Patents

Literature

37results about How to "Avoid wear failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

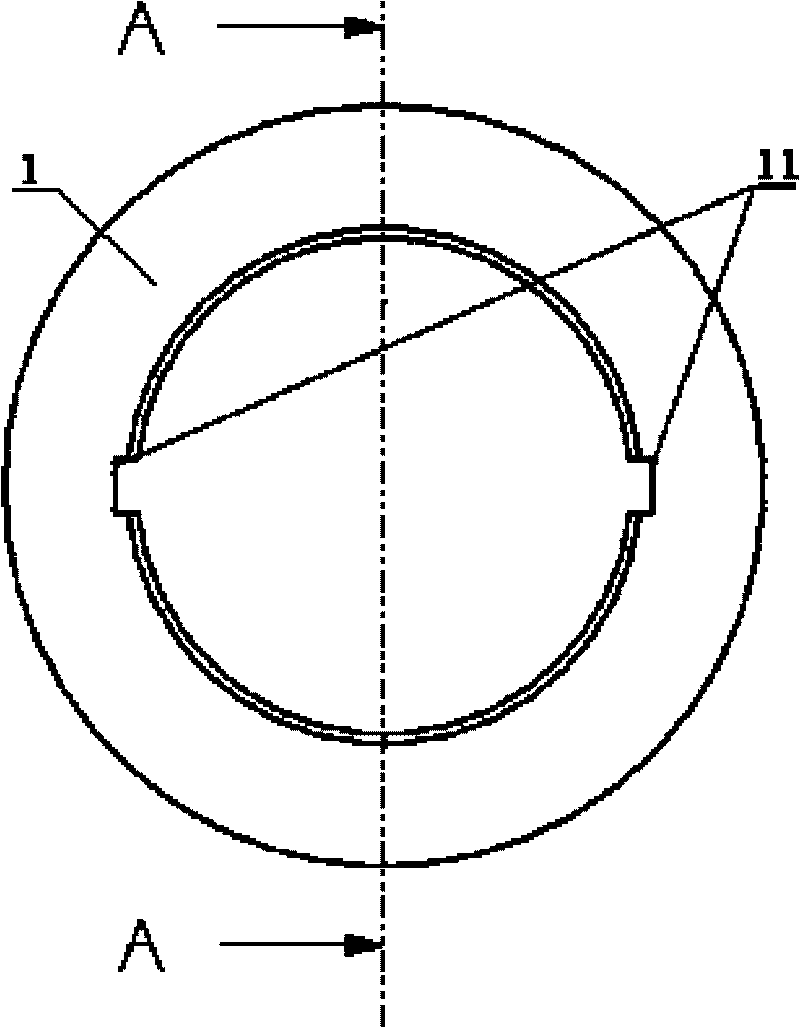

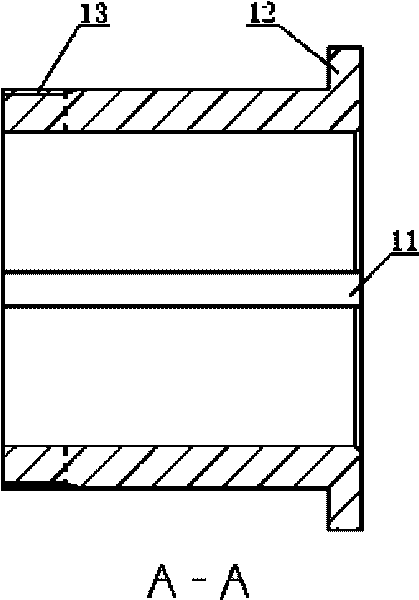

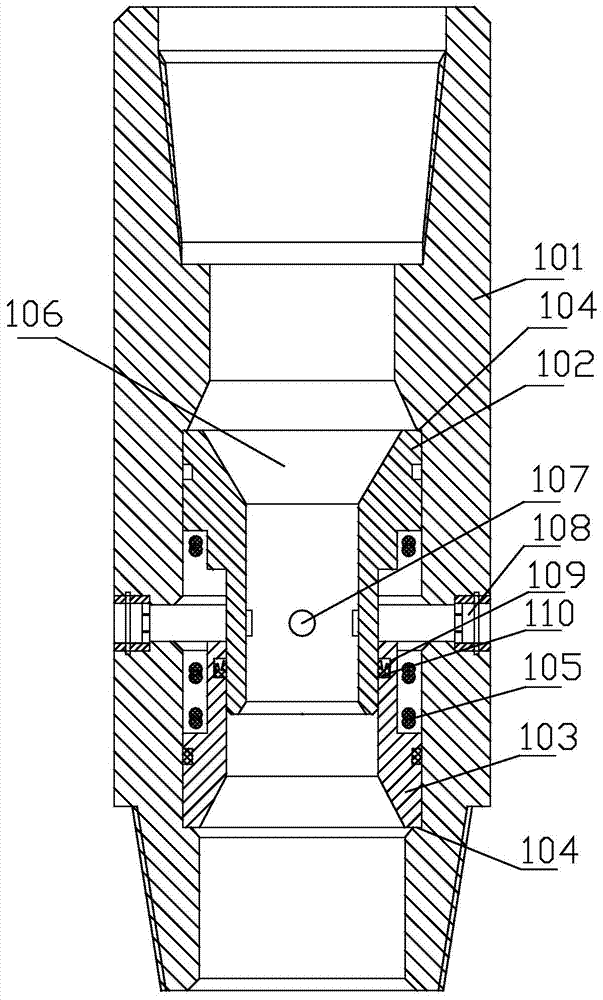

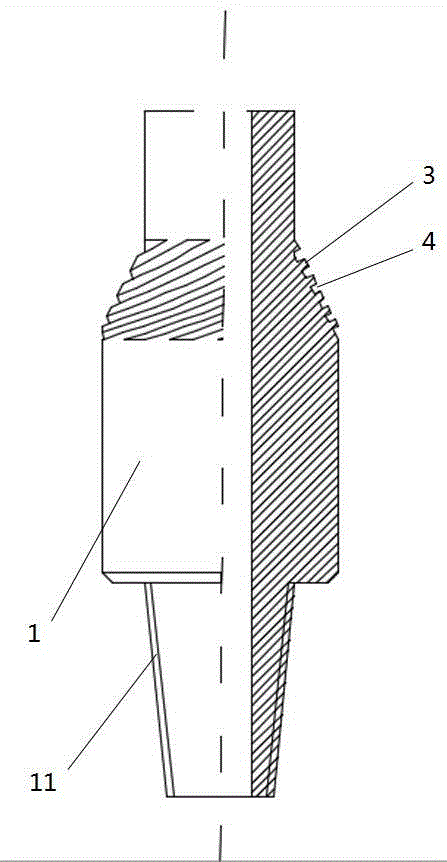

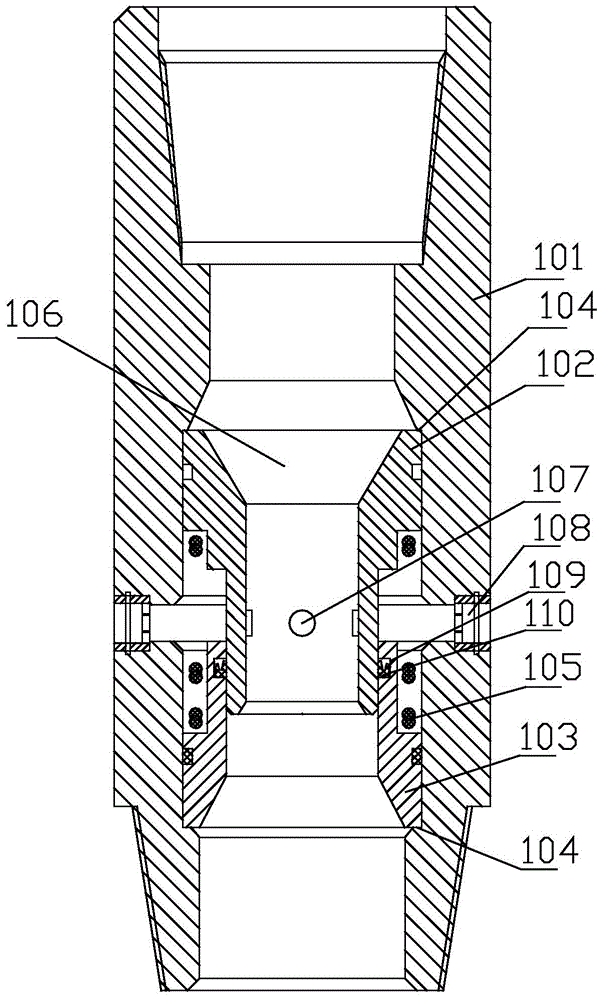

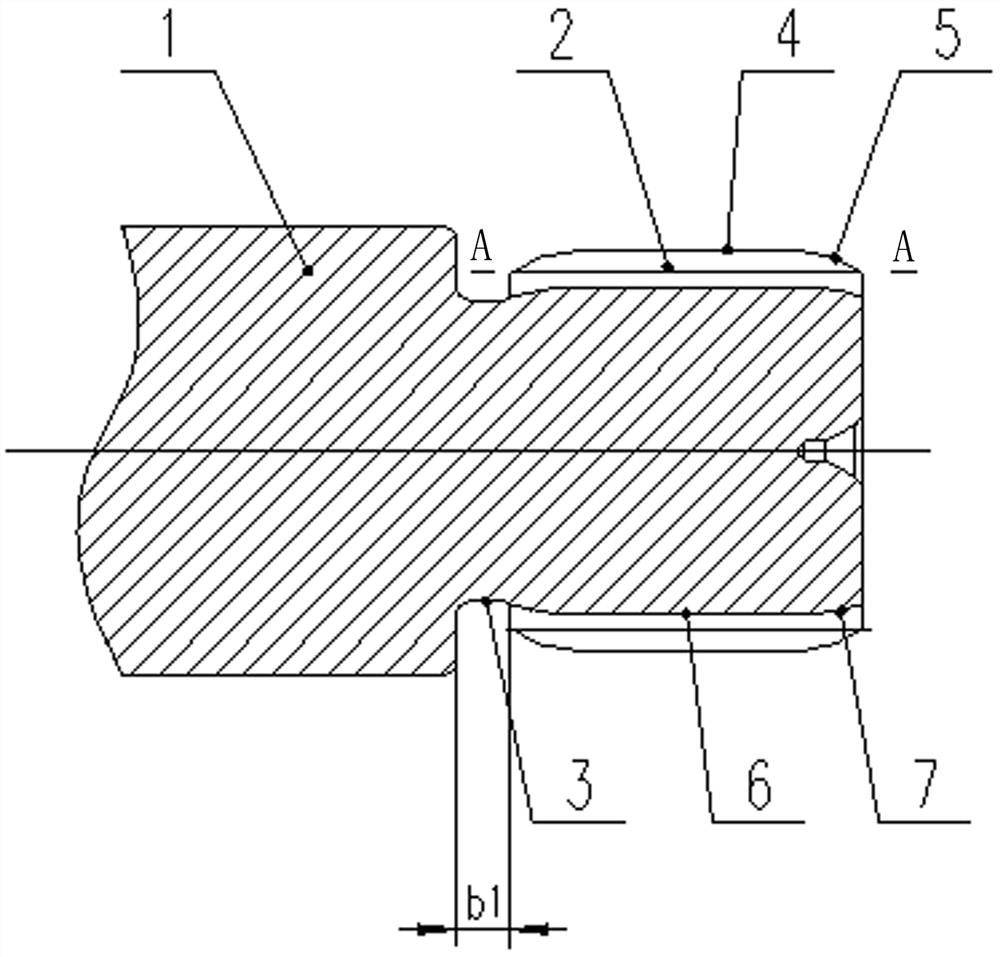

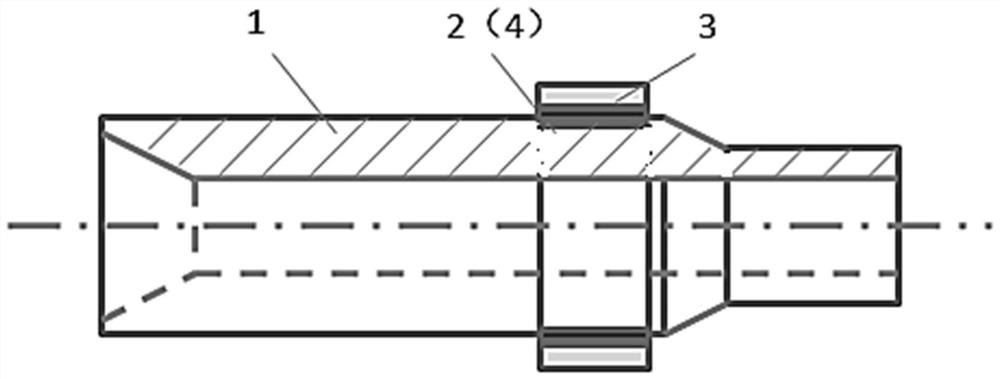

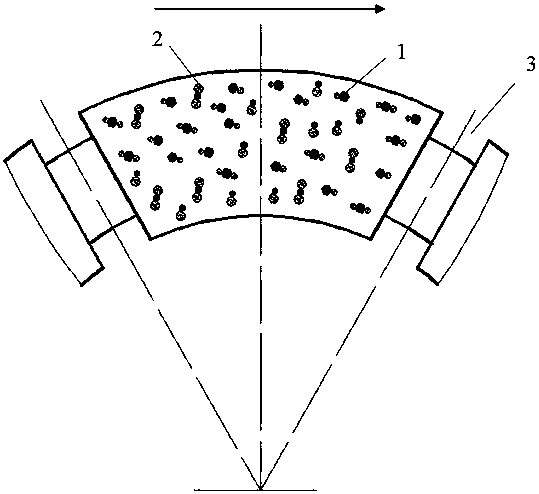

Dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid

ActiveCN101718297AImprove wear resistanceAccelerated corrosionBearing componentsSliding contact bearingsWater basedCarrying capacity

The invention discloses a dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid, which comprises a bearing sleeve, wherein a flange is arranged at one end of the bearing sleeve, and external threads are arranged at the other end of the bearing sleeve; a ceramic shaft sleeve is assembled at the outer layer of the bearing sleeve; a ceramic shaft bushing which comprises a special liquid cavity and a liquid hole structure is arranged outside the ceramic shaft sleeve; a shaft bushing sleeve with the special liquid cavity and the liquid hole structure is assembled at the outer layer of the ceramic shaft bushing; and the bearing of the invention also comprises a bearing end cover, wherein a ceramic ring is assembled at the inner end of the bearing end cover, and internal threads matched with the external threads of the bearing sleeve are arranged on the inner ring of the bearing end cover. The bearing of the invention can improve the wear resistance and the corrosion resistance, can operate in the poor water condition where sandy solid particles are contained, can be lubricated by the water-based lubricating liquid formed by adding other additives into water or water-based liquid; at the same time, the bearing has larger carrying capacity and rigidity, and can ensure a safe and stable operating state, thereby greatly prolonging the operation life.

Owner:TIANJIN UNIV

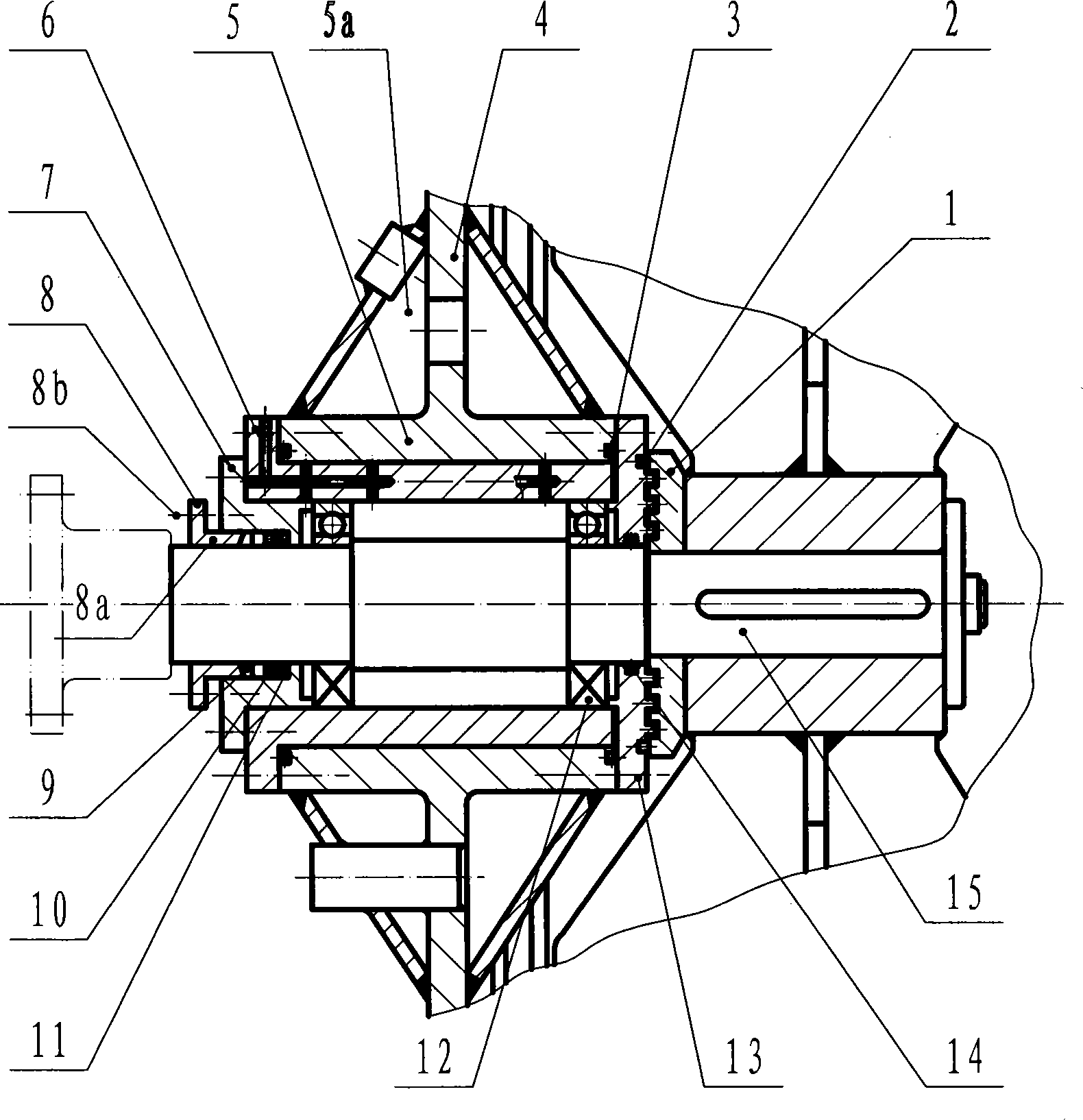

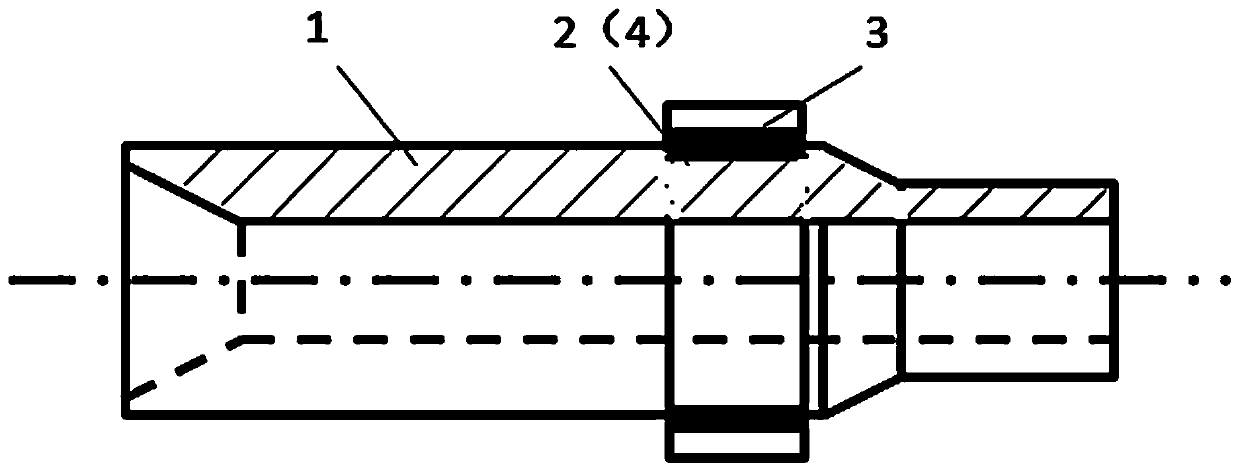

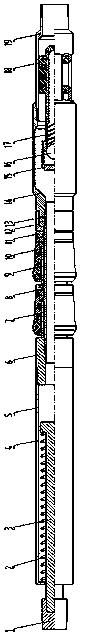

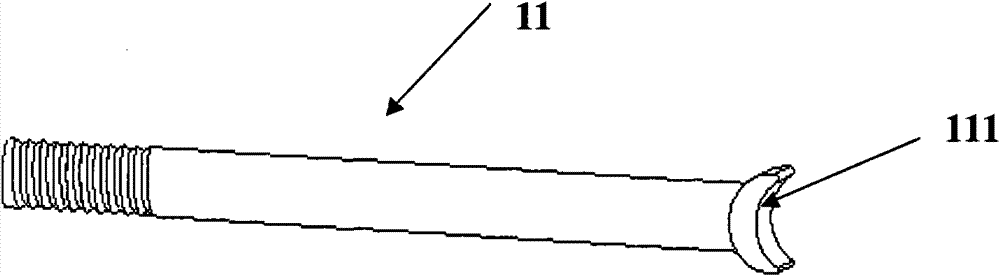

Efficient positive displacement motor drill under well

An efficient positive displacement motor under a well comprises a bypass valve assembly, a falling prevention joint, a motor joint, a universal joint assembly and a bearing joint assembly. The efficient positive displacement motor under the well is simple in structure, convenient to use, stable in operation under the well, safe, reliable, high in complete machine efficiency, capable of outputting larger torque, long in working time and service life, suitable for drilling needs of various complex wells at the present, free of piercing leakage and high in working reliability. A streamlined flow channel enables water conservancy losses of a main flow channel to be reduced, turn-off force is large, the defects of the interference effect and tooth form distortion of the conjugation curvature of a traditional single-screw machine type positive displacement motor are overcome, a universal shaft operates flexibly, energy efficiency is high, the universal shaft can work in the environments where no sand grain exists, and drilling fluid erosion exists, the service life is long, and mechanism strength is high.

