Wear-resistant strip welding structure and method for titanium alloy drill pipe joint

A technology of drill pipe joints and titanium alloys, which is applied in the direction of drill pipes, drill pipes, earthwork drilling, etc., can solve problems such as wear and failure of titanium alloy drill pipe joints, achieve reliable bonding strength, excellent wear resistance, and improve cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

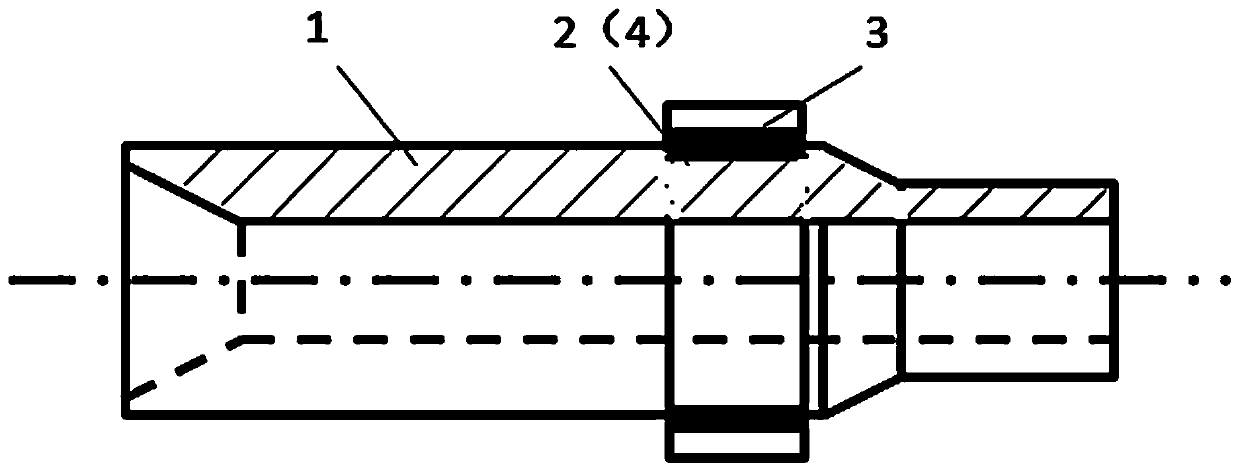

[0029] The material for titanium alloy drill pipe joint body 1 is TC4, its main material composition is Ti-6Al-4V, the outer diameter of the joint is 127mm, and the length of the joint is 279.4mm; the intermediate medium layer 2 is nickel-based alloy; the wear-resistant material layer 3 For high chromium alloy.

[0030] Concrete welding method of the present invention is as follows:

[0031] First, a ring groove with a width of 76 mm and a depth of 1.2 mm is machined on the surface of the drill pipe joint body 1 made of titanium alloy, and nickel-based alloy powder is covered on the surface of the groove. Using a laser beam, melt the nickel-based alloy powder and the material of the surface layer of the titanium alloy joint at 1680°C, cool slowly to 930°C and then hold for 0.5h, then furnace cool to 600°C for 1h and then air cool.

[0032] After testing, the intermediate dense layer 4 formed after melting the nickel-based alloy powder has no cracks and has a thickness of 1.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com