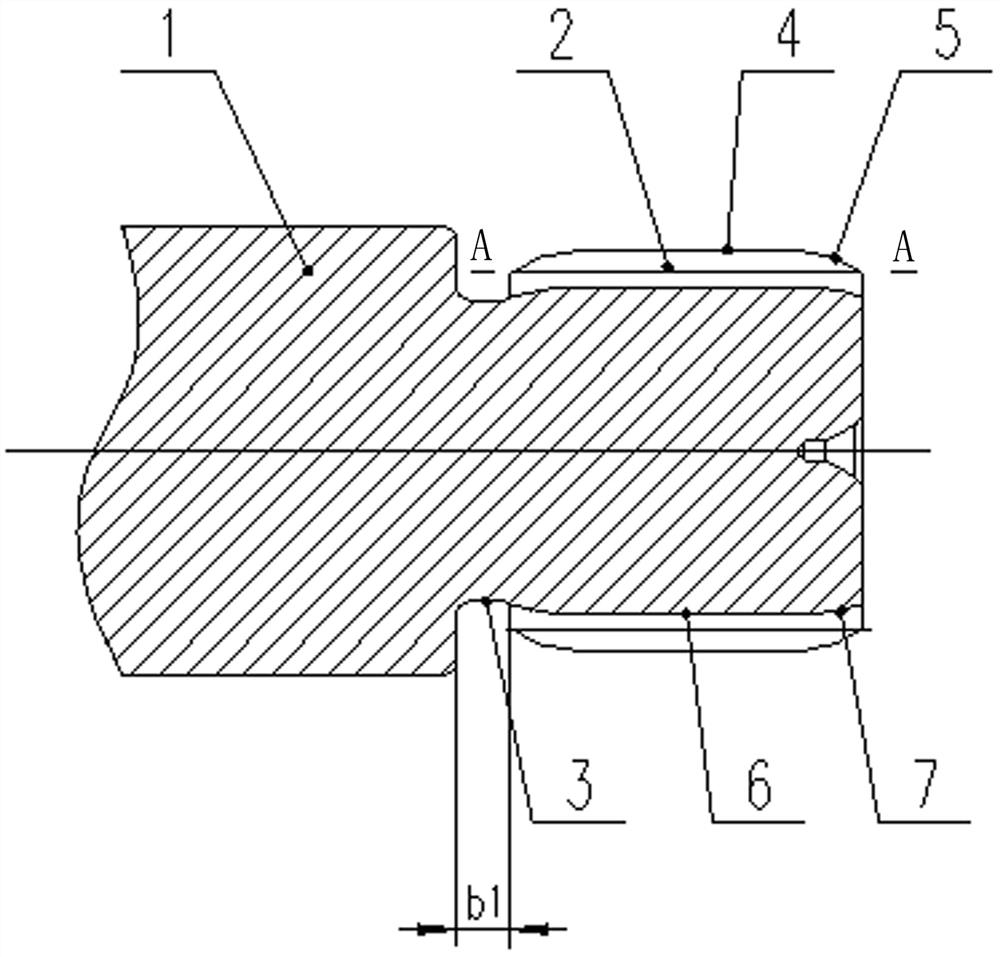

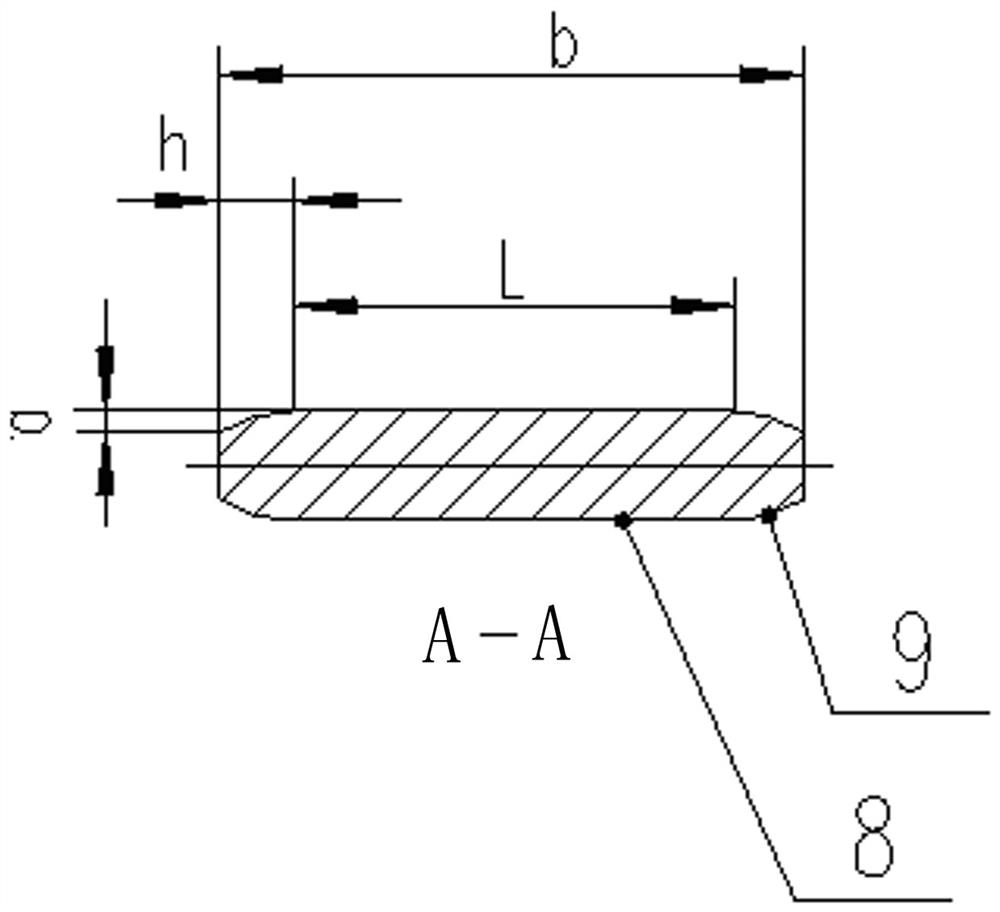

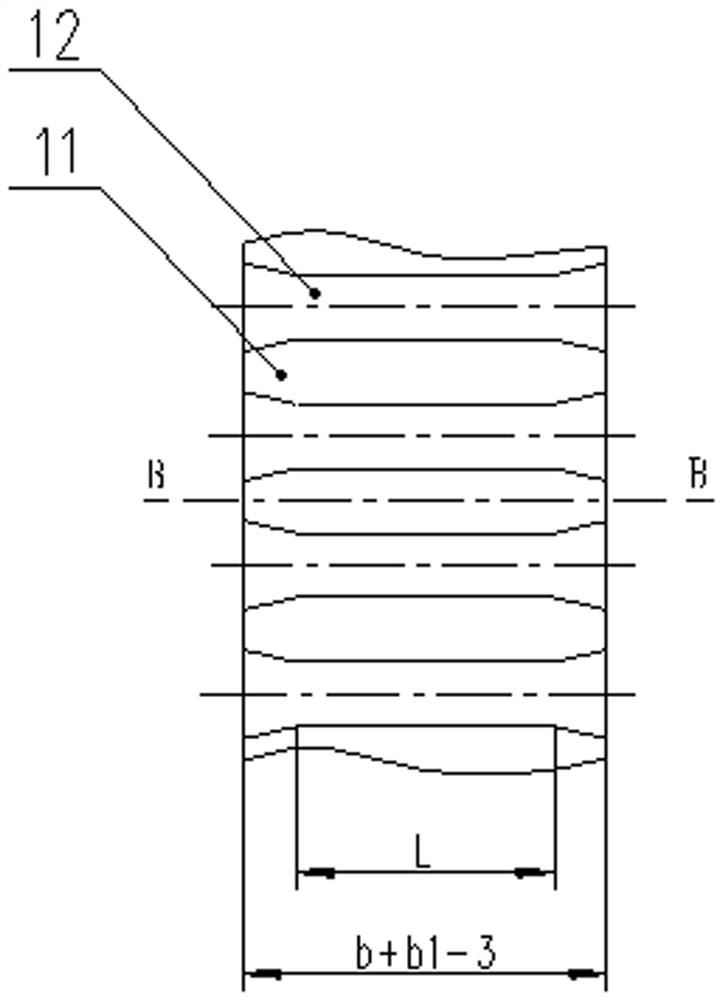

[0034] like figure 1 and figure 2 As shown in the figure, this embodiment discloses a method for modifying the shape of an involute spline spline tooth, which includes modifying the tooth direction of the tooth surface of the two key teeth of the key tooth, the tooth top and the tooth root at both ends; The tooth surfaces of the key teeth are in contact with each other at the middle section of the key tooth, and no modification processing is performed; the length L of the middle section of the key tooth without modification processing is calculated according to the formula 2T10 for the bearing capacity of the involute spline. 3 / LΨZHD≤[σp], where T is the transmitted torque; L is the working length of the key; Ψ is the uneven load distribution coefficient; Z is the number of key teeth; H is the working height of the key tooth flank; D is the average diameter; [σp] is the allowable extrusion stress of spline connection.

[0035] Specifically, the tooth direction modification...

Embodiment 2

[0039] The present embodiment discloses an involute spline modification processing method using the involute spline tooth modification design method of Embodiment 1, comprising the following steps:

[0040] S1. Gear rolling is adopted. First, according to the modification designed by the involute external spline, determine the tooth direction modification arc amount a*h of the tooth surface of the two key teeth of the key teeth, the tooth tip modification arc at both ends and the tooth root modification arc;

[0041] S2. Forming and dressing the grinding wheel for grinding the tooth groove of the spline rubbing cutter, including dressing the grinding wheel tooth profile angle and grinding wheel radius R, wherein the dressing grinding wheel tooth profile angle corresponds to the spline tooth profile angle;

[0042] S3. Use the trimmed grinding wheel to grind the rubbing cutter. By adjusting the grinding stroke length L, the straight line length of the middle of the tooth groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com