Owner:QINGDAO JINJIANGYUAN IND EQUIP CO LTD

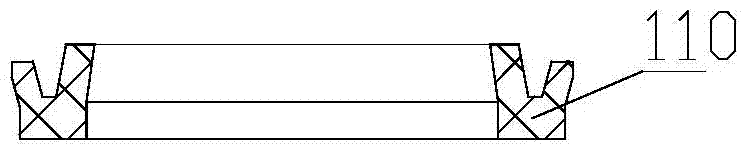

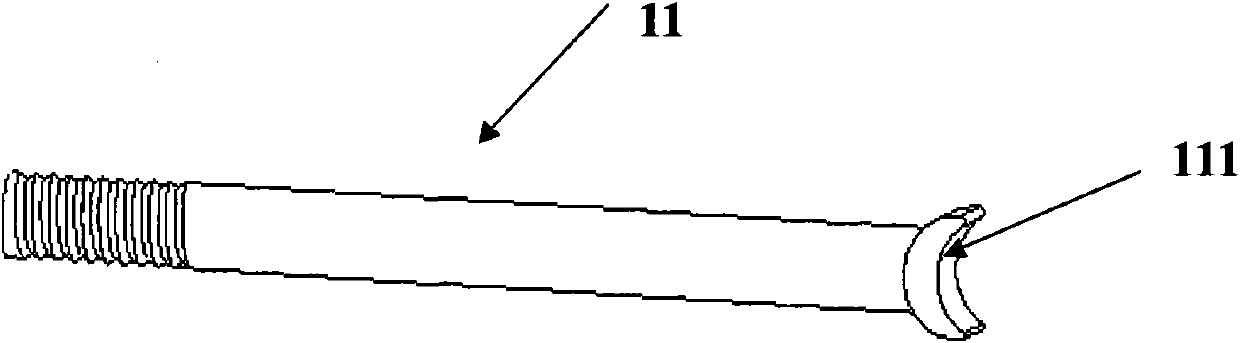

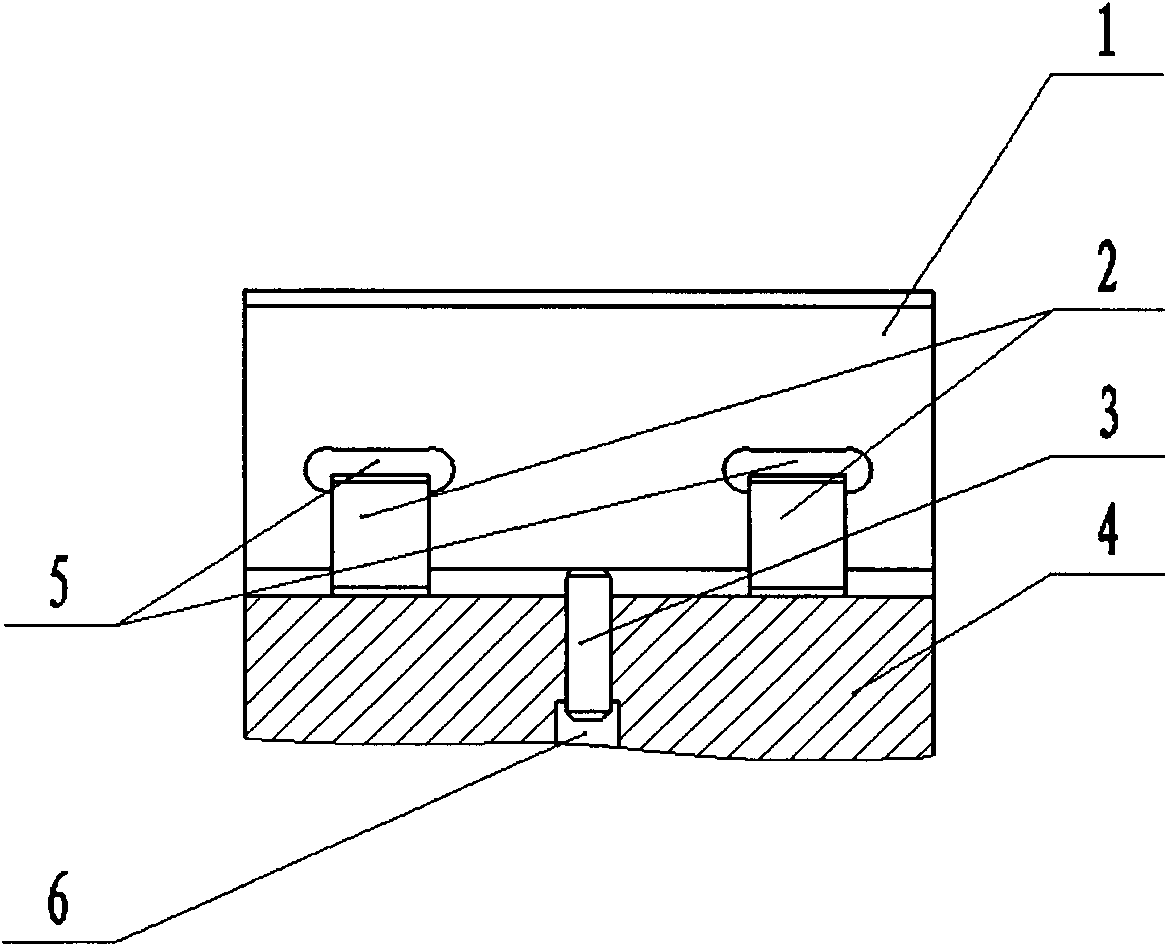

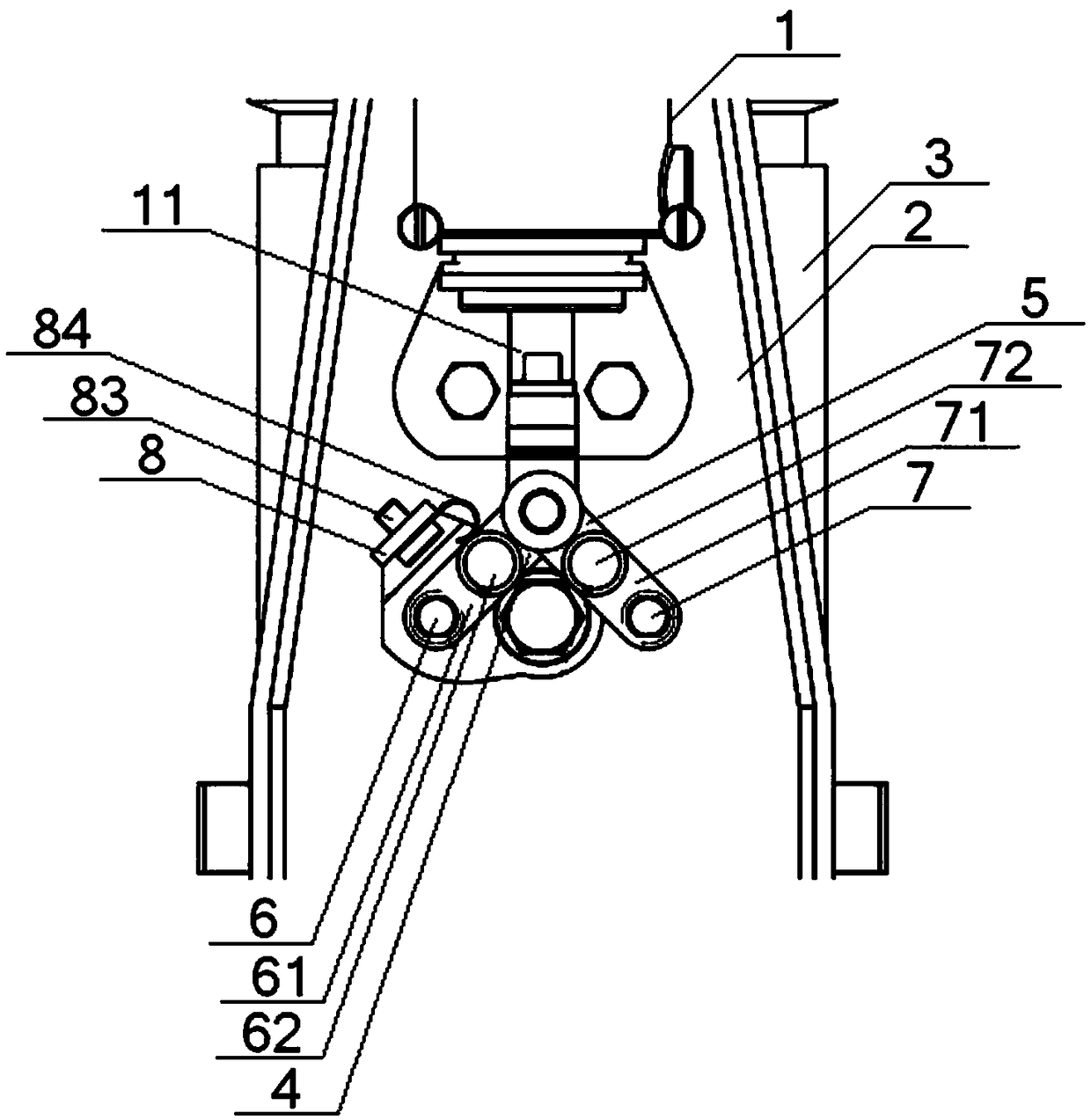

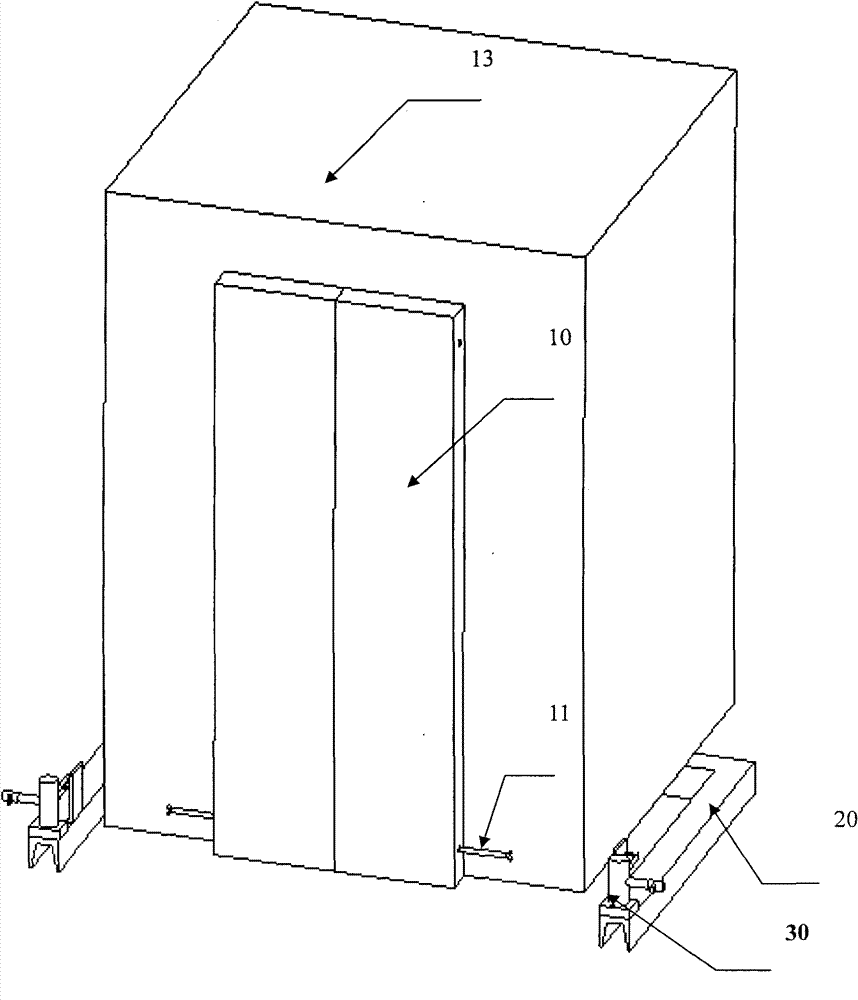

Protection device for abnormal movement during lift car leveling opening

The invention discloses a protection device for abnormal movement during lift car leveling opening, which can prevent a lift car from moving when a lift car door is in an open mode. The protection device of the invention comprises control devices, action protection devices, bearing devices, a supporting part, an electric protection device and a warning device, wherein the control devices are fixed at the bottoms of two sides of the lift car door; the action protection devices are fixedly installed at the heads of two sides of the supporting part, and the middle part of the supporting part is connected with the bottom of the lift car; each bearing device is arranged in each leveling position in the shaft wall, and is matched with the corresponding action protection device; each action protection device is driven by the corresponding control device to reciprocate; when the lift car door is completely opened, the control devices drive the action protection devices to be embedded into thebearing devices, and keep the balance of the whole lift car when the lift car generates a movement trend; the electric protection device cuts off the electric circuit of a lift when the lift car is in the process of opening; and the warning device actuates a warning circuit when the lift car generates a gliding trend, and warns to prevent the use of the lift in an abnormal state.

