Downhole High Efficiency Screw Drilling Tools

A kind of screw drilling tool and high-efficiency technology, which is used in the drilling drive device, drilling equipment, earth-moving drilling and other directions in the wellbore, which can solve the problem of the reduction of the concentricity between the radial centering bearing and the metal rolling bearing group, and the poor centering effect of the radial centering bearing. , the complex shape of the conjugate meshing surface, etc., to overcome the interference effect and tooth distortion, stable operation, reduce water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

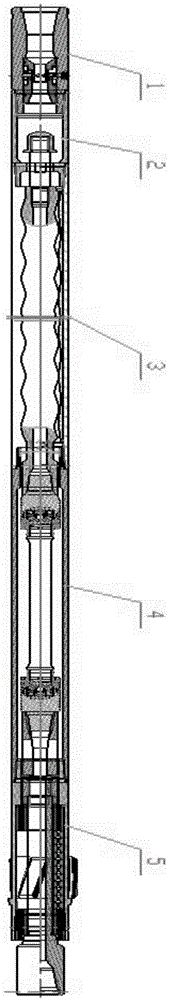

[0040] The high-efficiency downhole screw drilling tool of the present invention comprises a bypass valve assembly 1, an anti-drop joint 2, a motor joint 3, a universal joint assembly 4 and a bearing joint assembly 5 connected sequentially from top to bottom,

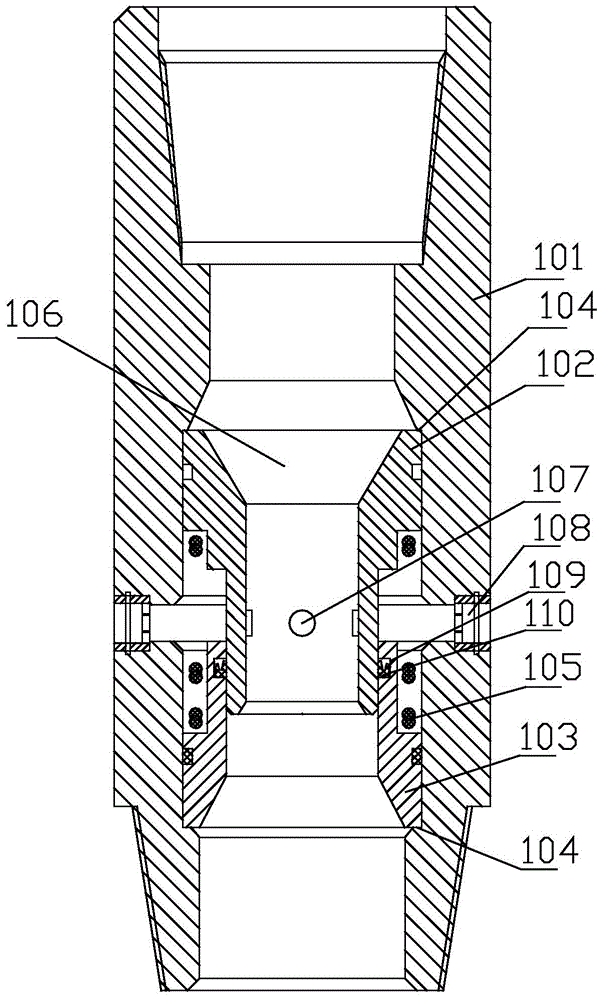

[0041] The bypass valve assembly 1 includes a cylindrical valve body 101. A valve core 102 and a valve seat 103 are installed in the inner cavity of the valve body 101. Both the valve seat 103 and the valve core 102 are cylindrical, and the valve seat 103 is sleeved on the valve core. 102, the bottom of the valve seat 103 is against the shoulder 104 provided at the lower part of the inner cavity of the valve body 101, the valve core 102 can slide up and down in the valve body 101, and a spring 105 is installed between the valve core 102 and the valve seat 103, and the spring 105 The top of the spool 102 can be pressed against the shoulder 104 provided on the upper part of the inner cavity of the valve body 101, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com