Sliding bearing self-circulation cooling oil lubrication system for meshing gear pump

A sliding bearing and lubrication system technology, which is applied in the direction of bearing cooling, bearing components, shafts and bearings, etc., can solve the problems of sliding bearing failure and damage, limit the service life of sliding bearings in meshing gear pumps, etc., so as to avoid bearing wear failure and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the implementation examples shown in the accompanying drawings.

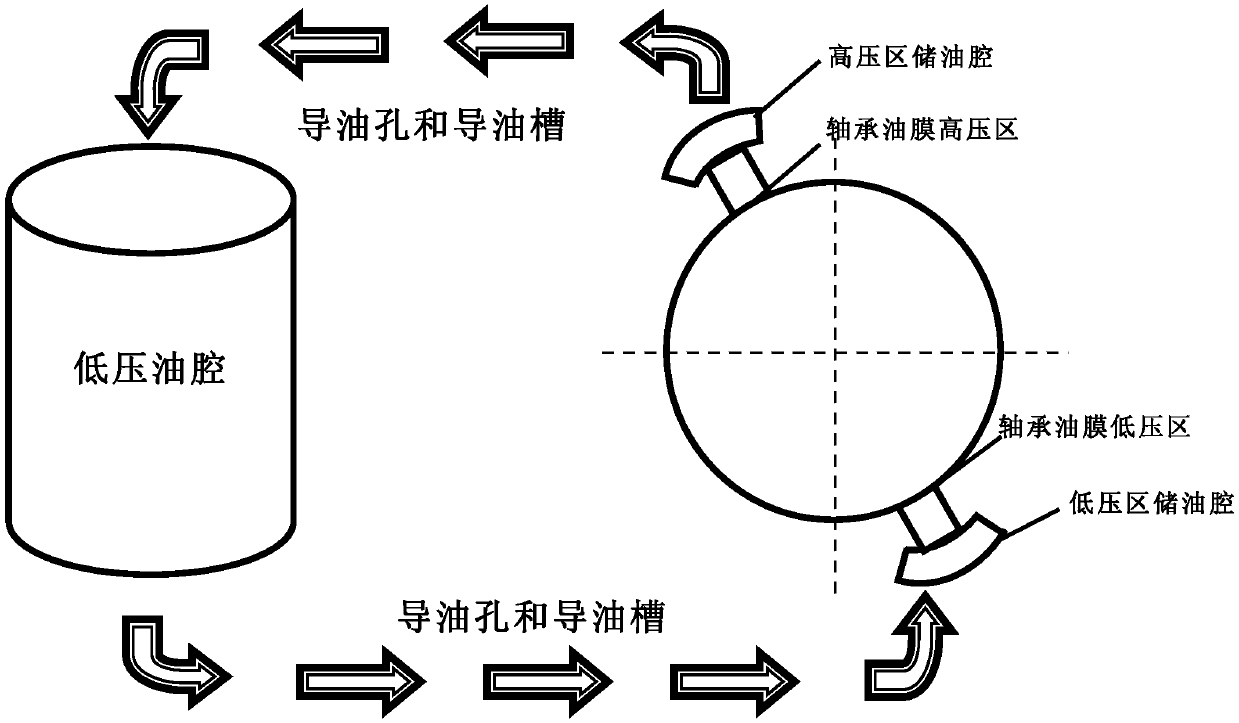

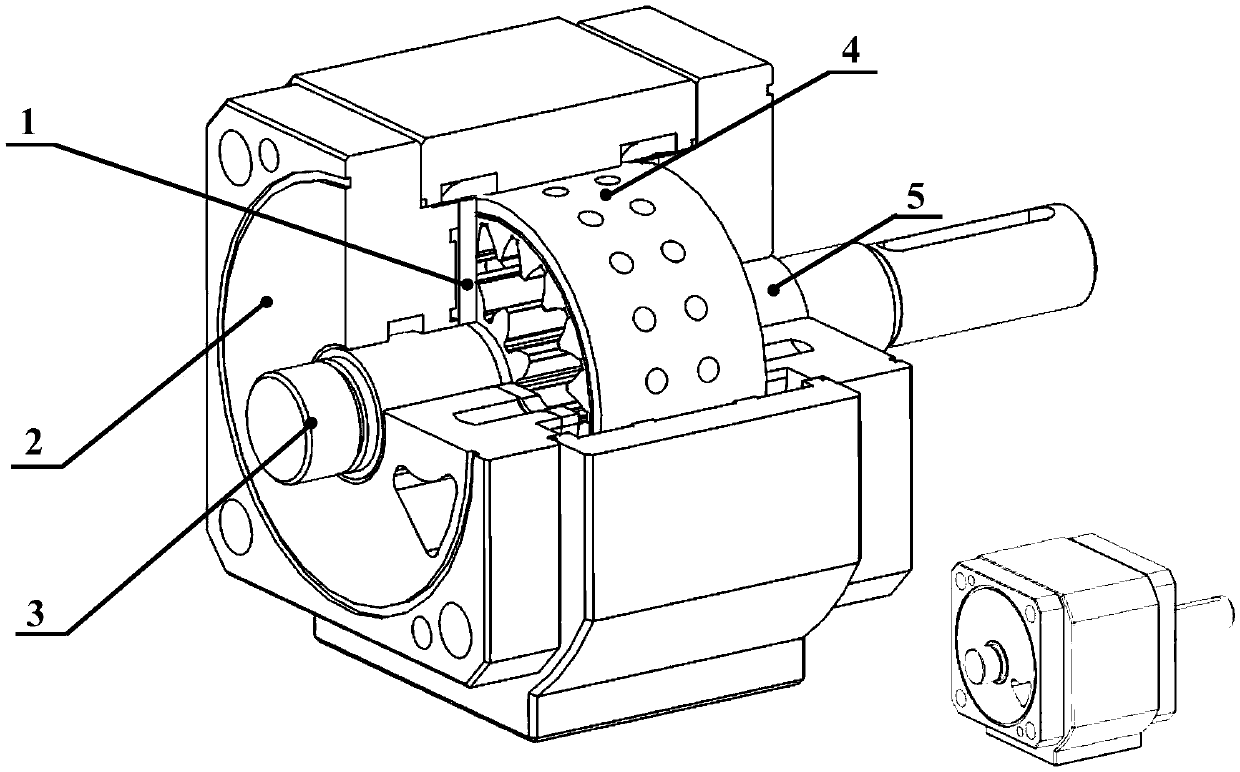

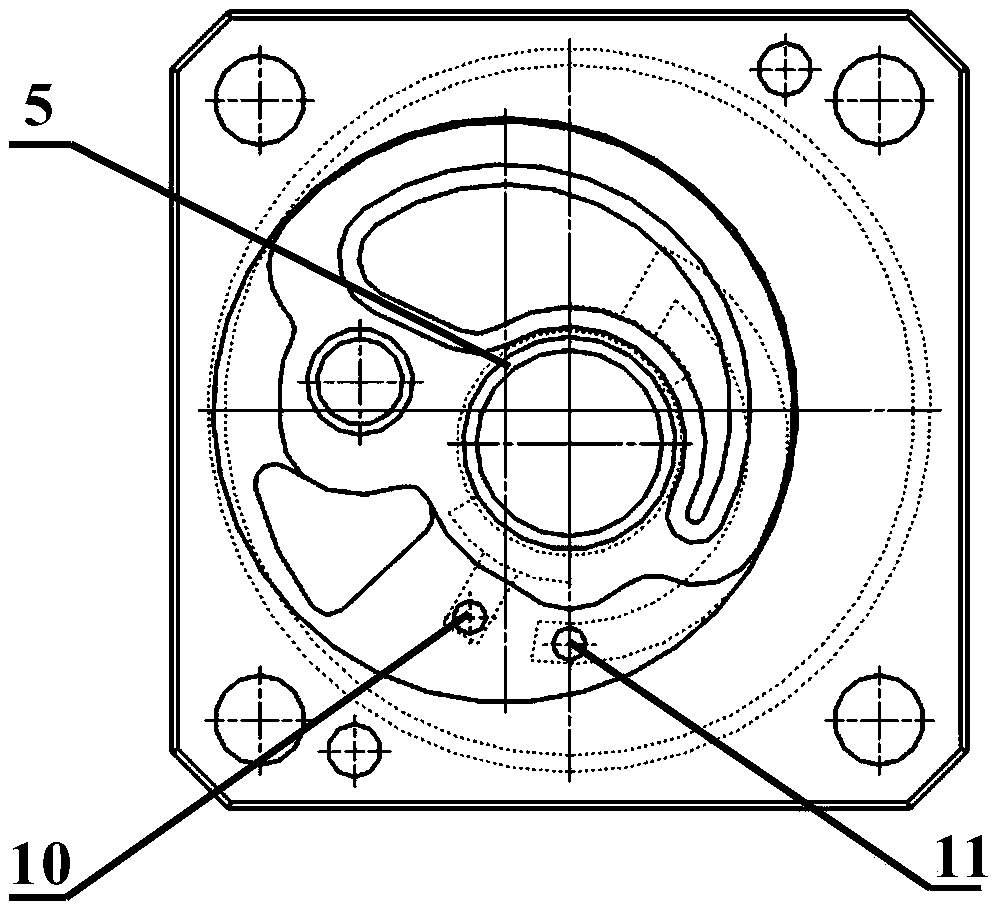

[0019] The sliding bearing self-circulating cooling oil lubrication system for the meshing gear pump of the present invention includes a sliding bearing 5 and a bearing seat 2, and there is a sliding bearing oil film between the journal of the meshing gear pump and the sliding bearing 5, and the sliding bearing oil film mainly plays a bearing role. The oil film of the sliding bearing will generate a high and low pressure area at the corresponding position. The pressure in the high pressure area is much higher than the atmospheric pressure, and the pressure in the low pressure area is generally lower than the atmospheric pressure. The low pressure oil chamber 14 of the gear pump communicates with the oil inlet 15 of the gear pump, and the pressure is generally close to the atmospheric pressure. The sliding bearing 5 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com