Owner:HITACHI ELEVATOR CHINA

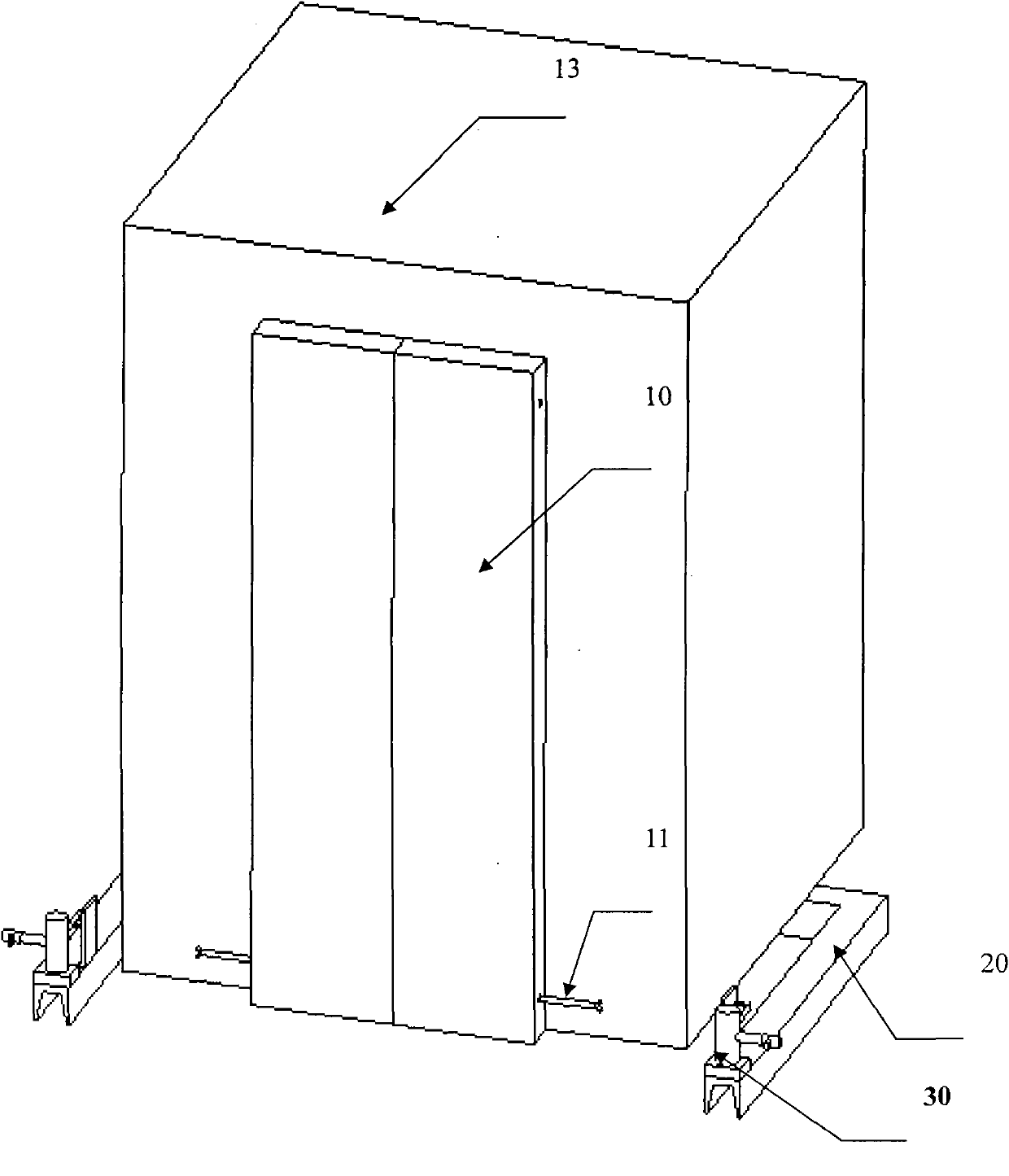

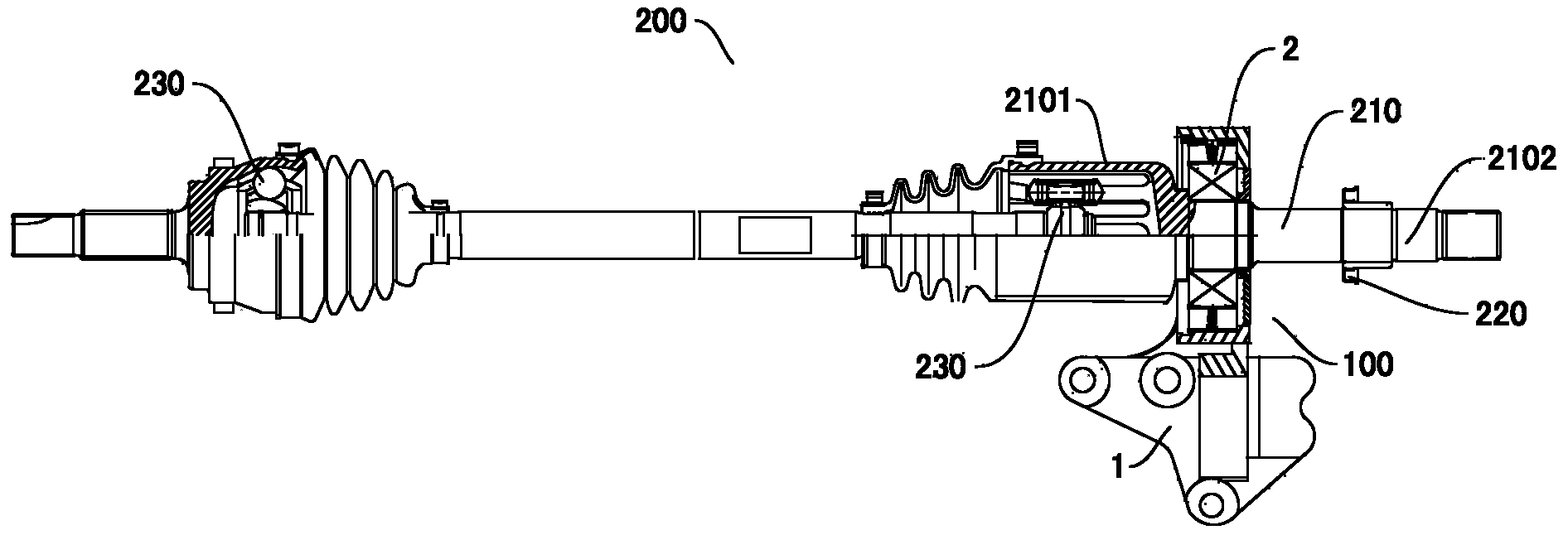

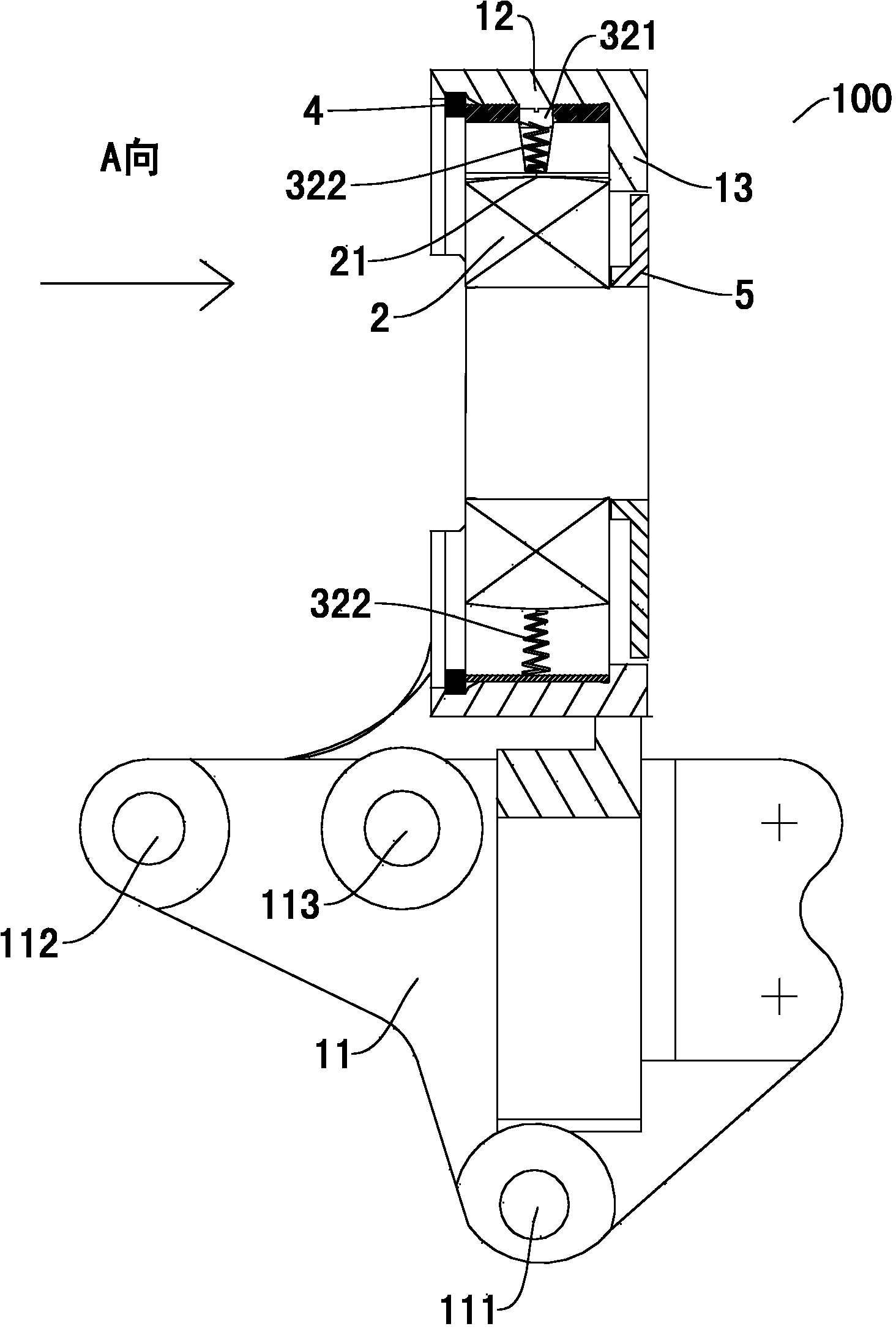

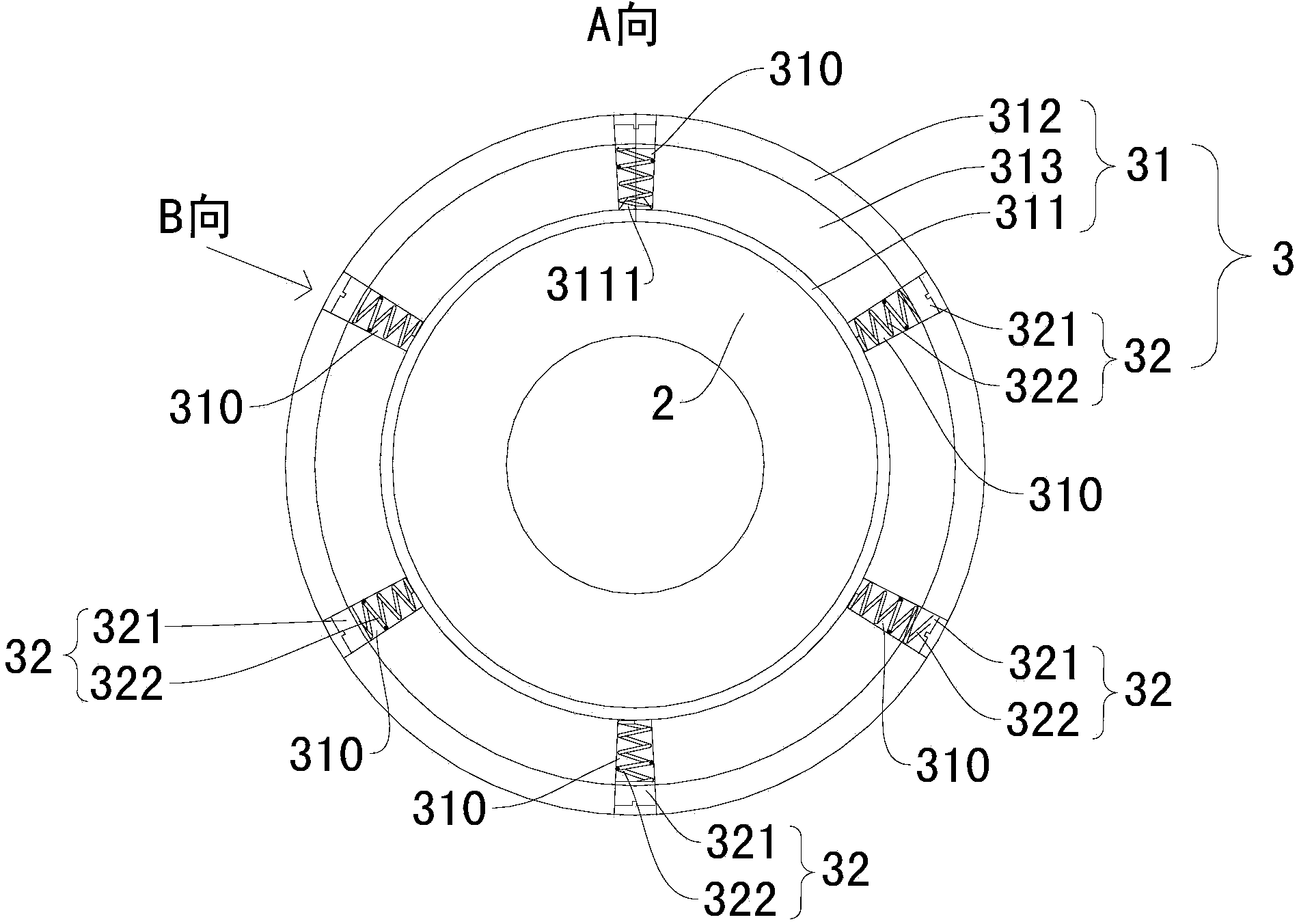

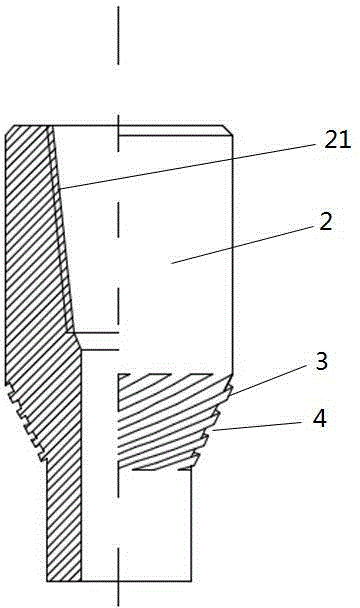

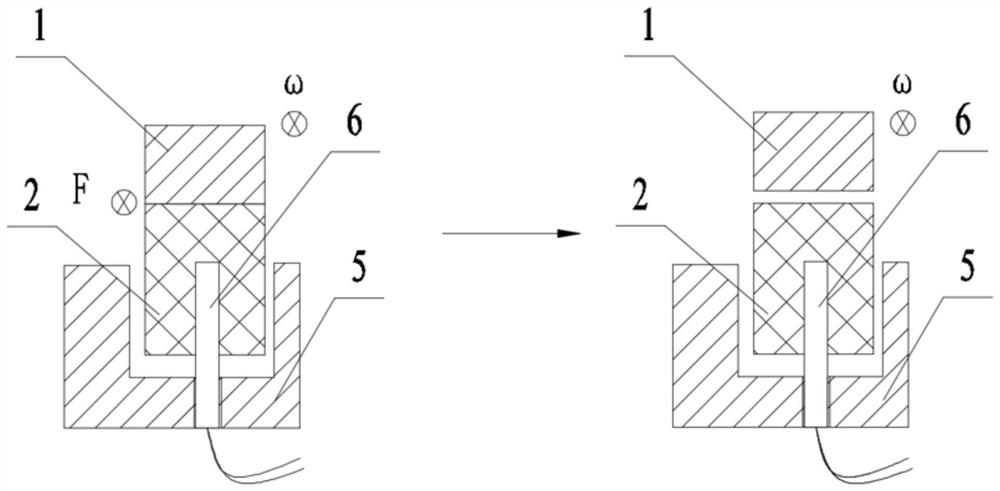

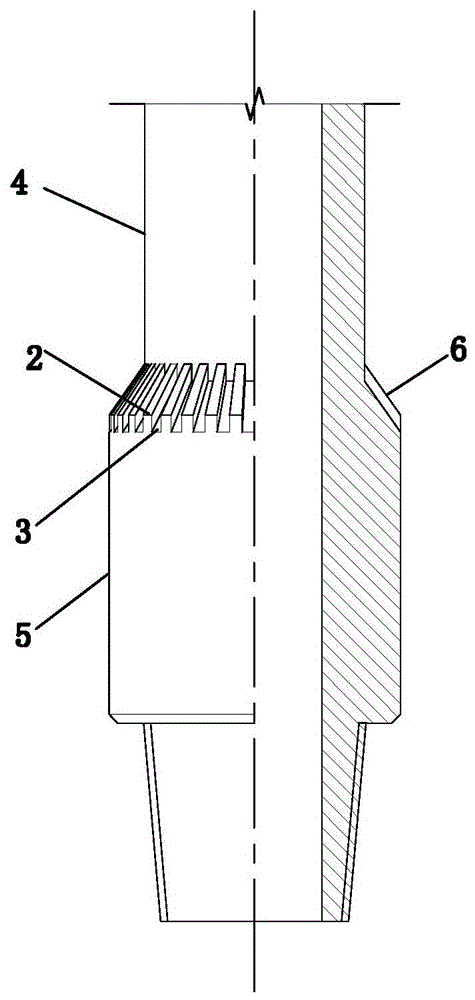

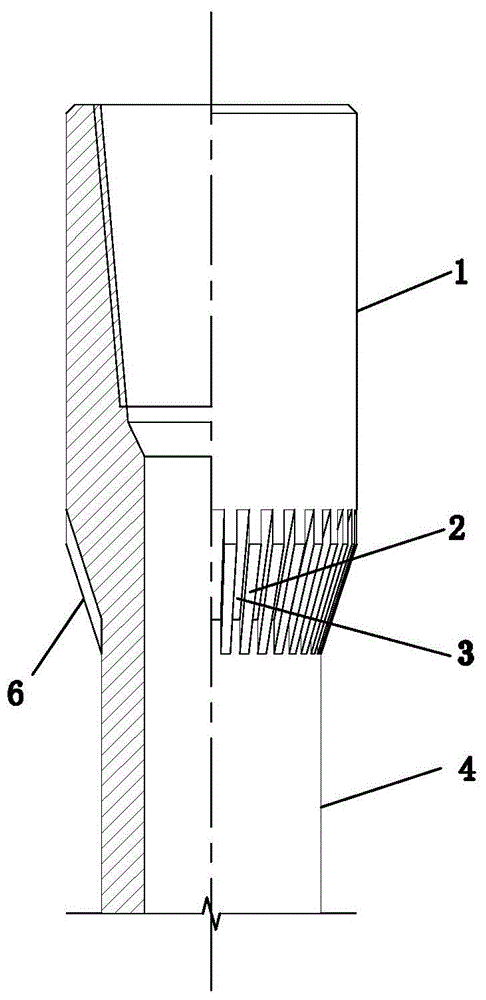

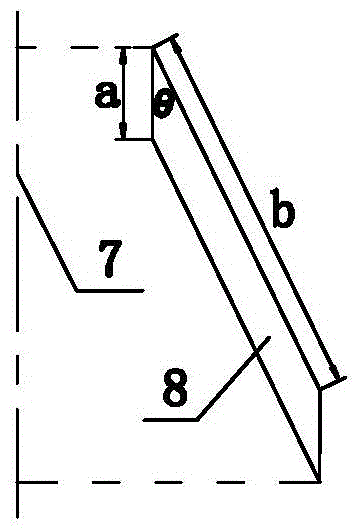

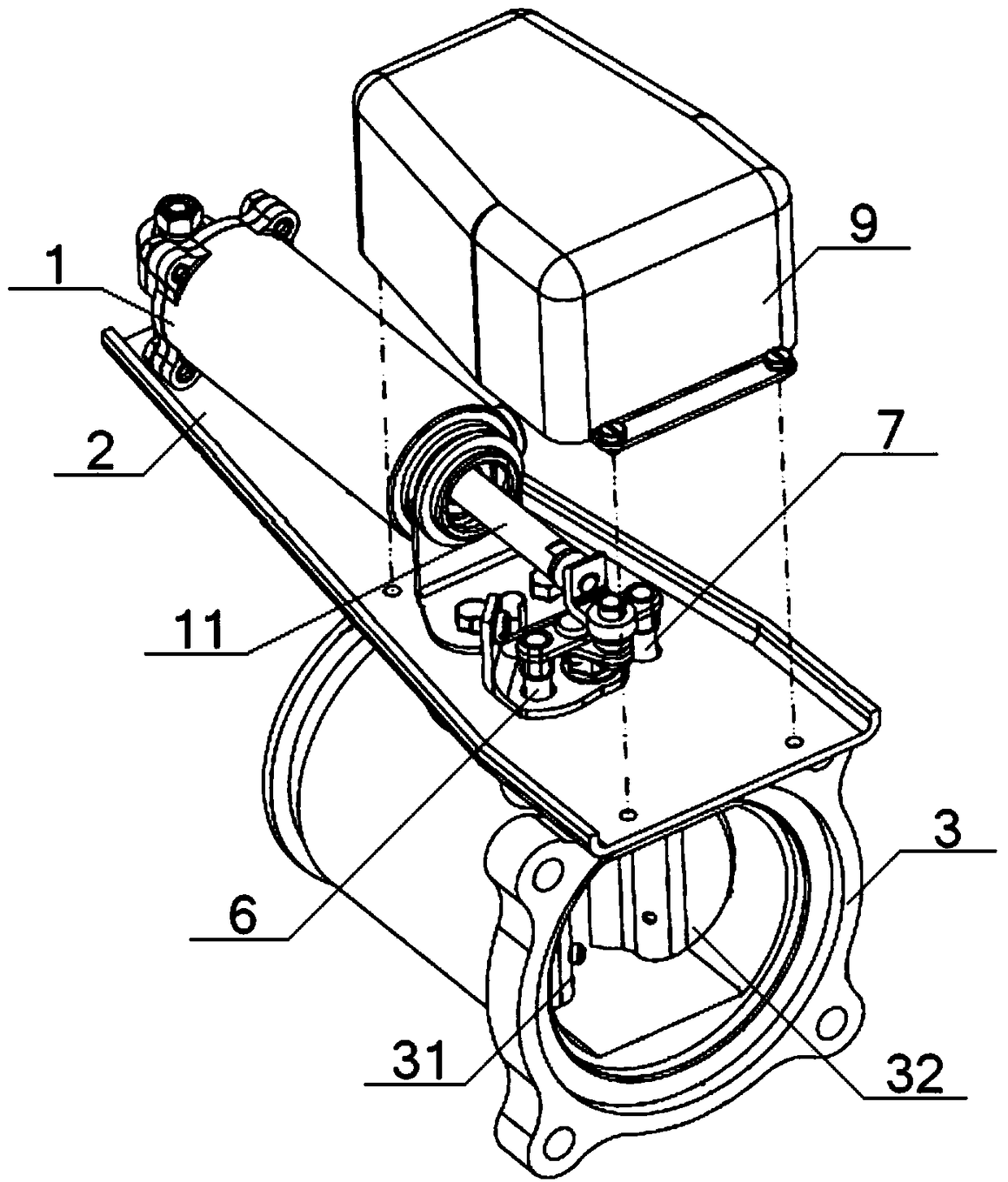

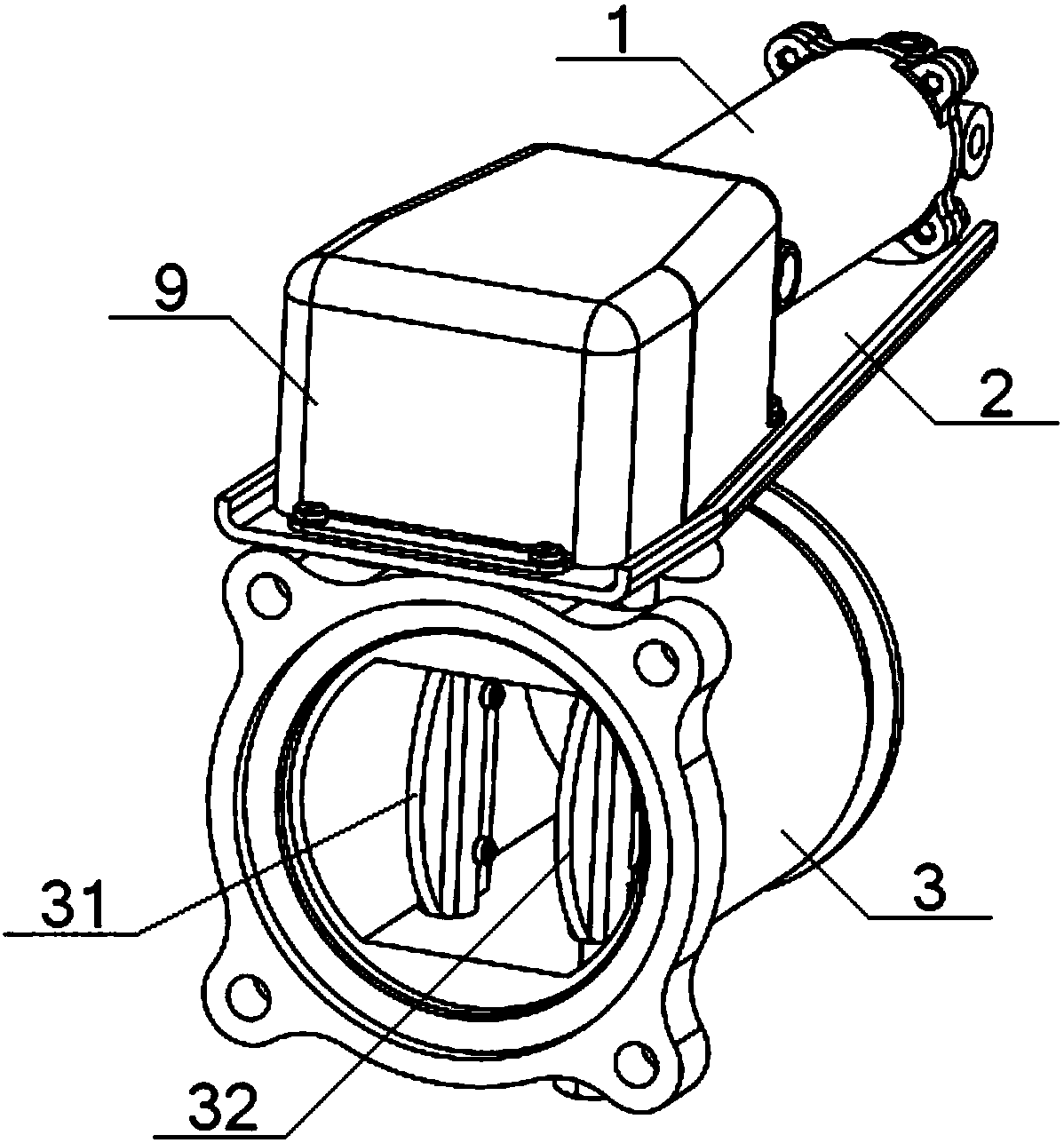

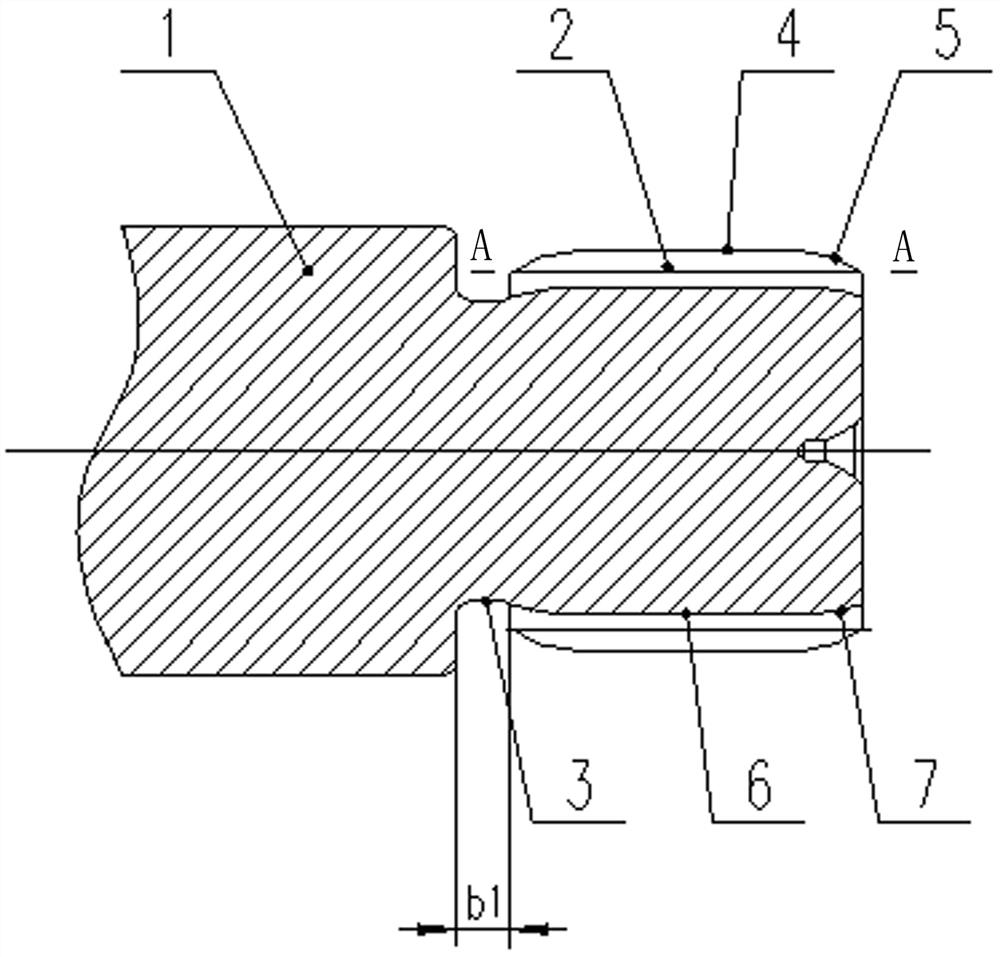

Middle supporting assembly used for vehicle driving shaft assembly

ActiveCN103832210AAvoid wear failureSimple structureRolling contact bearingsAxle unitsDrive shaftVehicle driving

The invention discloses a middle supporting assembly used for a vehicle driving shaft assembly. The middle supporting assembly used for the vehicle driving shaft assembly comprises a support and a bearing, wherein the support is fixed on an engine of a vehicle; the bearing is arranged on the support, a driving shaft of the vehicle is supported by the bearing, and the peripheral surface of the bearing forms a spherical surface. According to the middle supporting assembly used for the vehicle driving shaft assembly, the peripheral surface of the bearing is designed into the spherical surface, the central axis of the bearing and the central axis of the output end of a transmission of the vehicle are coaxial after the driving shaft assembly is arranged on the vehicle, and therefore the problem that an oil seal of the transmission and an oil seal of the bearing are abraded and lose efficacy is effectively resolved, and the service life of the bearing and the service life of the transmission are prolonged.

Owner:GREAT WALL MOTOR CO LTD

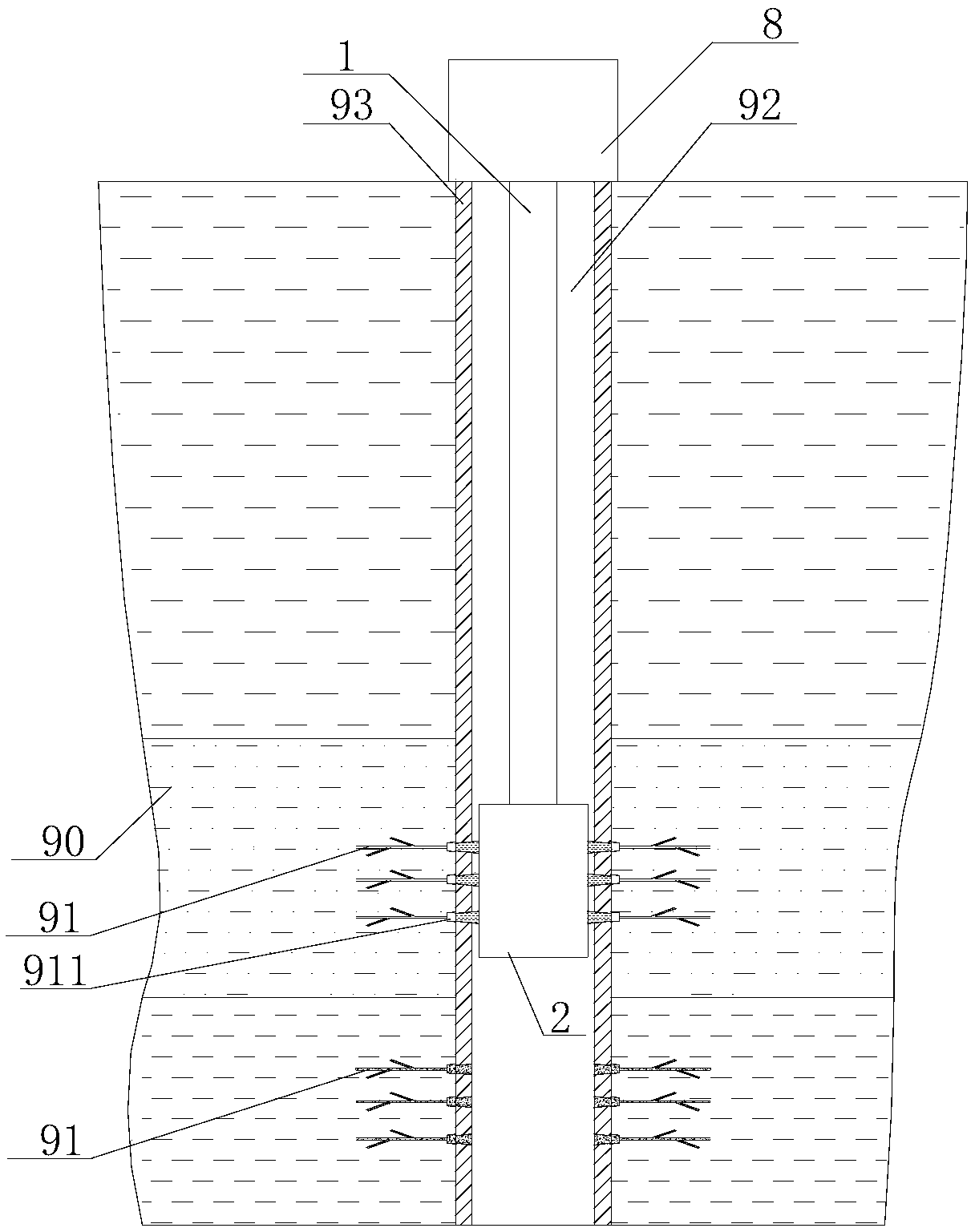

Hydraulic jet sectional temporary plugging infinite stage fracturing method

The invention relates to a hydraulic jet sectional temporary plugging infinite stage fracturing method, which relates to the technical field of oil and gas exploitation. The method uses coiled tubingto lower a downhole tool to a predetermined position in a shaft, the reservoir at the predetermined position is subjected to hydraulic jet fracturing, and a formation fracture is formed; the positionsof the coiled tubing and the downhole tool are maintained, plugging fluid mixed with a temporary plugging agent is pumped from the wellhead, and directional temporary plugging is carried out on the formation fracture; and the coiled tubing is lifted to enable the downhole tool to reach multiple positions in need of fracturing in the shaft sequentially, the above hydraulic jet fracturing and directional formation fracture temporary plugging are repeated, and infinite fracturing in single string running is completed. The method can overcome the problems of wear failure of a packer after multiple times of use and failure of the formation fracturing at a casing slip sleeve in the existing infinite stage fracturing technology; and in combination of hydraulic jet fracturing and temporary fracture plugging, using of the packer to pack the formation is not needed, infinite fracturing in single string running is realized, and infinite stage fracturing for the reservoir is truly realized.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

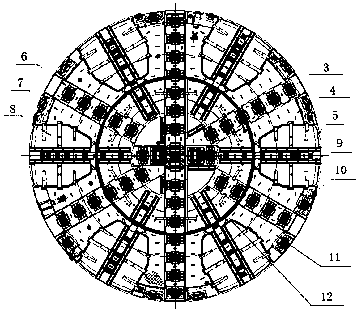

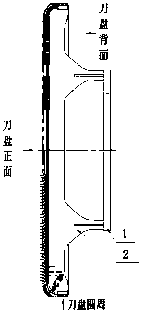

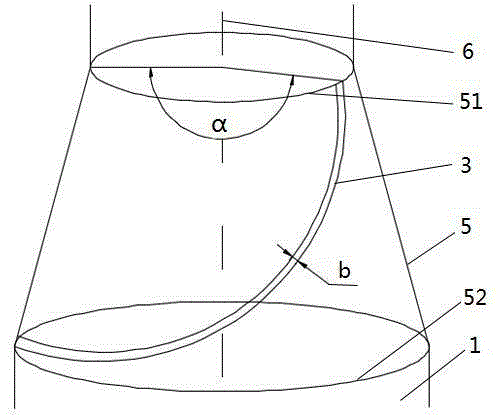

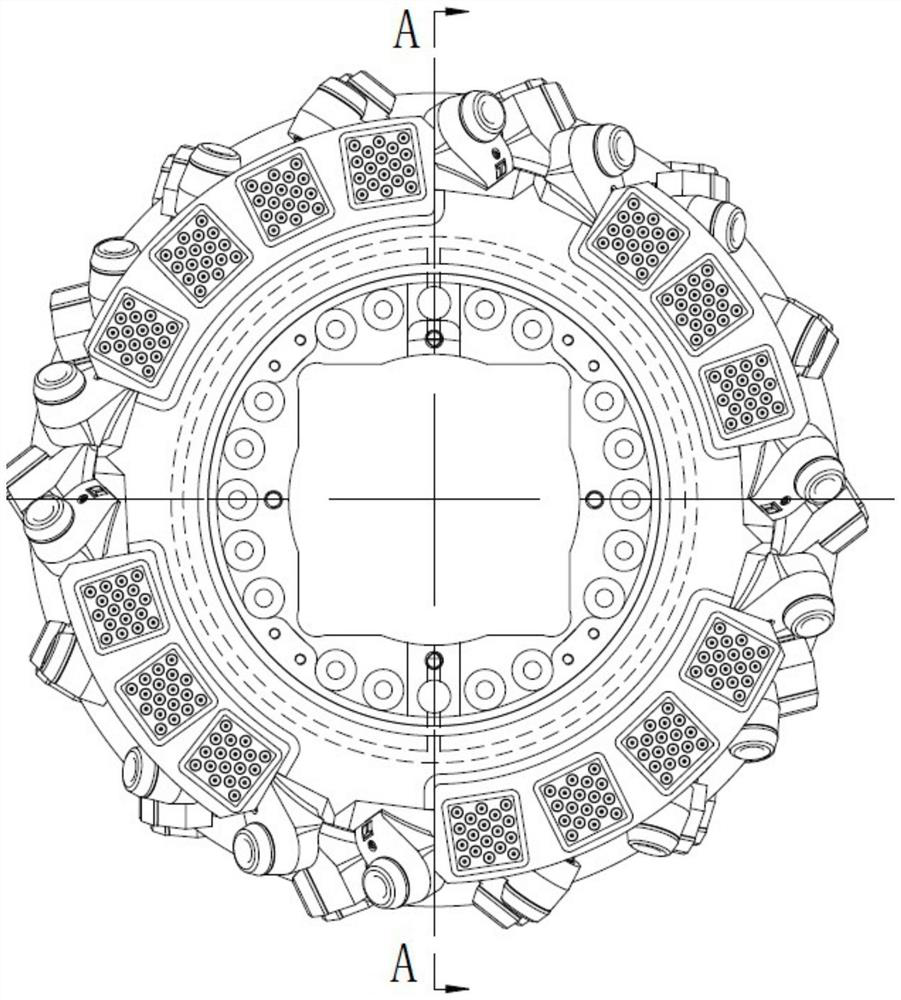

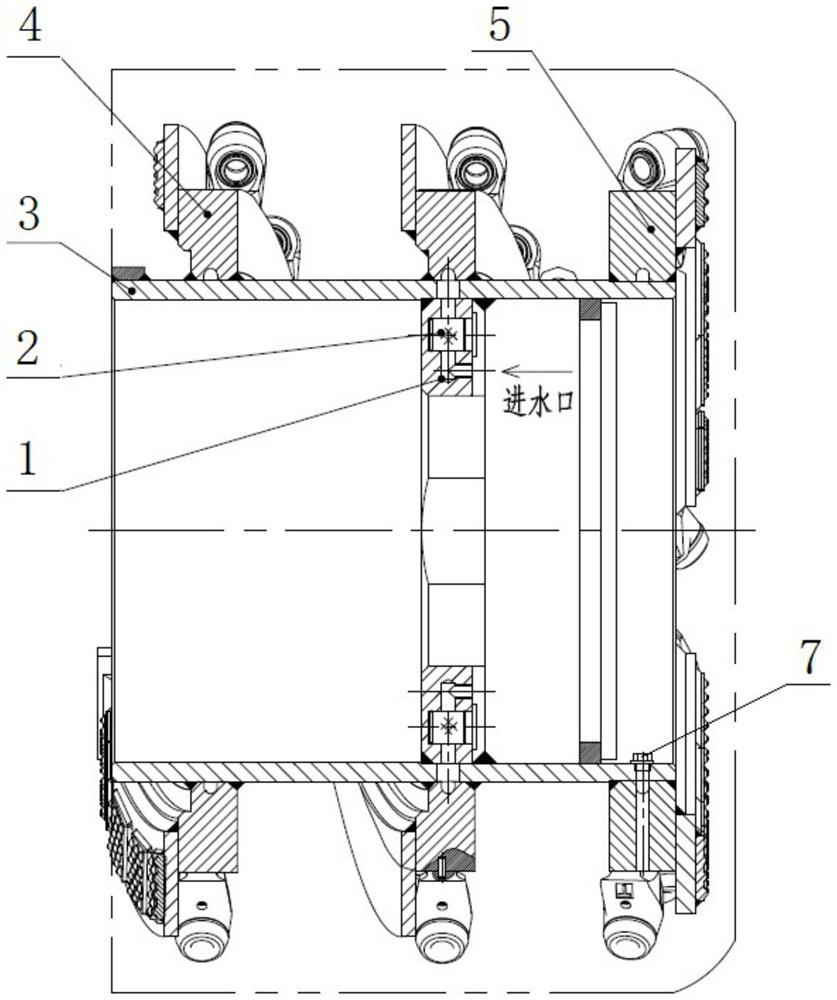

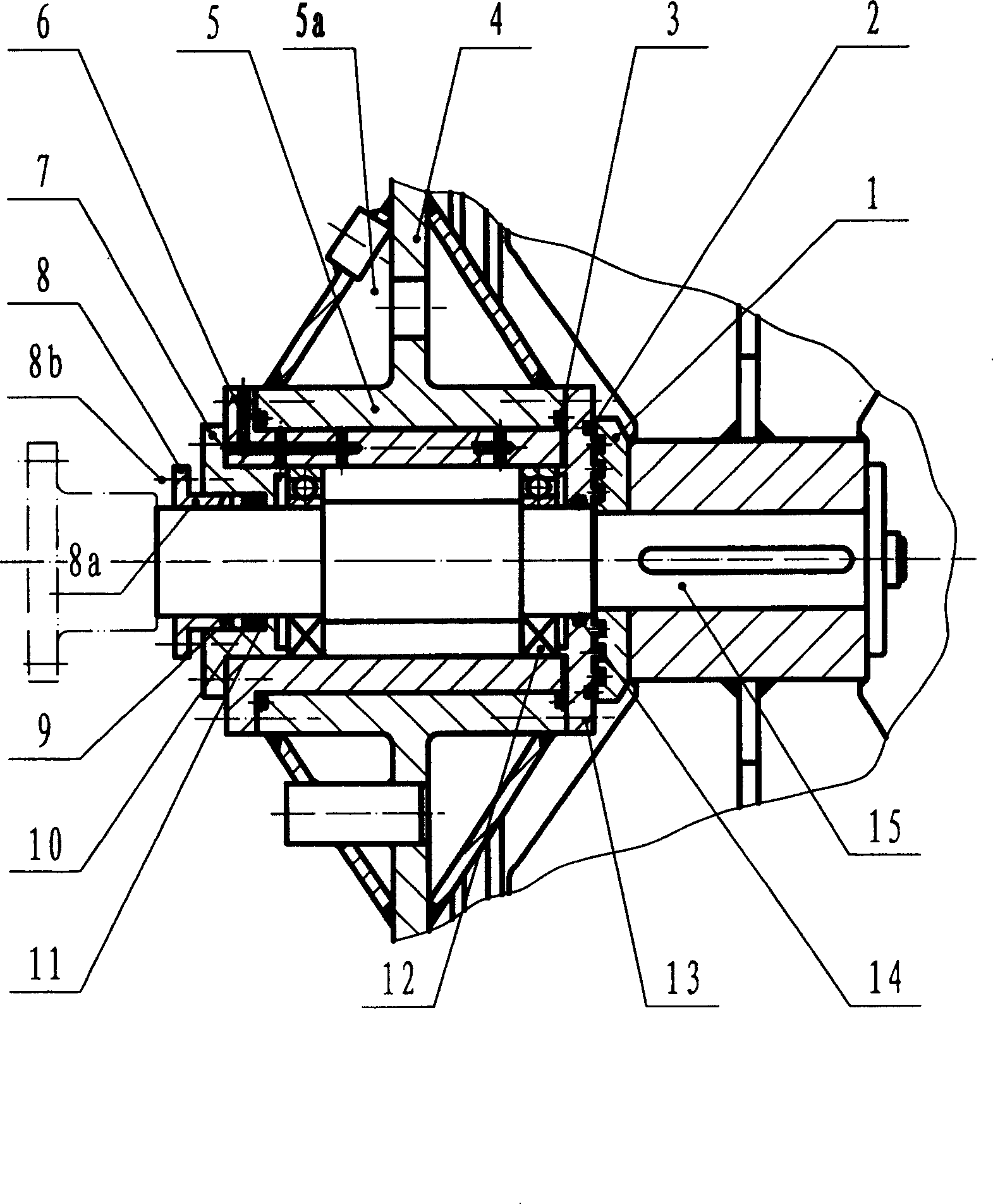

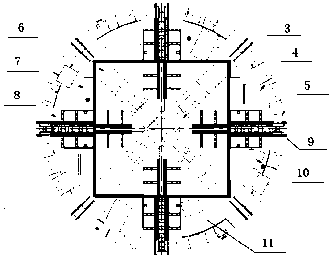

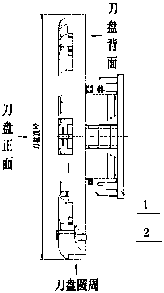

Major diameter soil-pressure balance shield machine full stratum cutter

The invention relates to a major diameter soil-pressure balance shield machine full stratum cutter comprises a cutter flange, a landing leg structure, a cutter center, a cutter periphery, a cutter outer ring, a cutter spoke, a cutter panel, and a opening area; the main structure of the cutter adopts a high strength steel plate; the front face of the cutter is connected to a wear-resisting composite steel plate in a paving and welded mode; the two faces of the composite steel plate are made of different materials, the wear-resisting side is chromium carbide steel plate and the other side has good welding performance to ensure the quality of the paving welding, and the position that cannot pave the wear-resisting composite steel plate surfacing is bead welded with a wear-resisting layer; twosteel pipes with diameters being 25mm are laid on the surface of the front face of the cutter in the cutter diameter direction in a cross mode; hydraulic oil is filled in the steel pipes and the steel pipes are connected to a hydraulic circuit; whether the cutter is worn or not is judged by the pressure change of the hydraulic circuit; the wear-resisting property of the cutter is improved by using the major diameter soil-pressure balance shield machine full stratum cutter, and the service life is prolonged; and wear pattern of a tool and the cutter can be monitored in real time, the tool canbe replaced timely to prevent the tool form wearing, and the major diameter soil-pressure balance shield machine full stratum cutter is suitable for shield full stratum geological condition.

Owner:辽宁三三工业有限公司

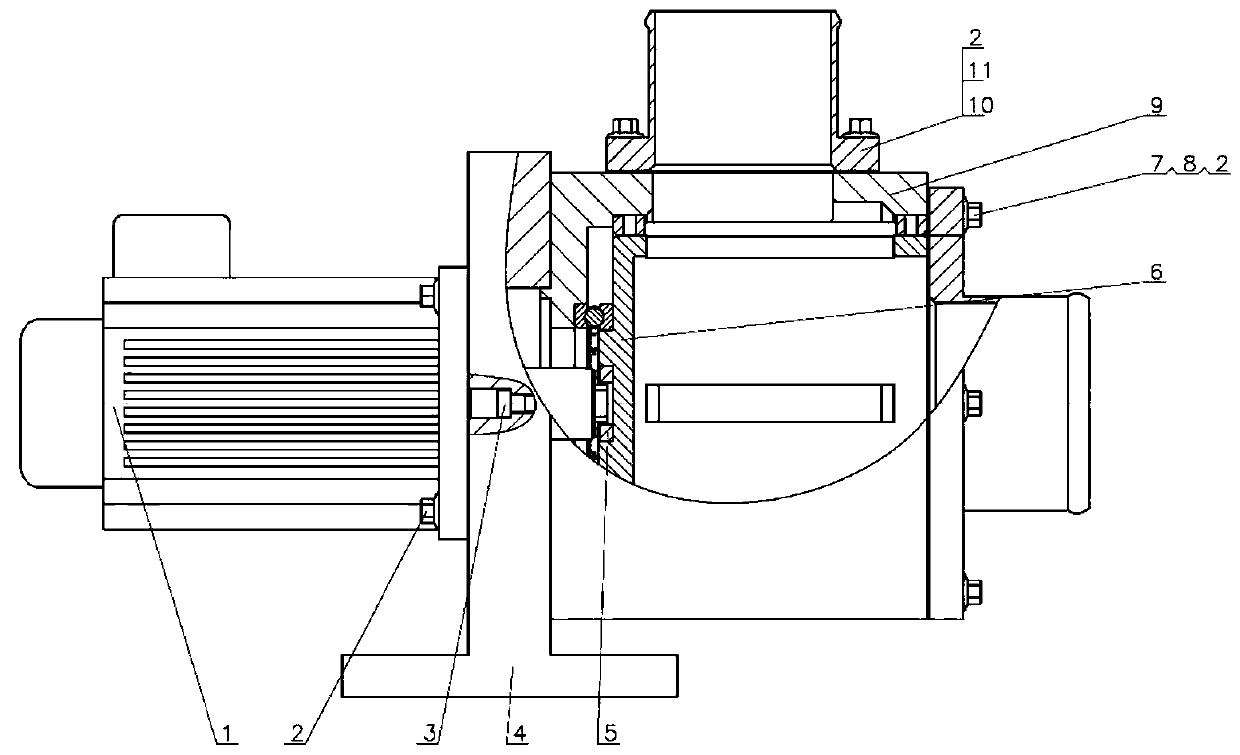

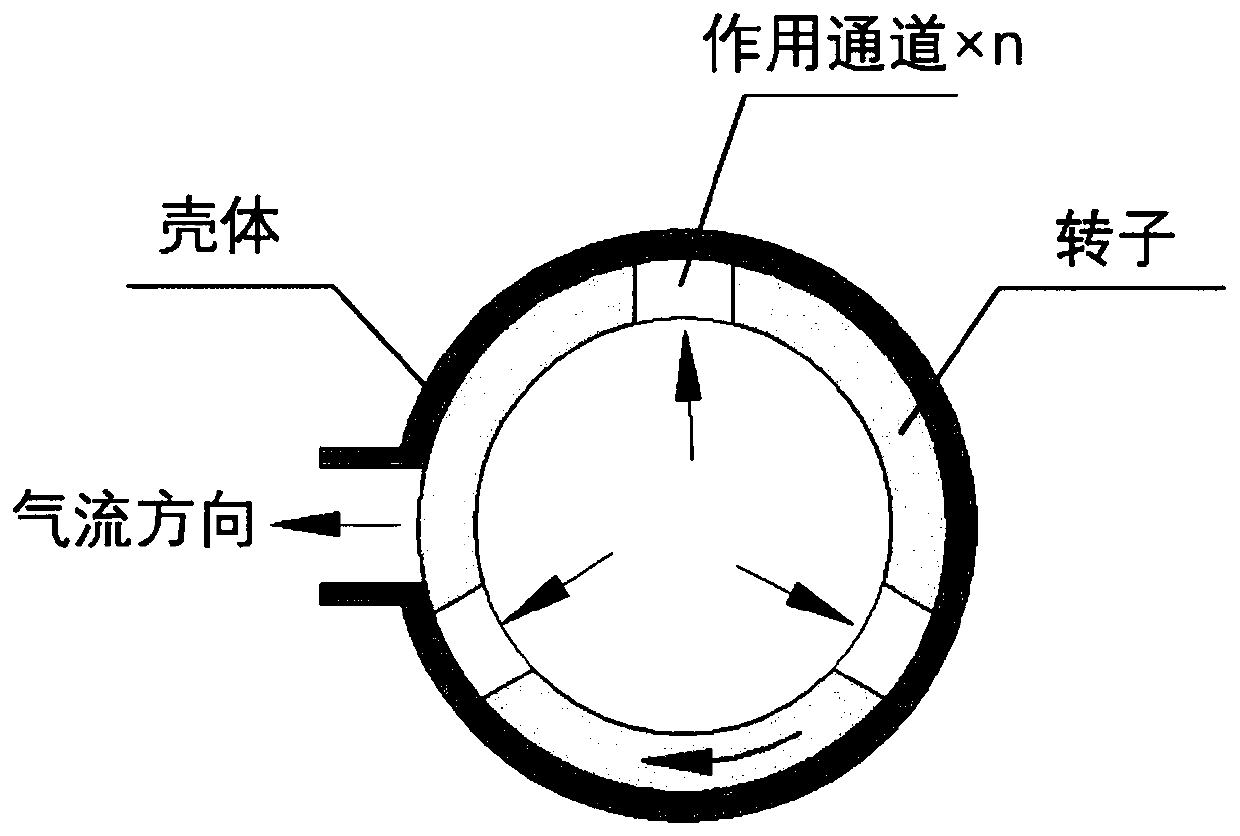

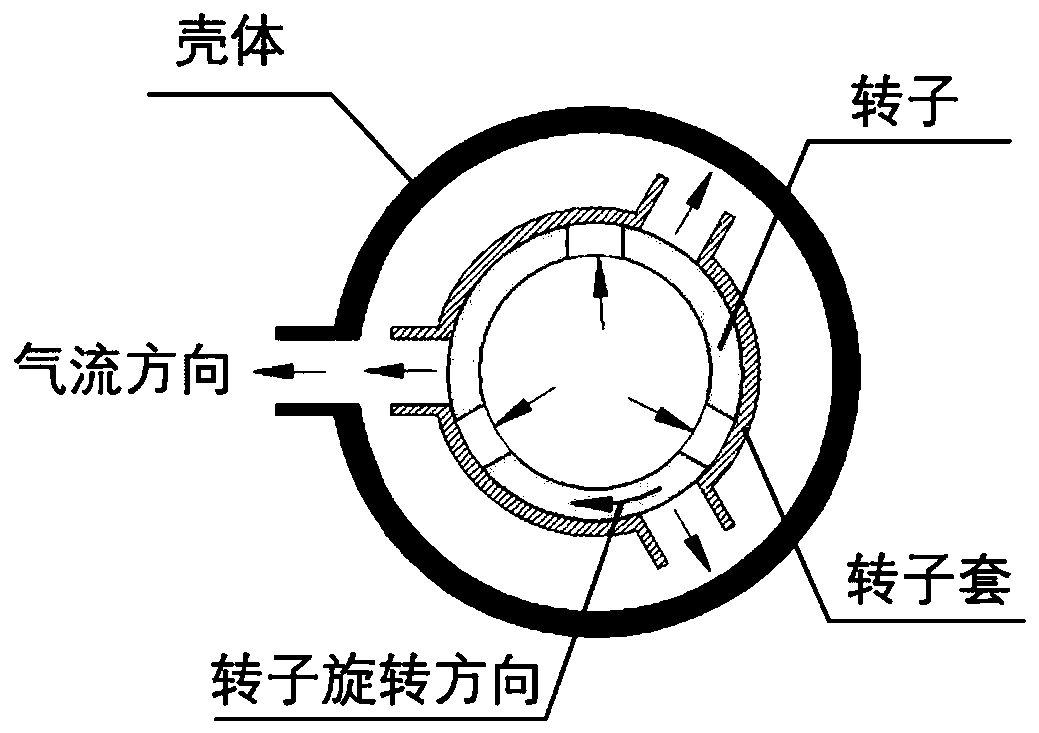

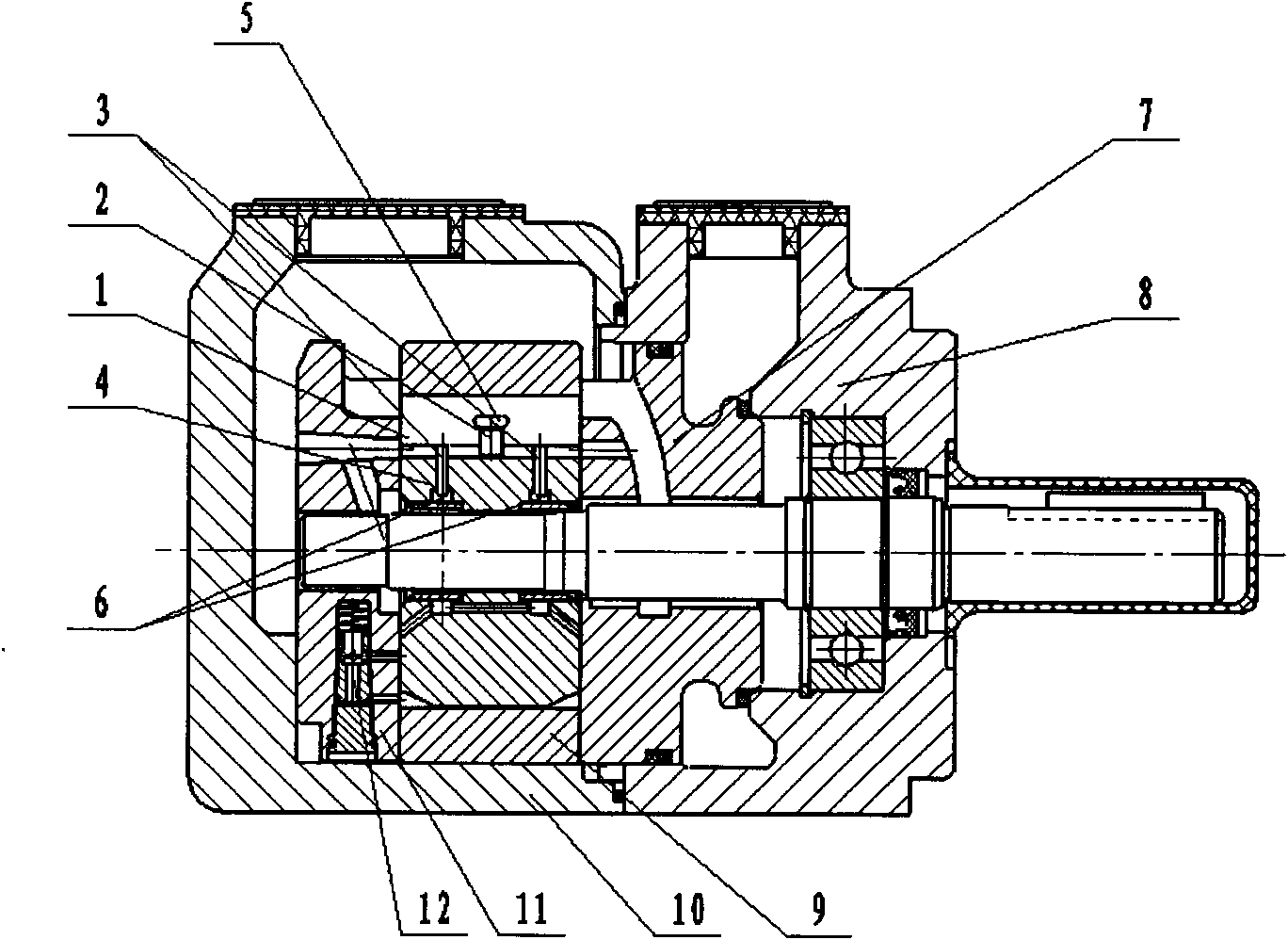

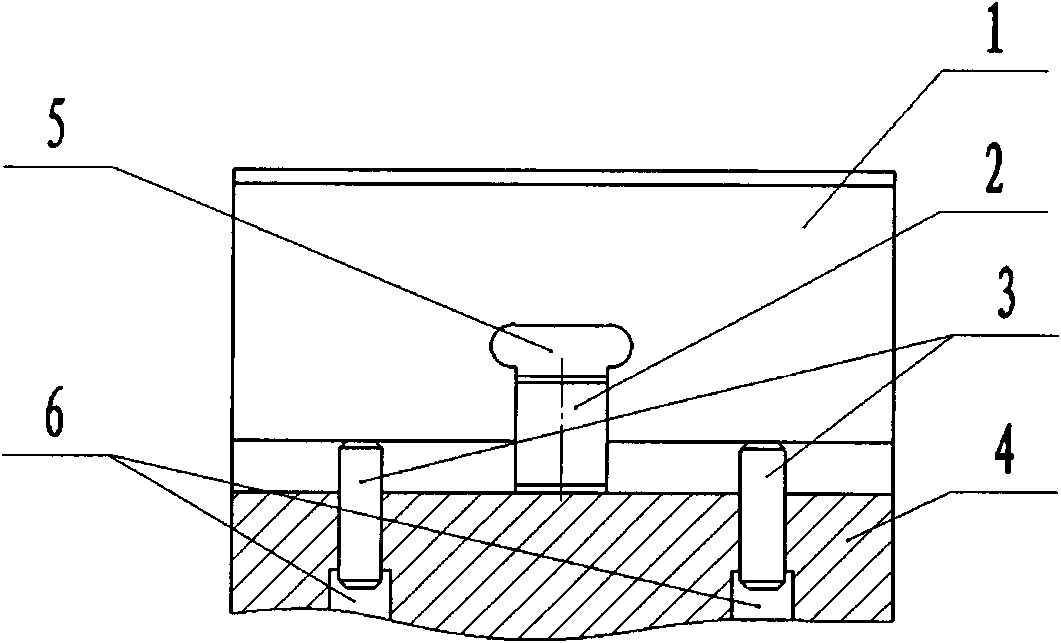

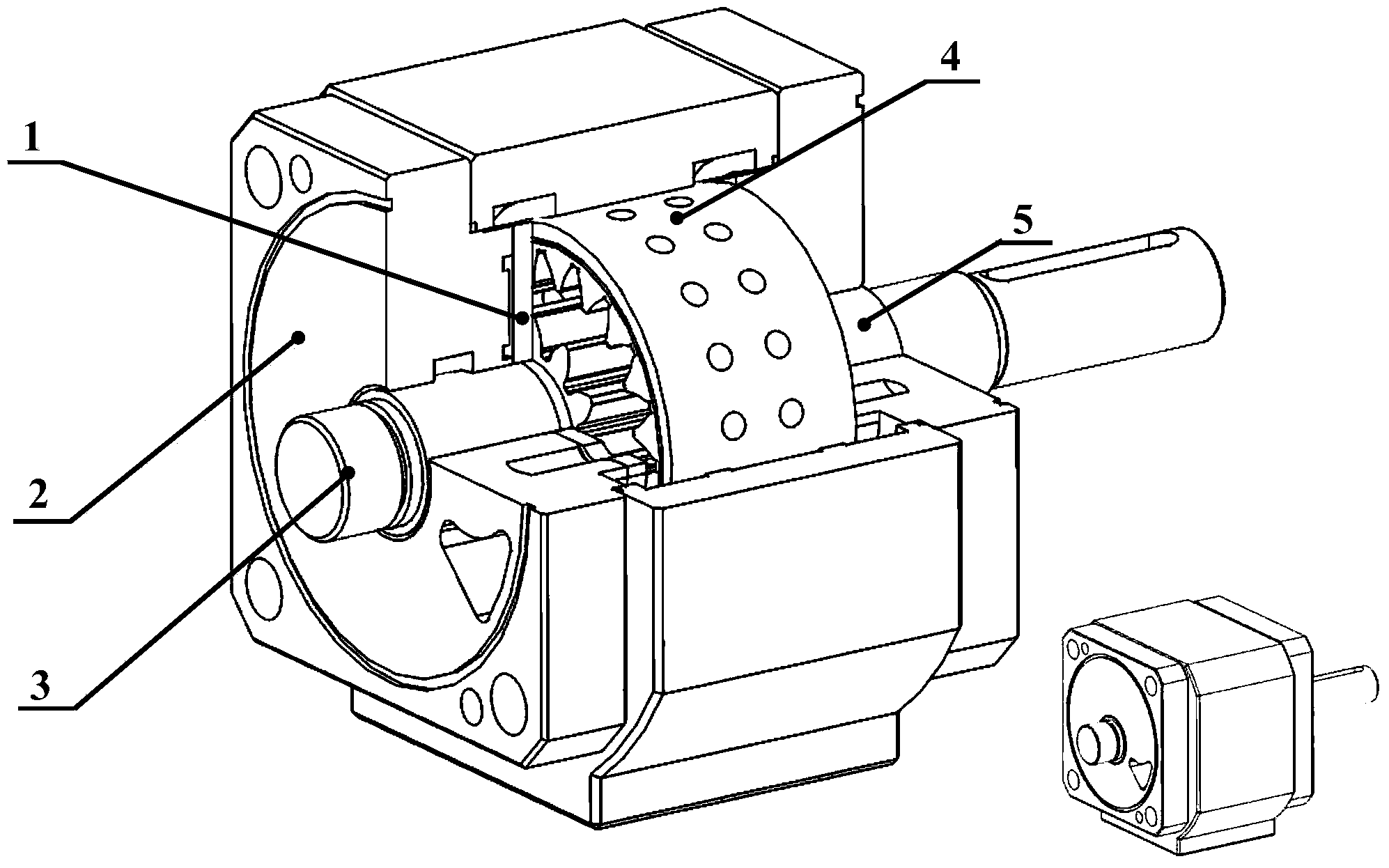

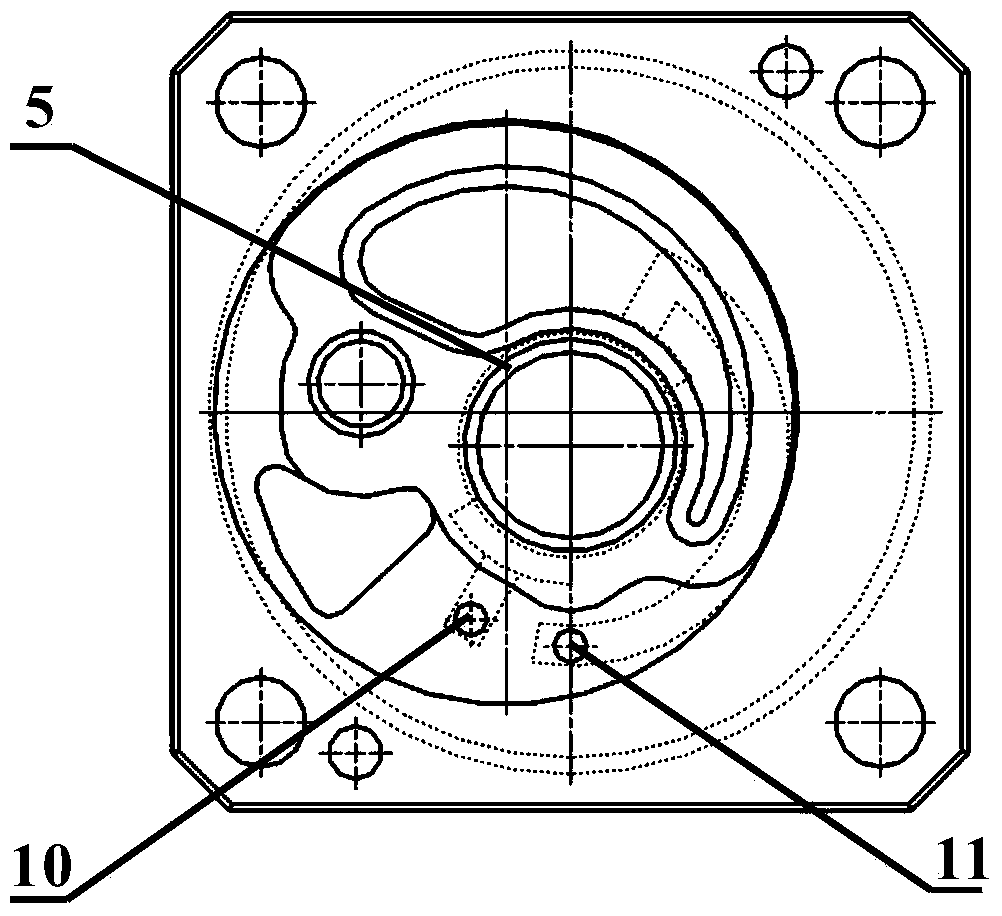

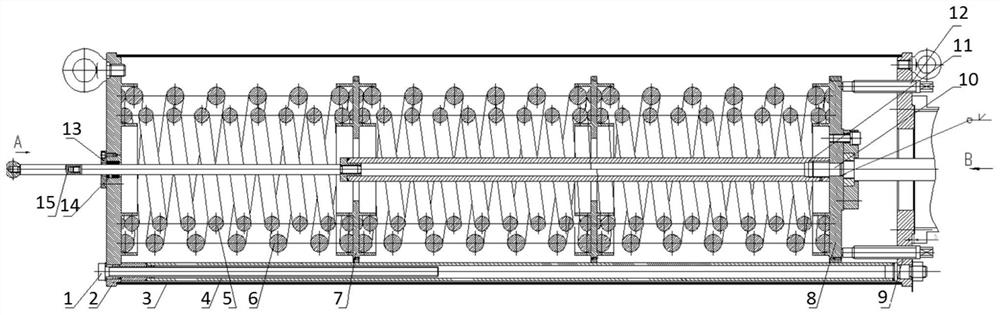

Gas pulse generator

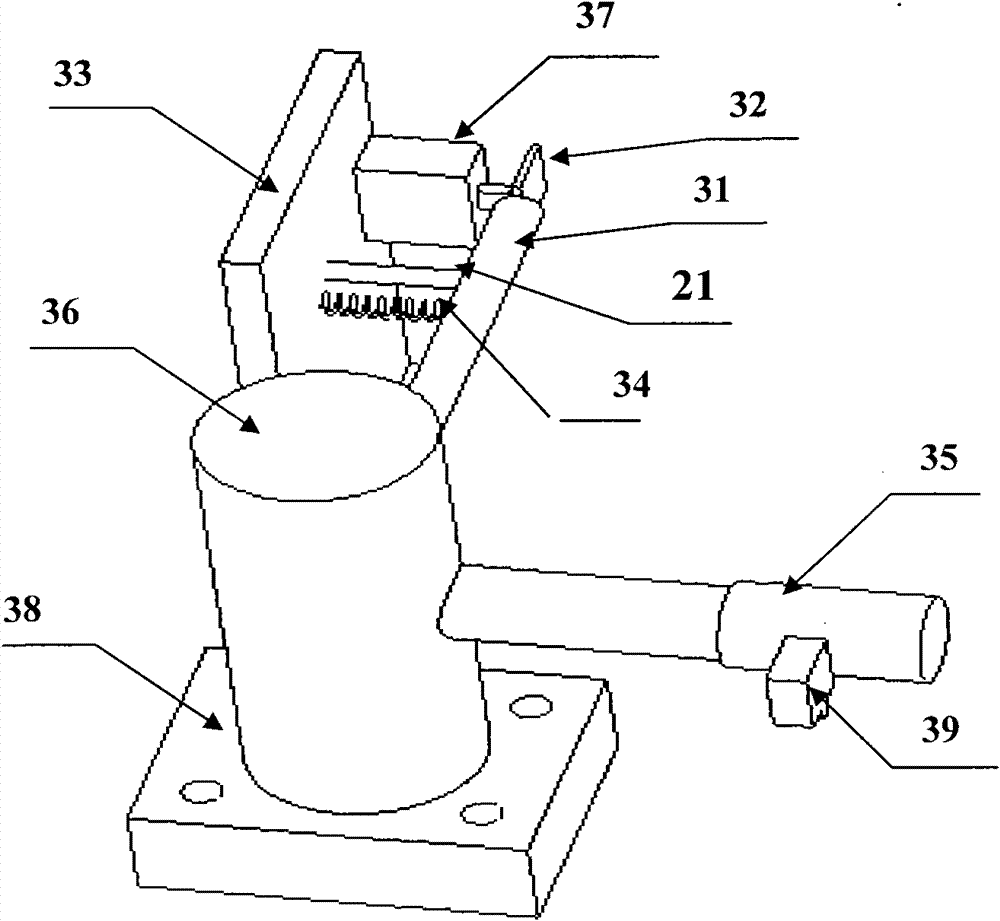

PendingCN110410387AAvoid glue failure problemsAvoid wear failureFog dispersionWeather influencing devicesHigh pressureLubrication

The invention provides a gas pulse generator. The gas pulse generator comprises a motor, a control system, a support frame, a shell body, a gas inlet end cover, a gas inlet port, a gas outlet end cover and a gas outlet port. The gas pulse generator is characterized by further comprising an elastic connection system and a rotor pair, wherein the rotor pair comprises a rotor provided with a gas exhaust hole and a solid lubrication rotor sleeve also provided with a gas exhaust hole, and has a gas check opening-closing function; the solid lubrication rotor sleeve is fixedly and statically installed in the shell body; the rotor is driven to rotate by the motor in the solid lubrication rotor sleeve through the connection of the elastic connection system; the pulse frequency of high-pressure gasis controlled by controlling the rotational speed of the rotor; and the strength of gas pulses is controlled by setting the pressure and flow rate of the gas which flows in. The gas pulse generator iscapable of successfully avoiding the problem of gluing failure of a high-speed large-diameter double-metal solid lubrication bearing and effectively alleviating the problem of wear failure, capable of effectively reducing the heating amount of the double-metal oil-free bearing, capable of enabling high-pressure gas jet to generate strongly discontinuous pulses and then obtaining a strong sound wave with an adjustable frequency, and capable of being used in but not limited to the fields of strong sound wave rain enhancement, fog dispersal, dust removal and the like.

Owner:TSINGHUA UNIV +1

Hydraulic vane pump

InactiveCN101975163AExtend working lifeControl pressureRotary piston pumpsRotary piston liquid enginesWater basedManufacturing technology

The invention discloses a hydraulic vane pump. In the hydraulic vane pump, one or more of sub-vanes are arranged on the lower part of each vane; the bottom of each rotor slot is provided with one or more of pins while the corresponding sub-vane cavities and the pin cavities are formed respectively; auxiliary valves are adopted to control the on / off switching of the pressure fluid passages of the sub-vane cavities or the pin cavities so as to provide pressure fluid for all the cavities or partial cavities selectively, change the total stressed area of the pressure fluid cavities on each vane in the volume-expanding region of the pump. Therefore the pressure on the inner surface of the stator can be controlled reasonably in different pressure stages, the wear failure of the stator can be well avoided, the working pressure of the hydraulic vane pump can be greatly increased, the demand of the high-pressure hydraulic system on the vane pump can be satisfied; the hydraulic vane pump can also have higher working pressure under fluid conditions such as low viscosity medium and high water-based medium; and the manufacturing technology and equipment of the vane pump of the invention are basically the same of that of the existing vane pump, and the manufacturability is better.

Owner:ZHEJIANG TAIZHOU XIANDING HYDRAULIC CO LTD

Blast furnace compaction type vertical stock rod drum shaft composite sealing device

ActiveCN101100700AAvoid wear failureExclude normal maintenanceEngine sealsChecking devicesCouplingEngineering

An improved composite sealer of compact vertical probe in blast furnace is installed between bearing supports and both ends of a body. One end of a coiling shaft assembly works in high temperature zone and the other works in Three sealers are designed at the hot terminal, first one consisting of sealing cover, pressing cover and filler ring; second one consisting of sealing cover and pressing cover in zigzag way; and third one arranged between shaft and pressing cover. A pre-fastened sealer is arranged at cool terminal, consisting of transparent cover, sealing ring with coil and seat. Sealing structure is respectively used at both ends of the bearing seat with water cooling tank. The sealing structure is high-temperature resisting, dust-proof and leakage-proof so as have long service life.

Owner:SHILIN LUOHE METALLURGY EQUIP

Ocean drill rod connector

InactiveCN104863521AReduce wearAvoid depositionDrilling rodsDrilling casingsTorsional strengthScrew thread

The invention discloses an ocean drill rod connector. The ocean drill rod connector comprises a male connector body and a female connector body. The male connector body and the female connector body are provided with an outer thread and an inner thread which are matched with each other respectively. Both the end, away from the outer thread end of the male connector body, of the male connector body and the end, away from the inner thread end of the female connector body, of the female connector body are provided with tapered circular beads. The tapered circular beads are provided with a plurality of reinforcing ribs of a spiral structure at intervals. Spiral grooves are formed between the adjacent reinforcing ribs. According to the ocean drill rod connector, the reinforcing ribs of the spiral structure and the spiral grooves are arranged on the tapered circular beads at intervals, so that the ocean drill rod connector is high in torsional strength, large in load capacity, evenly distributed in stress and capable of meeting the high torsional requirement of ultra deep drilling of an ocean drill rod; the reinforcing ribs and the spiral grooves further have the advantages that the drilling fluid circulation is accelerated, and the corrosion wear resistance is improved, the ocean drill rod can be prevented from being worn untimely and failed, the service life of the drill rod is prolonged accordingly, the drilling efficiency is improved, the drilling cycle is shortened, and the drilling cost is lowered.

Owner:JIANGSU HEXIN PETROLEUM MACHINERY

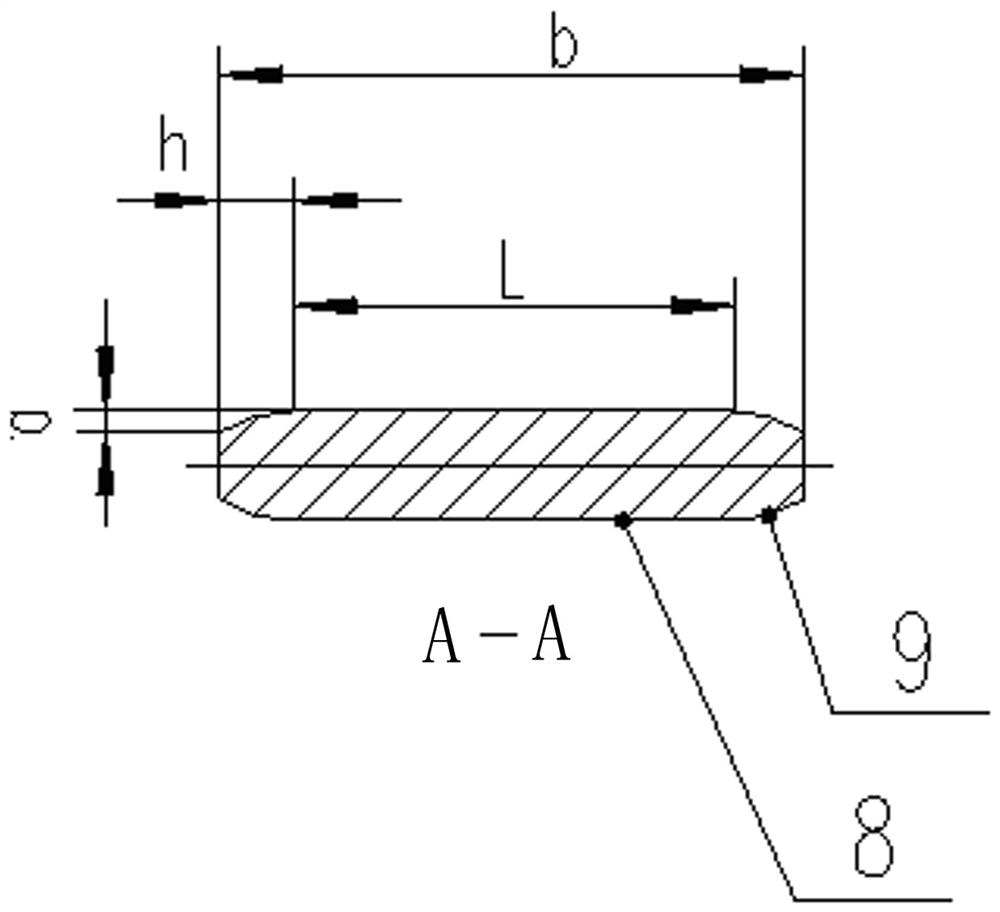

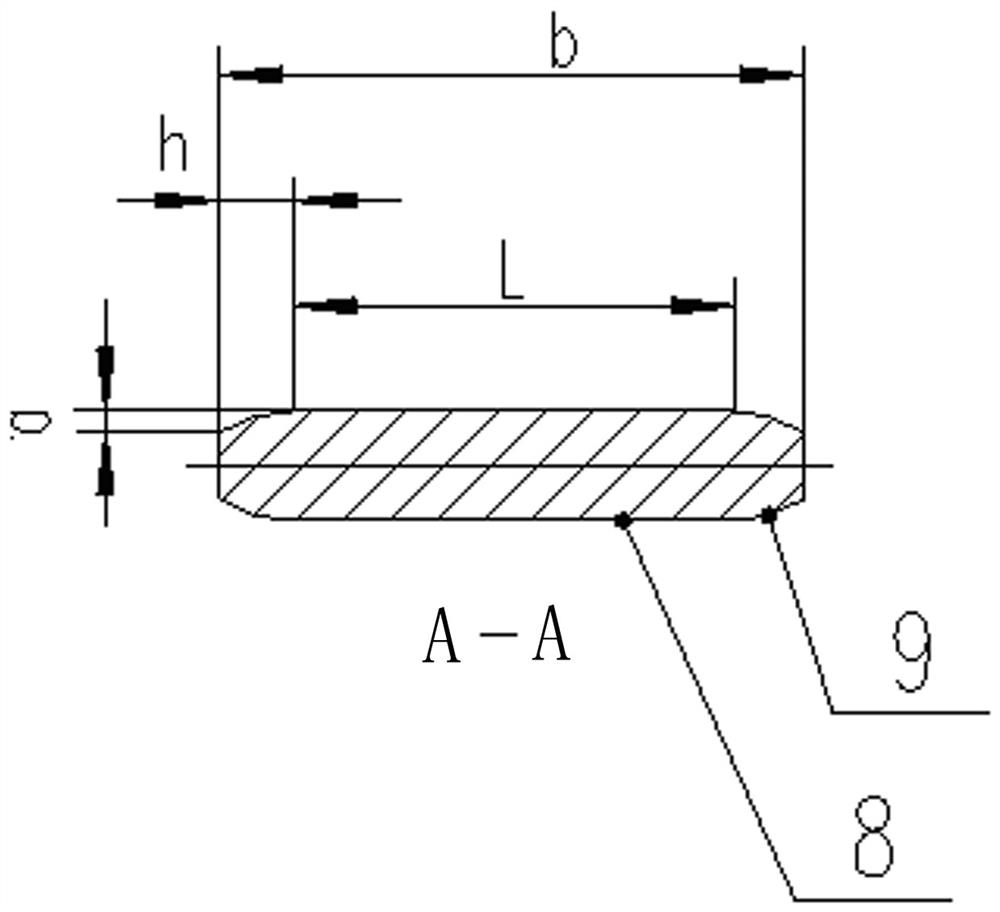

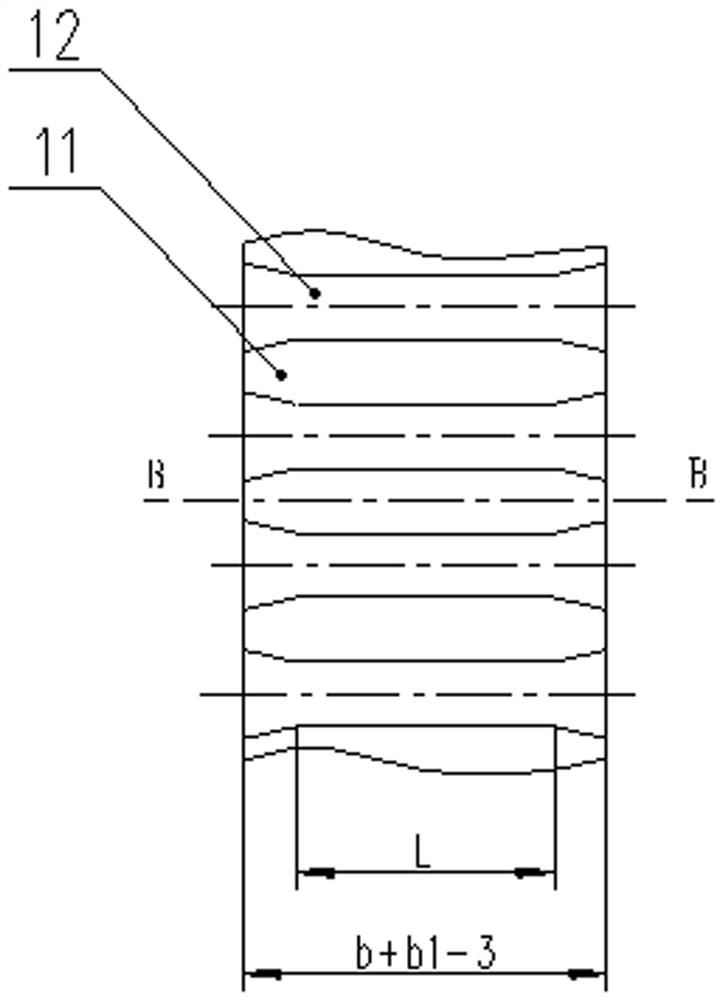

Wear-resistant strip welding structure and method for titanium alloy drill pipe joint

ActiveCN111577158AGood wear resistanceAvoid wear failureDrilling rodsMetallic material coating processesSteel qualityDrill pipe

The invention relates to a wear-resistant strip welding structure and method for a titanium alloy drill pipe joint. The welding structure comprises an intermediate medium layer covering a titanium alloy drill pipe joint body, the intermediate medium layer forms a compact protecting layer on the surface of the titanium alloy drill pipe joint body by high-temperature melting, and a wear-resistant material layer is welded to the compact protecting layer to form a wear-resistant strip. The material of the intermediate medium layer is melted to the titanium alloy of the drill pipe joint to form thecompact protecting layer, and the compact protecting layer has a very strong binding force to the titanium alloy drill pipe joint body and can be melted with a wear-resistant strip material of an existing steel drill pipe joint. The wear-resistant material is enough in hardness and thickness, so that the wear-resistant material has excellent wear-resistant performance. By adding a wear-resistantmaterial layer on the surface of the titanium alloy drill pipe joint, wear-out failure of the titanium alloy drill pipe joint due to frictional wear is avoided, and the service life of the titanium alloy drill pipe joint is prolonged, so that the cost performance of the titanium alloy drill pipe joint is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

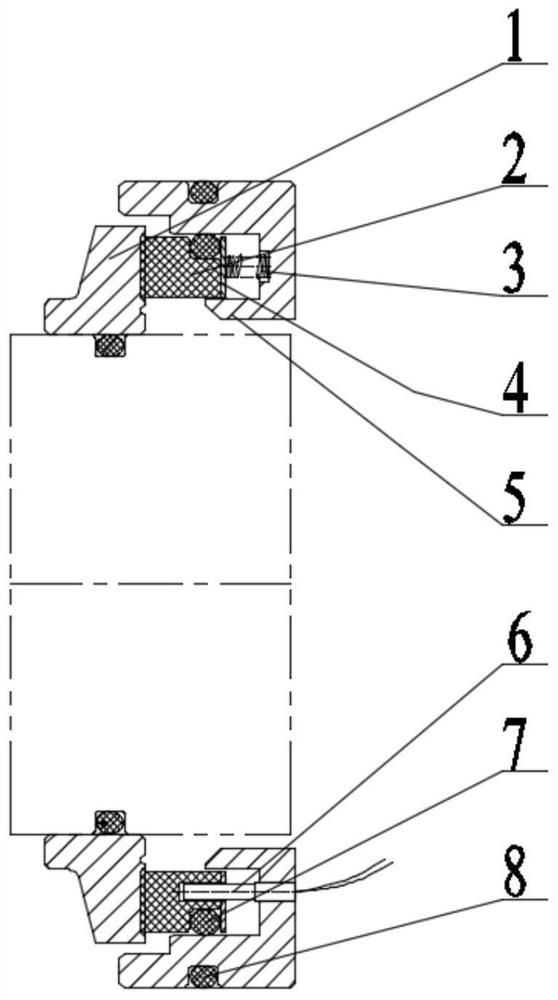

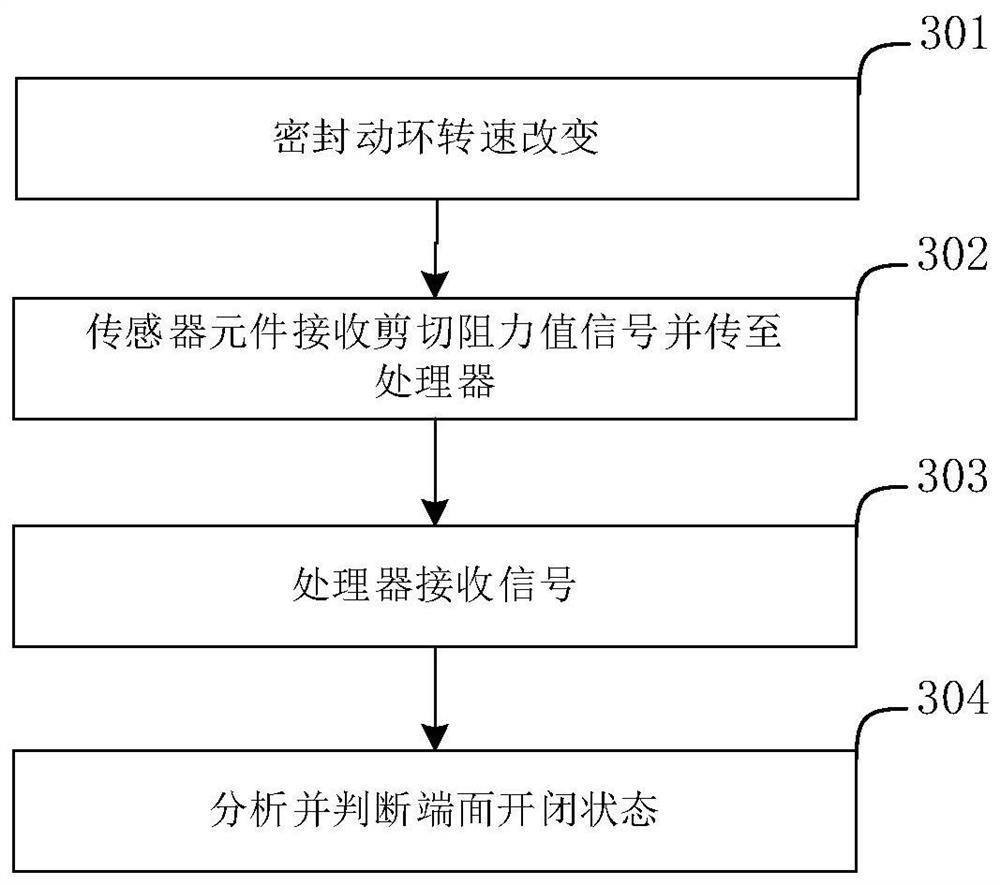

Monitoring type dynamic pressure sealing device and method for monitoring opening and closing state of sealing end face

PendingCN112096879AAvoid wear failureIncrease speedEngine sealsApparatus for force/torque/work measurementControl engineeringElectrical and Electronics engineering

The embodiment of the invention provides a monitoring type dynamic pressure sealing device and method for monitoring the opening and closing state of a sealing end face so as to solve the problem thatthe critical rotating speed of the opening and closing state of a sealing end face cannot be accurately judged in real time in the prior art. The monitoring type dynamic pressure sealing device comprises a sealing moving ring, a sealing static ring, a static ring gasket, a static ring seat, an elastic element and a sensor assembly. According to the embodiment of the invention, the sensor elementis used for detecting a shearing resistance value for preventing the sealing static ring from rotating; under the condition that the shearing resistance is reduced, it is determined that the sealing end face between the sealing moving ring and the sealing static ring is opened; under the condition that the shearing resistance is increased, it is determined that the sealing end face between the sealing moving ring and the sealing static ring is closed; and under the condition that the shearing resistance is not changed, it is determined that the opening and closing state of the sealing end facebetween the sealing moving ring and the sealing static ring is not changed. During use of a seal, the rotating speed can be rapidly increased until the seal end face is opened, a wear rotating speedinterval can be effectively avoided, and seal end face wear failure caused by long-time non-opening of the seal end face is avoided.

Owner:BEIJING UNIV OF CHEM TECH

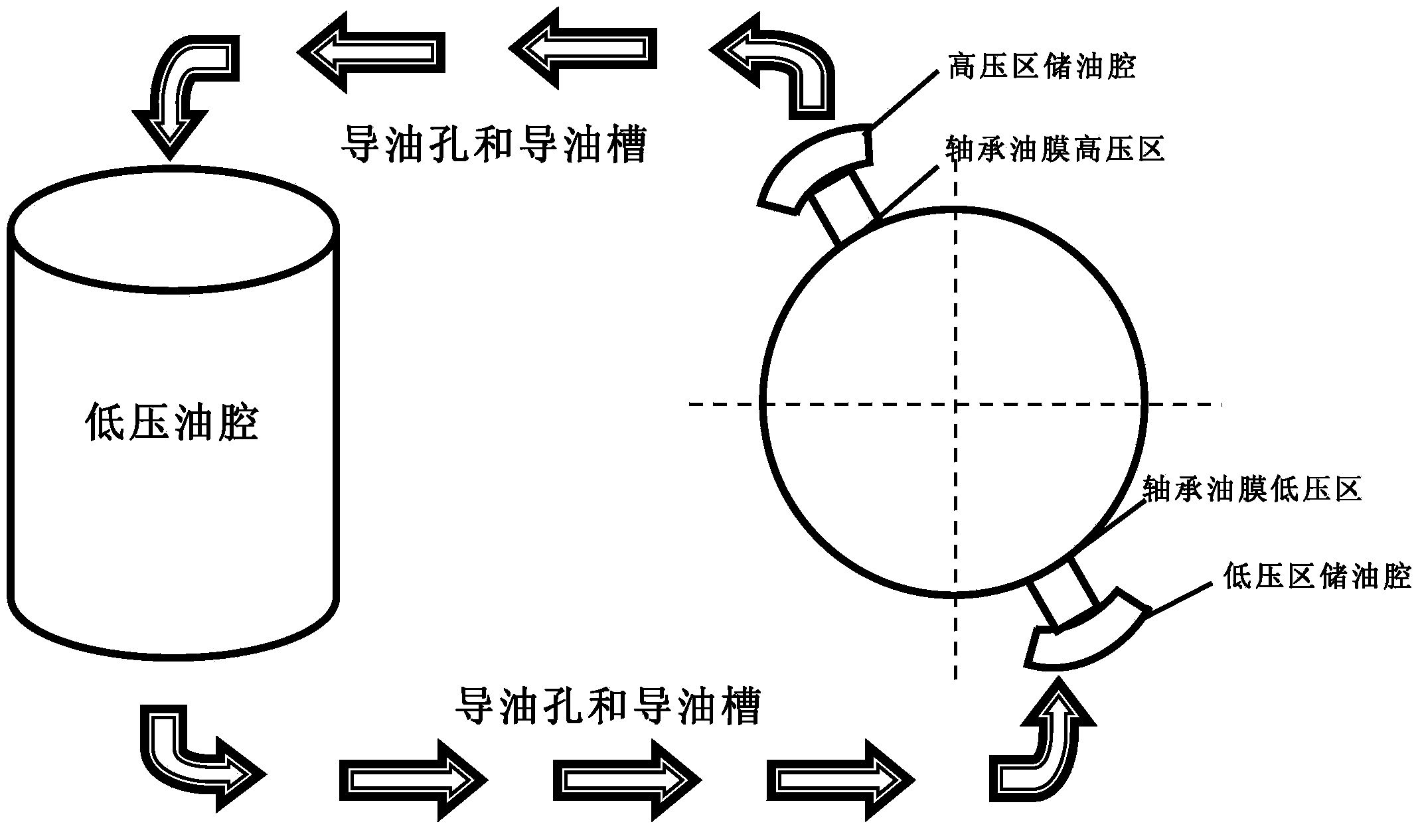

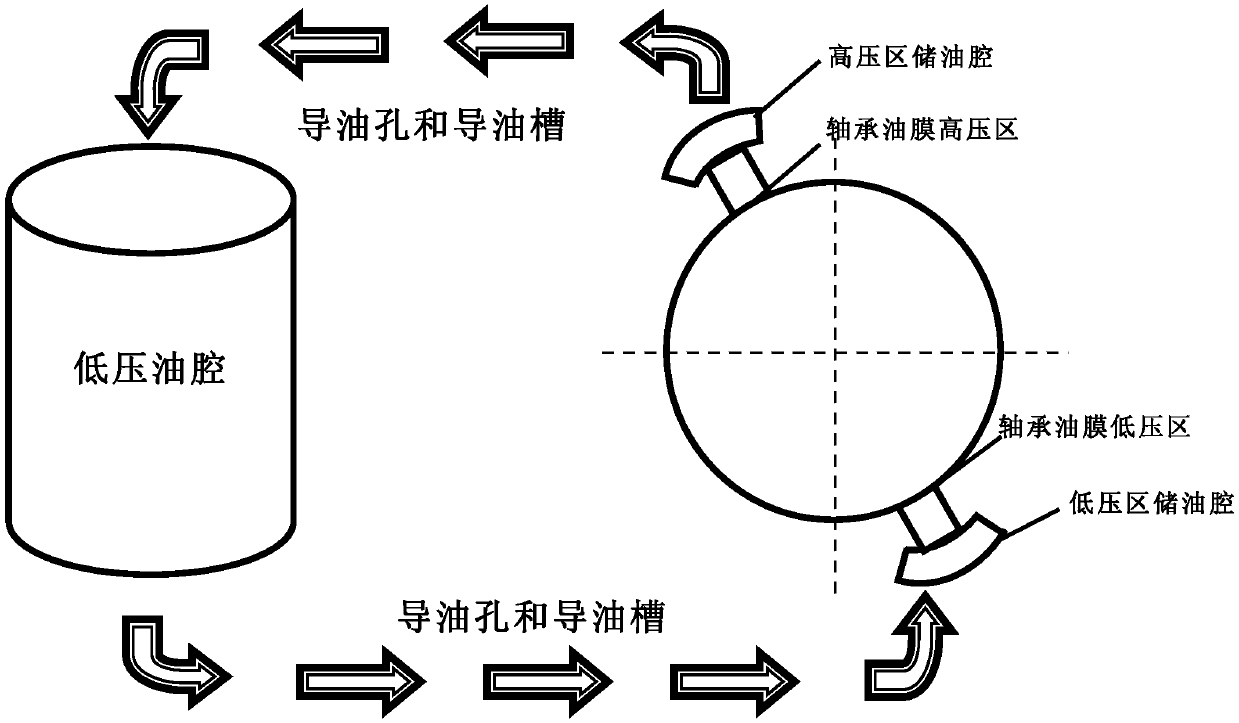

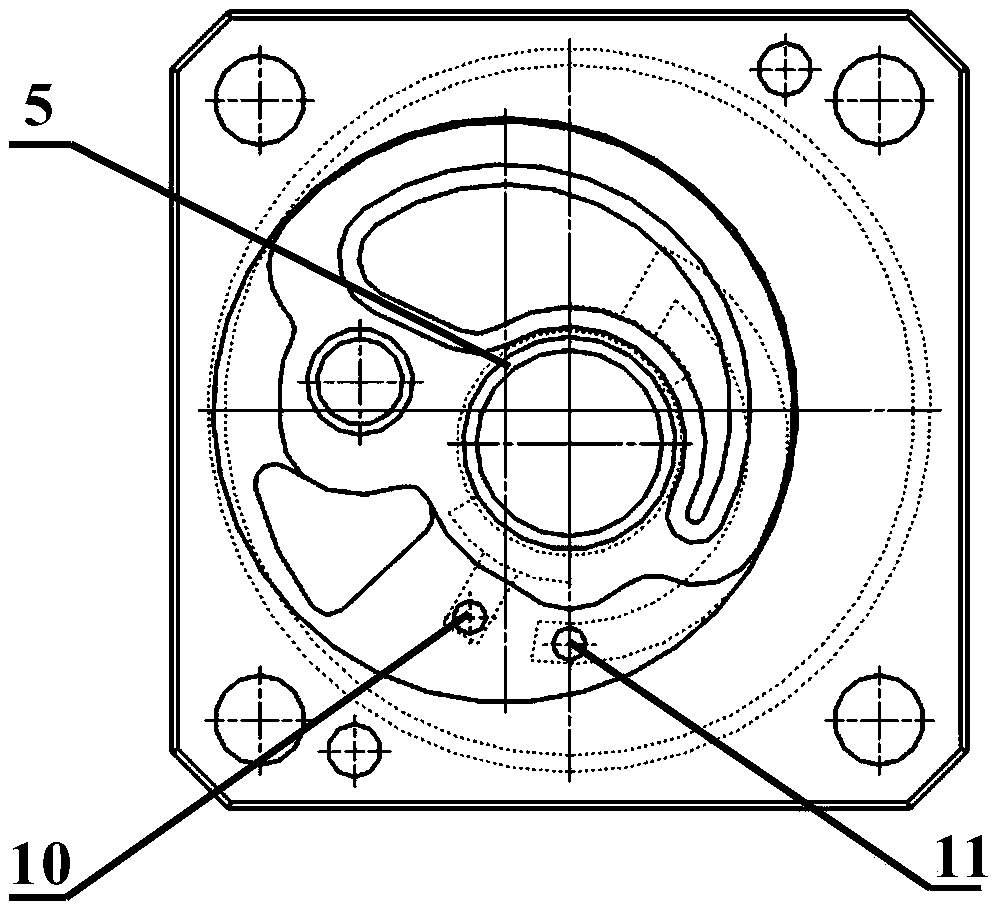

Self-circulating cooling oil lubrication system for sliding bearing for meshing gear pump

ActiveCN104165139AAvoid wear failureExtended service lifeMachines/enginesBearing coolingGear pumpHigh pressure

The invention discloses a self-circulating cooling oil lubrication system for a sliding bearing for a meshing gear pump. The system is characterized in that an oil guide groove and an oil guide hole are formed in the existing sliding bearing of the meshing gear pump and a bearing block in corresponding positions, and the pressure difference between a high pressure region and a low pressure region in a bearing oil membrane is used as driving force, so that on one hand, the oil liquid next to the high pressure region of the oil membrane is guided into a low-pressure oil chamber next to the oil inlet of the gear pump, and on the other hand, the oil liquid can flow to the low pressure region of the oil membrane of the sliding bearing from the low-pressure oil chamber next to the oil inlet of the gear pump, and therefore, a self-circulating cooling loop is formed; for the relatively closed operating environment of the sliding bearing of the meshing gear pump, the quantity of the bearing cooling lubricating oil is increased without greatly reducing the bearing capacity of the bearing so that the bearing can be protected against damage due to overhigh temperature; meanwhile, as the cooling lubricating oil circuit is a self-circulating oil circuit, the axial and radial gap compensation mechanisms of the existing system cannot be damaged and the original volume efficiency of the meshing gear pump is guaranteed.

Owner:ZHEJIANG UNIV

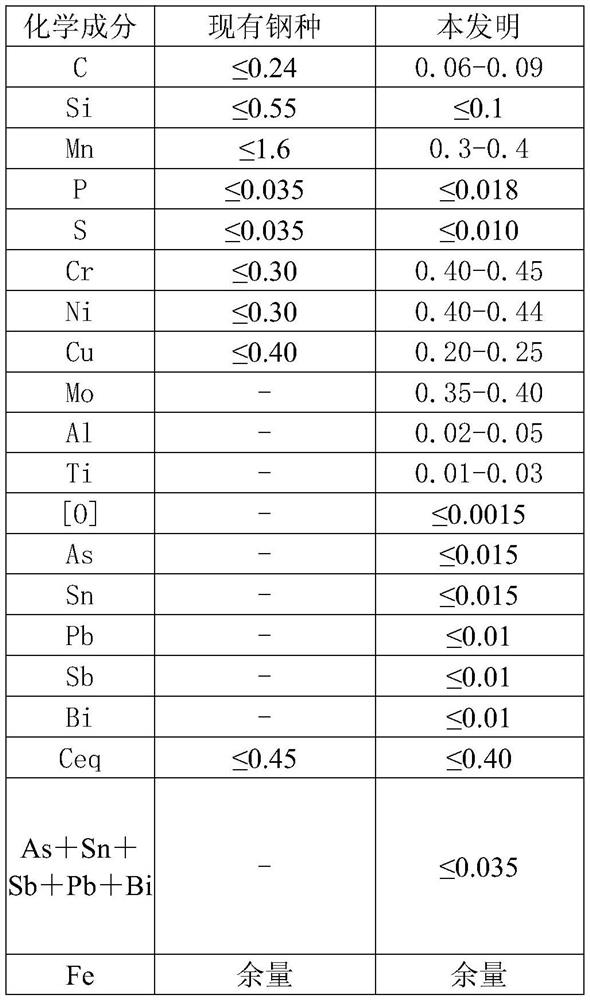

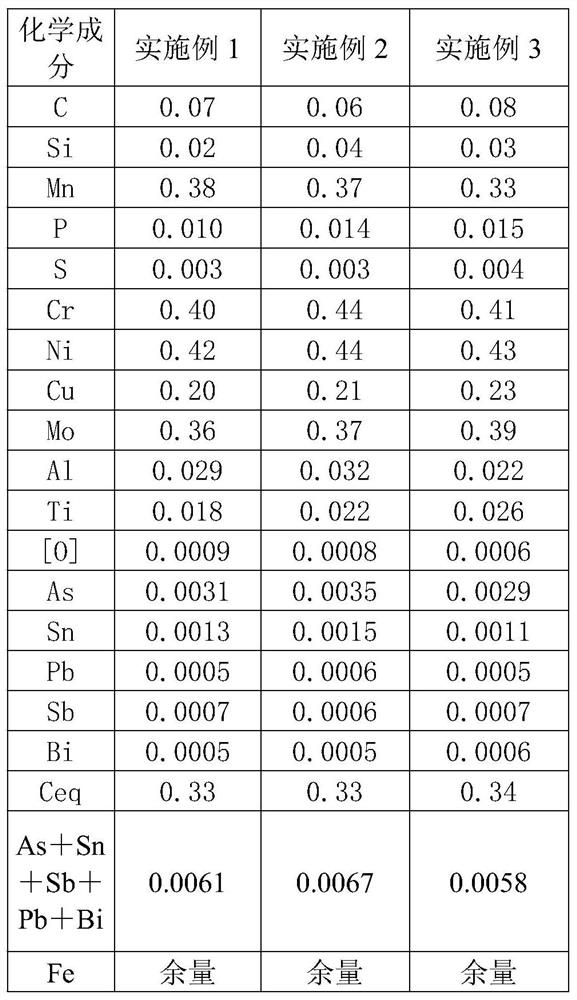

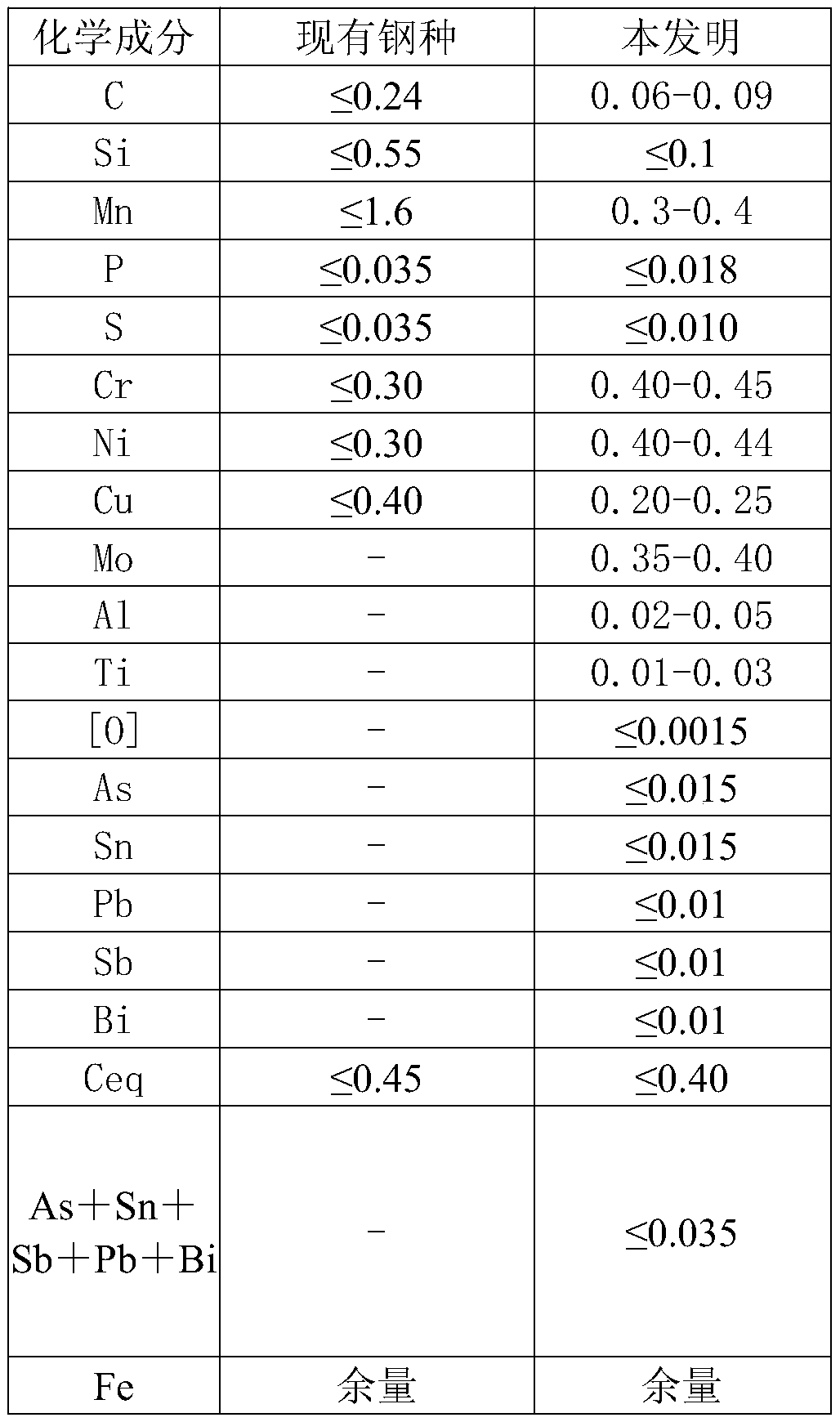

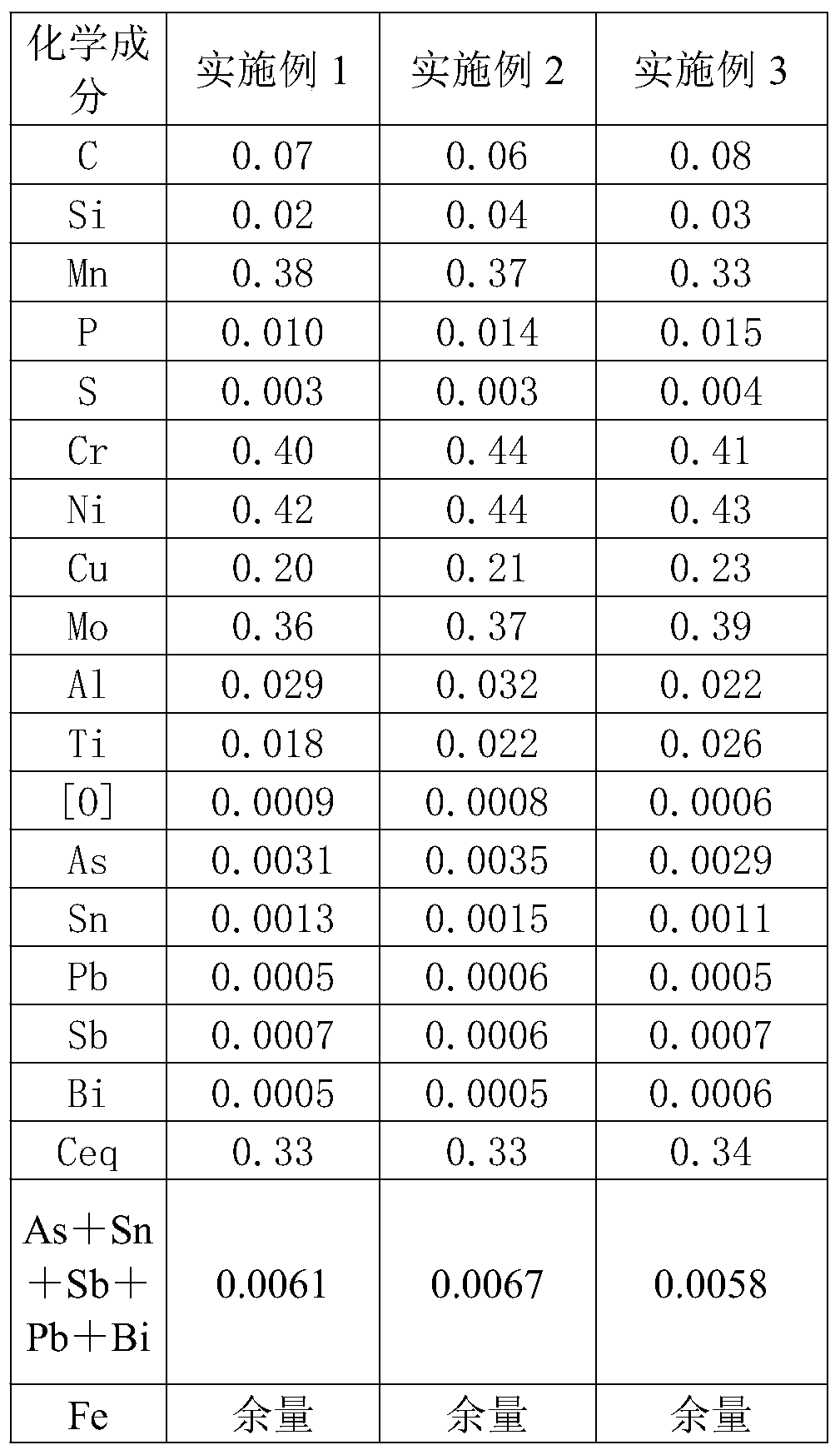

A production method of steel for glass curtain wall pre-embedded fasteners

ActiveCN111455258BHigh precisionImprove toughnessWork heating devicesMetal rolling arrangementsChemical compositionSolderability

The invention discloses a steel for pre-embedded fasteners for glass curtain walls and a production method thereof. The chemical composition mass percentages are C: 0.06%-0.09%, Si: ≤0.10%, Mn: 0.30%-0.40%, Cr: 0.40%‑0.45%, Ni: 0.40%‑0.44%, Mo: 0.35%‑0.40%, Cu: 0.20%‑0.25%, Al: 0.020%‑0.050%, Ti: 0.010%‑0.030%, P≤0.018% , S≤0.010%, [O]≤0.0015%, As+Sn+Sb+Pb+Bi≤0.035%, the balance is Fe. The present invention designs relatively low C, Si, Mn contents, and adds appropriate amount of Cr, Ni, Mo, Cu, Ti, Al and other elements to the steel, so as to ensure the strength, improve the toughness and corrosion resistance of the steel, and at the same time Improve solderability. Compared with the conventional Q355B steel plate, the production method of the present invention reduces the steel plate shearing process and material waste, so the present invention has the advantages of high efficiency, economy, safety and the like, and can well overcome the traditional Q355B steel plate for manufacturing embedded fasteners. Shortcomings, to achieve high-efficiency, energy-saving production, improve market competitiveness.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Tool joint device

ActiveCN104453737BAvoid localized erosionReduce wearDrilling rodsDrilling casingsWell drillingScrew thread

The invention discloses a drill rod joint device which comprises an outer threaded joint and an inner threaded joint in threaded fit with the outer threaded joint. Conical table shoulders are arranged on the outer side of the end, away from an outer threaded segment, of the outer threaded joint and the outer side of the end, away from an inner threaded segment, of the inner threaded joint respectively. A plurality of radial ribs arranged radially are arranged on the conical table shoulders at intervals, and flow passing grooves are formed between the adjacent radial ribs. According to the drill rod joint device, due to the fact that the radial ribs arranged radially and the flow passing grooves are arranged on the conical table shoulders at intervals, the erosion and abrasion resisting capacity of a drill rod joint is high, a drill rod can be prevented from being abraded or damaged too early, therefore, the service life of the drill rod is prolonged, well drilling efficiency is improved, the well drilling period is shortened, and well drilling cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

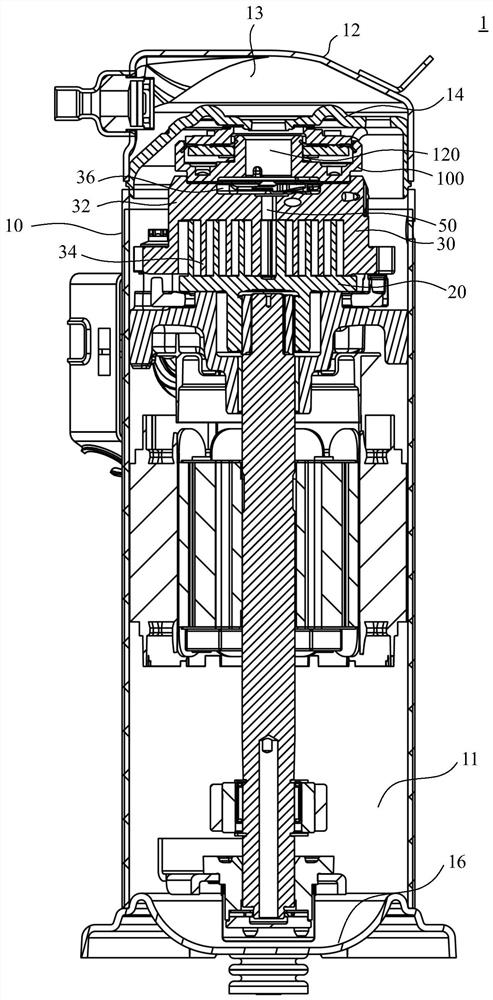

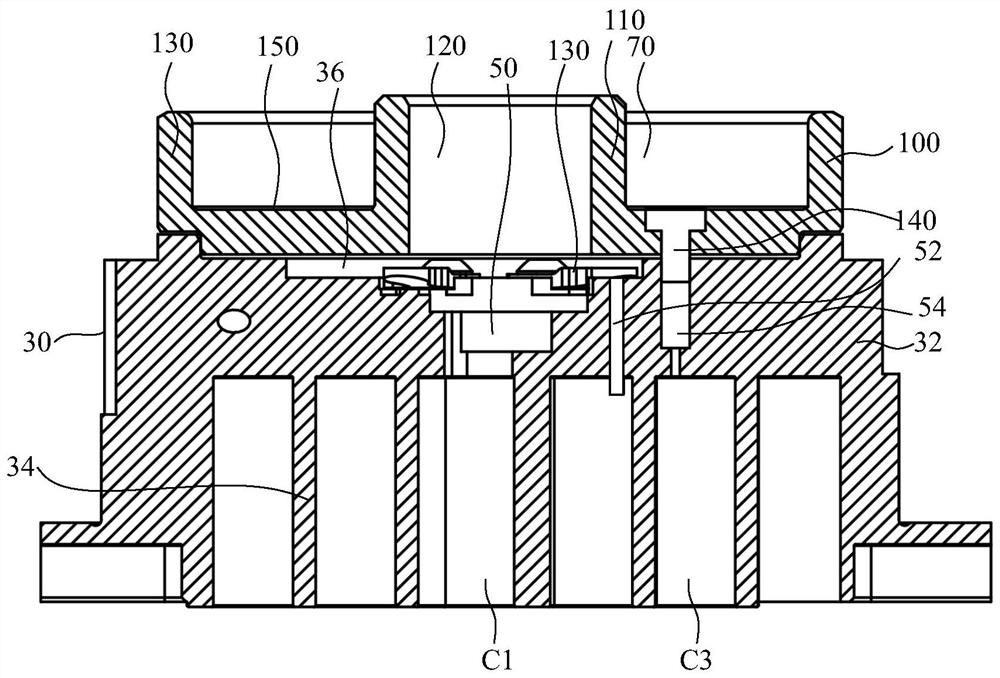

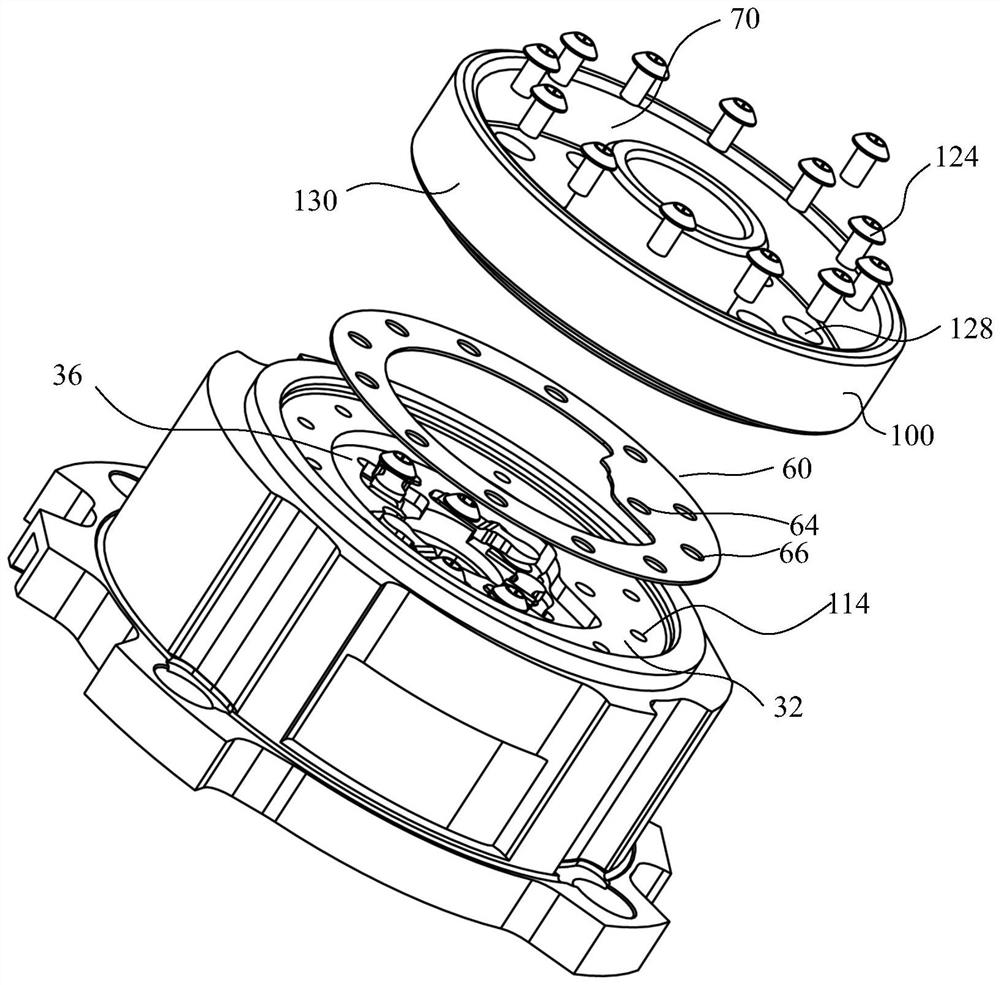

Scroll compression mechanism and scroll compressor

PendingCN113931842AAvoid wear failureExtended service lifeSealing arrangement for pumpsRotary piston pumpsWorking fluidMedium pressure

The invention provides a scroll compression mechanism and a scroll compressor. The scroll compression mechanism comprises a movable scroll and a fixed scroll assembly, wherein the fixed scroll assembly comprises a fixed scroll and a cover plate; the fixed scroll comprises a fixed scroll end plate; the cover plate is fixed to one side of the fixed scroll end plate, so that a central high-pressure concave part capable of being in fluid communication with a middle compression cavity is defined between the cover plate and the fixed scroll end plate; a back-pressure cavity is formed in the side, away from the fixed scroll, of the cover plate; the fixed scroll assembly is further provided with a medium-pressure channel; the medium-pressure channel enables the middle compression cavity to be in fluid communication with the back-pressure cavity; a sealing reinforcing structure for defining a sealing reinforcing area is arranged between the cover plate and the fixed scroll end plate; and the medium-pressure channel penetrates through the sealing reinforcing area, so that working fluid is prevented from leaking to the medium-pressure channel from the central high-pressure concave part. According to the scroll compression mechanism provided by the invention, the abrasion failure of the scroll compression mechanism can be prevented, the service life of the scroll compression mechanism is prolonged, and the use performance of the scroll compression mechanism is improved.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

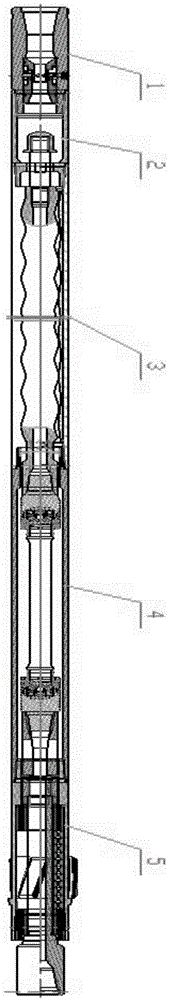

Anti-leakage well flushing packer

InactiveCN105587286BAvoid wear failureAvoid Creep FailureFlushingSealing/packingUpper jointEngineering

The invention discloses an anti-losing well-flushing packer. The packer comprises an upper joint, an upper shell, a center pipe, a lower shell and a lower joint which are sequentially connected from top to bottom; a packing cup assembly is arranged on the outer side of the center pipe, and a one-way switch valve is arranged inside a cylinder jointly formed by the lower shell and the lower joint; an overflowing hole communicated with the center pipe is formed in the side wall of the upper shell, and a suction opening communicated with the center pipe and the one-way switch valve at the same time is formed in the side wall of the lower shell; and the one-way switch valve comprises a flow dividing body, a valve cover, a stainless steel valve ball and a valve ball spring. The flow dividing body is fixed to the inner wall of the lower joint, the valve cover is connected to the top of the flow dividing body, and the stainless steel valve ball is arranged on the opening in the top of the flow dividing body; and a step is arranged on the inner wall of the flow dividing body, and the valve ball spring is arranged between the stainless steel valve ball and the step of the inner wall of the flow dividing body. According to the anti-losing well-flushing packer, during oil well flushing, flushing fluid can be effectively prevented from being lost and entering a stratum, the packer is reliable in sealing, wear-resisting, creep-resisting and capable of effectively preventing a ball seat from being buried by sand, and during well repairing work, oil can be drained.

Owner:CHINA PETROLEUM & CHEM CORP +1

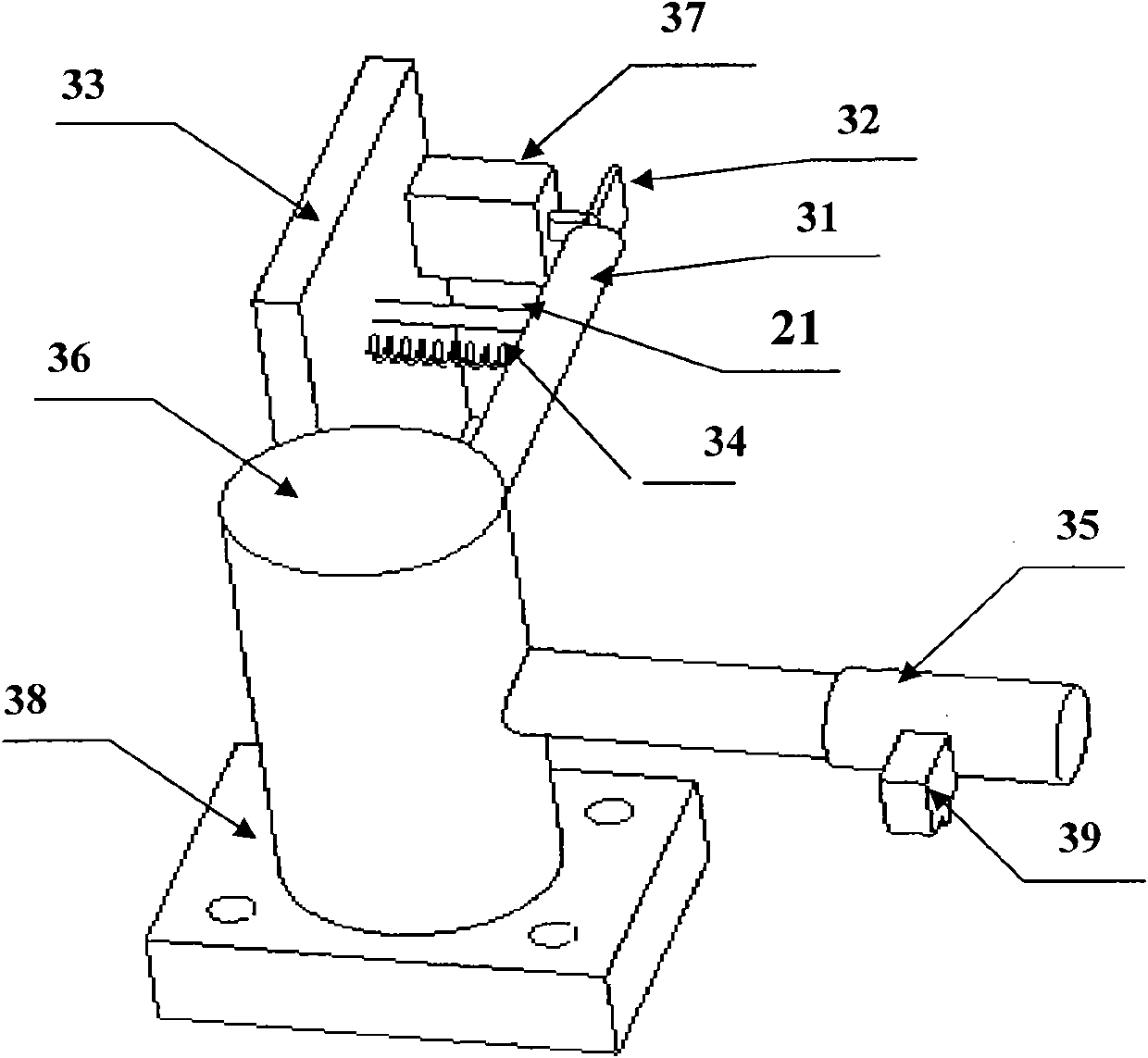

Hydraulic servo-motor control seat spring box

PendingCN112253265AAnti-vibrationWith anti-vibration performanceMachines/enginesEngine componentsMotor controlImpact

The invention relates to a hydraulic servo-motor control seat spring box. The spring box comprises a box body, a guide rod (4), a guide sleeve, a spring and a connector rod (15) are arranged in the box body, the guide rod (4) is connected with the box body, one end of the guide sleeve is connected with the box body, the other end of the guide sleeve is connected with the connector rod (15) in a sliding mode, the guide sleeve and the connector rod (15) are sleeved with the spring, a wear-resistant copper sleeve is installed at the end, close to the guide rod (4), of the guide sleeve and connected with the guide rod (4) in a mechanical contact mode. The hydraulic servo-motor control seat spring box has the advantages of vibration prevention, vibration resistance, impact and abrasion resistance, collision and abrasion prevention, long service life and the like. Under the conditions of large torque, long stroke and horizontal installation, the vibration amplitude and impact abrasion of equipment can be effectively reduced, the abrasion failure of the spring is avoided, the reliability of the hydraulic servo-motor control seat spring box is greatly improved, and the safe and stable operation of a unit is effectively ensured.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

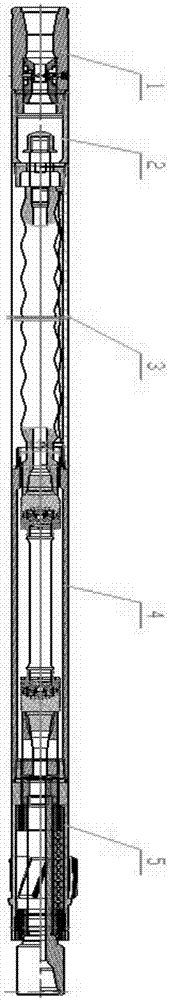

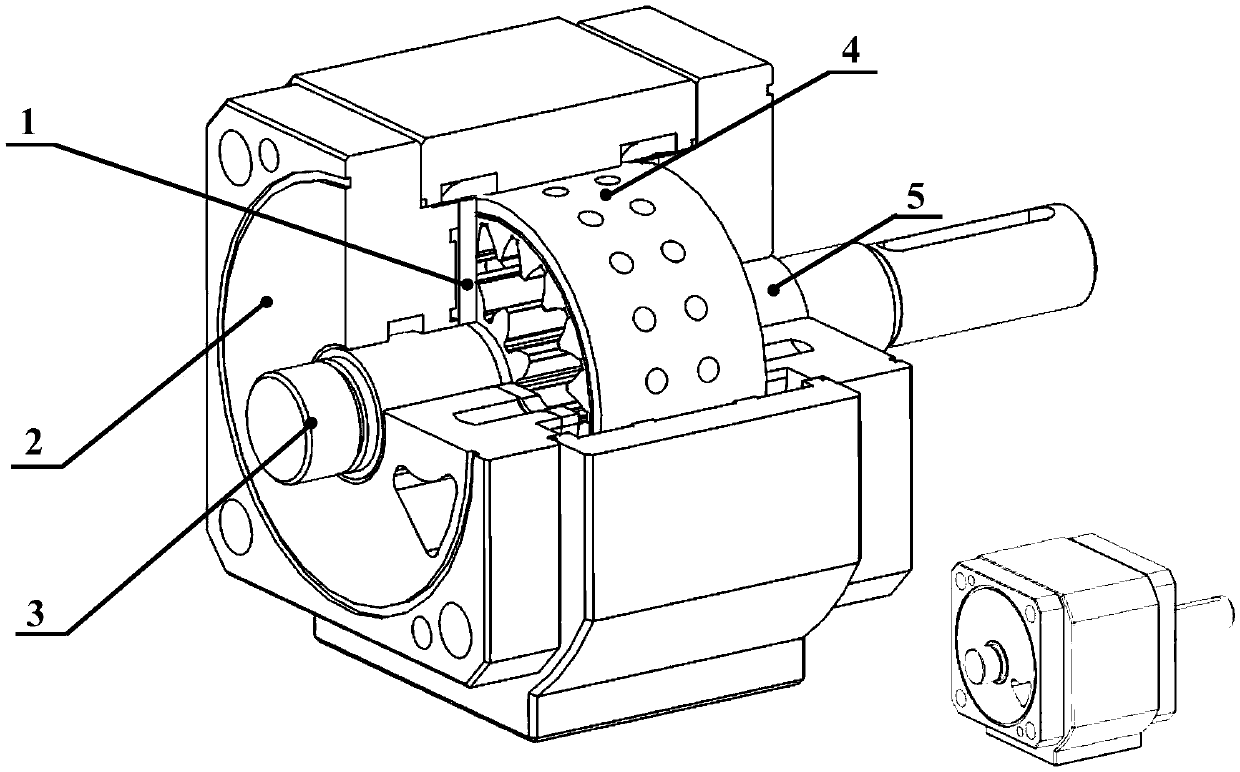

Downhole High Efficiency Screw Drilling Tools

ActiveCN103883246BImprove efficiencyAdapt to the needs of drillingBorehole drivesUniversal jointEngineering

An efficient positive displacement motor under a well comprises a bypass valve assembly, a falling prevention joint, a motor joint, a universal joint assembly and a bearing joint assembly. The efficient positive displacement motor under the well is simple in structure, convenient to use, stable in operation under the well, safe, reliable, high in complete machine efficiency, capable of outputting larger torque, long in working time and service life, suitable for drilling needs of various complex wells at the present, free of piercing leakage and high in working reliability. A streamlined flow channel enables water conservancy losses of a main flow channel to be reduced, turn-off force is large, the defects of the interference effect and tooth form distortion of the conjugation curvature of a traditional single-screw machine type positive displacement motor are overcome, a universal shaft operates flexibly, energy efficiency is high, the universal shaft can work in the environments where no sand grain exists, and drilling fluid erosion exists, the service life is long, and mechanism strength is high.

Owner:QINGDAO JINJIANGYUAN IND EQUIP CO LTD

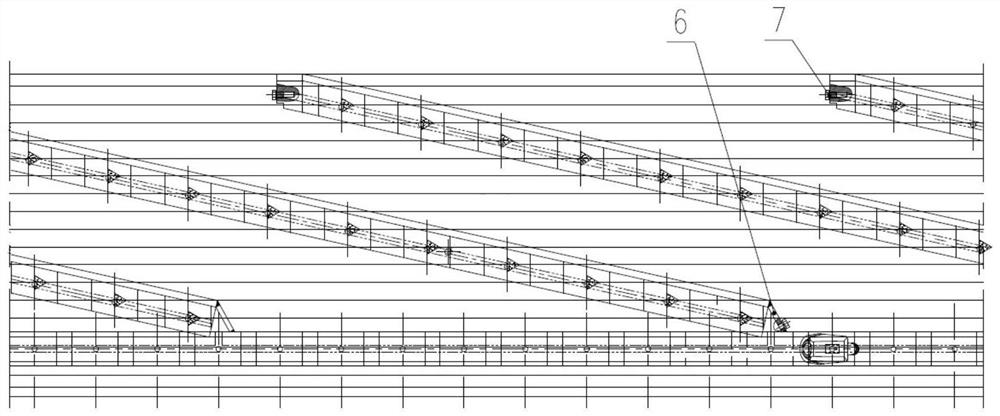

Water passing device and maintenance method thereof

PendingCN114412460AAvoid wear failureImprove reliabilitySlitting machinesWorking environmentStructural engineering

The invention relates to a water passing device and a maintenance method thereof. The water passing device comprises a cylinder ring end disc water passing hole and a cylinder ring connecting disc water passing hole which are formed in the cylinder ring, an end disc water passing groove, an end disc connecting water passing groove and an end disc water passing hole which are formed in the end disc, and blade water passing grooves and blade water passing holes which are formed in the blades. The water inlet channel is formed in the connecting disc, the triangular water tank is arranged at the joint of the end disc and the starting end of the blade, the water inlet channel, the cylinder ring connecting disc water through hole, the blade water through groove and the blade water through hole are sequentially communicated, and the cylinder ring end disc water through hole, the end disc connecting water through groove, the end disc water through groove and the end disc water through hole are communicated. The triangular water tank is communicated with the blade water through tank and the end disc connecting water through tank at the same time; the maintenance method of the water supply device comprises the step of respectively inserting flexible steel bars into the water channels in the end disc and the blades to clean the corresponding water channels. Abrasion and sealing-off failure in use can be avoided, maintenance is easy, the service life of the roller can be prolonged, and the safety of the underground working environment is improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Exhaust brake valve for engine

PendingCN108317013AReduce failureImprove partial wearEngine controllersMachines/enginesAgricultural engineeringExhaust brake

Owner:DONGFENG COMML VEHICLE CO LTD

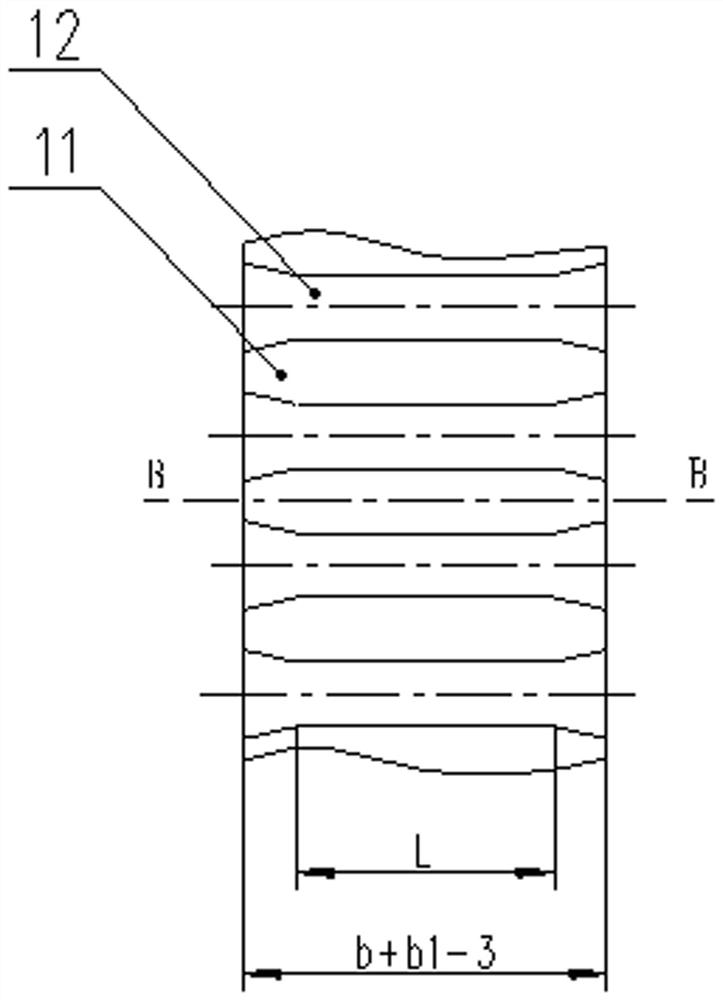

Tooth profile modification design method and processing method for involute spline and gear products of involute spline

ActiveCN112059082AImproved contact load distributionGuaranteed axial fit lengthGear wheelsRooted toothStructural engineering

The invention discloses a tooth profile modification design method for an involute spline. The design method comprises the steps that the tooth directions of tooth faces, tooth crests and tooth rootsat the two ends of spline teeth are subjected to arc modification; the tooth faces of the internal and external spline teeth are in contact with the middle sections of the teeth without profile modification; and the length L of the middle sections of the spline teeth which are not modified is calculated according to an involute spline bearing capacity calculation formula 2T103 / LpsiZHD< / =[sigma p].According to the modification method, the tooth face contact load distribution condition is directly improved, the unbalance loading is reduced, and abrasion failure caused by the increase of the unit area load is avoided. Enough axial matching length of the spline teeth is ensured, so that the spline matching and centering precision is ensured, and the quality of gear products is greatly improved. Moreover, the invention discloses a profile modification processing method for the involute spline, the processing method is high in efficiency, no cuttings are generated, the strength is high, andthe method is simple, reliable and easy to implement.

Owner:HANDE AXLE (ZHUZHOU) GEAR CO LTD

Protection device for abnormal movement during lift car leveling opening

The invention discloses a protection device for abnormal movement during lift car leveling opening, which can prevent a lift car from moving when a lift car door is in an open mode. The protection device of the invention comprises control devices, action protection devices, bearing devices, a supporting part, an electric protection device and a warning device, wherein the control devices are fixed at the bottoms of two sides of the lift car door; the action protection devices are fixedly installed at the heads of two sides of the supporting part, and the middle part of the supporting part is connected with the bottom of the lift car; each bearing device is arranged in each leveling position in the shaft wall, and is matched with the corresponding action protection device; each action protection device is driven by the corresponding control device to reciprocate; when the lift car door is completely opened, the control devices drive the action protection devices to be embedded into the bearing devices, and keep the balance of the whole lift car when the lift car generates a movement trend; the electric protection device cuts off the electric circuit of a lift when the lift car is in the process of opening; and the warning device actuates a warning circuit when the lift car generates a gliding trend, and warns to prevent the use of the lift in an abnormal state.

Owner:HITACHI ELEVATOR CHINA

A titanium alloy drill pipe joint wear-resistant band welding structure and method

ActiveCN111577158BExtended service lifeCost-effectiveDrilling rodsMetallic material coating processesTitanium alloyProtection layer

A titanium alloy drill pipe joint wear-resistant belt welding structure and method, the welding structure includes an intermediate medium layer covering the titanium alloy drill pipe joint body, and the intermediate medium layer is melted on the titanium alloy drill pipe joint body after high temperature A dense protective layer is formed on the surface, and a wear-resistant material layer is welded on the dense protective layer to form a wear-resistant belt. The material of the intermediate medium layer melts with the titanium alloy of the drill pipe joint at high temperature to form a dense protective layer. The dense protective layer not only has a strong bonding force with the body of the titanium alloy drill pipe joint, but also can be combined with the existing steel The wear-resistant band material of the drill pipe joint is effectively fused, and the wear-resistant material layer has sufficient hardness and thickness, and has excellent wear resistance. The invention realizes adding a wear-resistant material layer on the surface of the titanium alloy drill pipe joint, avoids the wear failure problem of the titanium alloy drill pipe joint caused by friction and wear, improves the service life of the titanium alloy drill pipe joint, and thus improves the durability of the titanium alloy drill pipe cost-effective.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

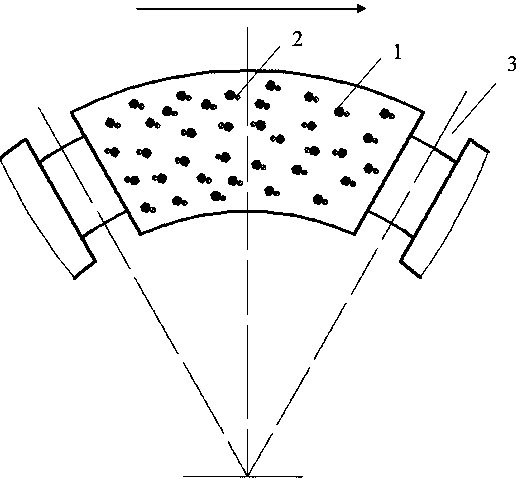

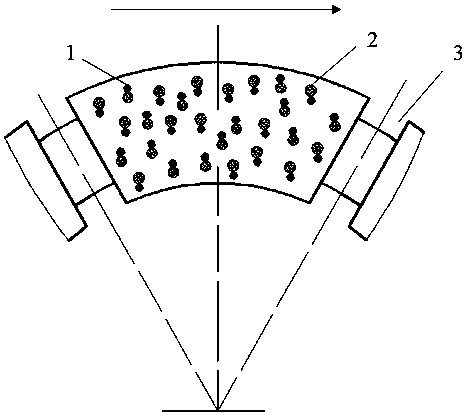

Diamond bit containing hard brittle abrasive particles and manufacture process thereof

The invention discloses a diamond bit containing hard brittle abrasive particles and a manufacture process thereof. The bit comprises a carcass, wherein multiple groups of abrasive particles are arranged in the carcass, each group of abrasive particles include diamond abrasive particles and hard brittle abrasive particles, and the diamond abrasive particles and the hard brittle abrasive particlesoverlap on each other. The manufacture process comprises the following steps: (1) shaping and screening the hard brittle abrasive particles; (2) punching in a template; (3) premoulding carcass sheets;(4) paving abrasive particles with coarse particle diameter on the carcass sheets; (5) paving abrasive particles with fine particles on the carcass sheets; and (6) combining and performing cold pressmolding on multiple layers of carcass sheets. The diamond bit disclosed by the invention solves the problem of instability of bit performance caused by relative position difference factors of the hard brittle abrasive particles and the diamond in the carcass, and increases the batch performance stability and drilling efficiency of the bit.

Owner:HUNAN UNIV OF SCI & TECH

Sliding bearing self-circulation cooling oil lubrication system for meshing gear pump

ActiveCN104165139BAvoid wear failureExtended service lifeMachines/enginesBearing coolingGear pumpPressure difference

Owner:ZHEJIANG UNIV

Blast furnace compaction type vertical stock rod drum shaft composite sealing device

An improved composite sealer of compact vertical probe in blast furnace is installed between bearing supports and both ends of a body. One end of a coiling shaft assembly works in high temperature zone and the other works in Three sealers are designed at the hot terminal, first one consisting of sealing cover, pressing cover and filler ring; second one consisting of sealing cover and pressing cover in zigzag way; and third one arranged between shaft and pressing cover. A pre-fastened sealer is arranged at cool terminal, consisting of transparent cover, sealing ring with coil and seat. Sealing structure is respectively used at both ends of the bearing seat with water cooling tank. The sealing structure is high-temperature resisting, dust-proof and leakage-proof so as have long service life.

Owner:SHILIN LUOHE METALLURGY EQUIP

All-formation cutter for earth pressure balance shield machine

The invention relates to an all-formation cutter for an earth pressure balance shield machine, comprising a cutter flange, leg structures, a cutter center, a cutter periphery, a cutter outer ring, cutter spokes, a cutter panel, an opening area and the like; main structure of the cutter is made with high-strength steel plates; a wear-resistant composite steel plate is laid and welded to the front of the cuter; two sides of the wear-resistant composite steel plate are different in material, the wear-resistant side is made with a chromium carbide steel plate, the other side has good welding performance in order to ensure the quality of laying welding, and the part where a wear-resistant composite steel plate is unable to be laid is provided with a wear-resistant welded layer by surfacing; twosteel tubes 20 mm inn diameter are laid on the front surface of the cutter along the diameter direction of the cutter in crossing manner; the steel tubes are filled with hydraulic oil and connected to a hydraulic oil line; whether the cutter is abraded is judged according to changes in the pressure of the hydraulic oil line. The all-formation cutter has the advantages that wear resistance of thecutter can be improved, the service life of the cutter can be extended, abrasion of a tool and the cutter can be monitored in real time, the tool can be changed in time to prevent abrasion of the cutter, and the all-formation cutter is applicable to shielding for all-formation geological conditions.

Owner:辽宁三三工业有限公司

Involute spline spline tooth modification design method and processing method and gear product thereof

ActiveCN112059082BImproved contact load distributionGuaranteed axial fit lengthGear wheelsRooted toothGear wheel

Owner:HANDE AXLE (ZHUZHOU) GEAR CO LTD

Steel for pre-embedded fastener of glass curtain wall, and production method thereof

ActiveCN111455258AHigh strengthImprove toughnessWork heating devicesMetal rolling arrangementsSolderabilityUltimate tensile strength

The invention discloses steel for a pre-embedded fastener of a glass curtain wall, and a production method thereof. The steel for the pre-embedded fastener of the glass curtain wall comprises the following chemical components in percentage by mass: 0.06%-0.09% of C, not greater than 0.10% of Si, 0.30%-0.40% of Mn, 0.40%-0.45% of Cr, 0.40%-0.44% of Ni, 0.35%-0.40% of Mo, 0.20%-0.25% of Cu, 0.020%-0.050% of Al, 0.010%-0.030% of Ti, not greater than 0.018% of P, not greater than 0.010% of S, not greater than 0.0015% of [O], and the balance Fe, wherein As+Sn+Sb+Pb+Bi is not greater than 0.035%. According to the steel for the pre-embedded fastener of the glass curtain wall, and the production method thereof, low C content, Si content and Mn content are designed, and appropriate amounts of elements Cr, Ni, Mo, Cu, Ti, Al and the like are added in the steel, so that the toughness and the corrosion resistance of the steel are improved while the strength is guaranteed, and meanwhile, the weldability is improved. According to the production method, compared with a common Q355B steel plate, cutting procedures for the steel plate, and material waste are reduced, and therefore, the production method has the advantages of being efficient, economic, safe and the like, is capable of greatly overcoming the defects of a method for manufacturing a pre-embedded fastener from the Q355B steel plate,realizes efficient and energy-saving production, and improves the market competitiveness.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com