Hydraulic vane pump

A vane pump, hydraulic technology, applied in the field of hydraulic pumps, can solve the problems of stator wear performance, insufficient effective pressure, unreliable work, etc., to achieve good working life, reduce system configuration costs, and avoid wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

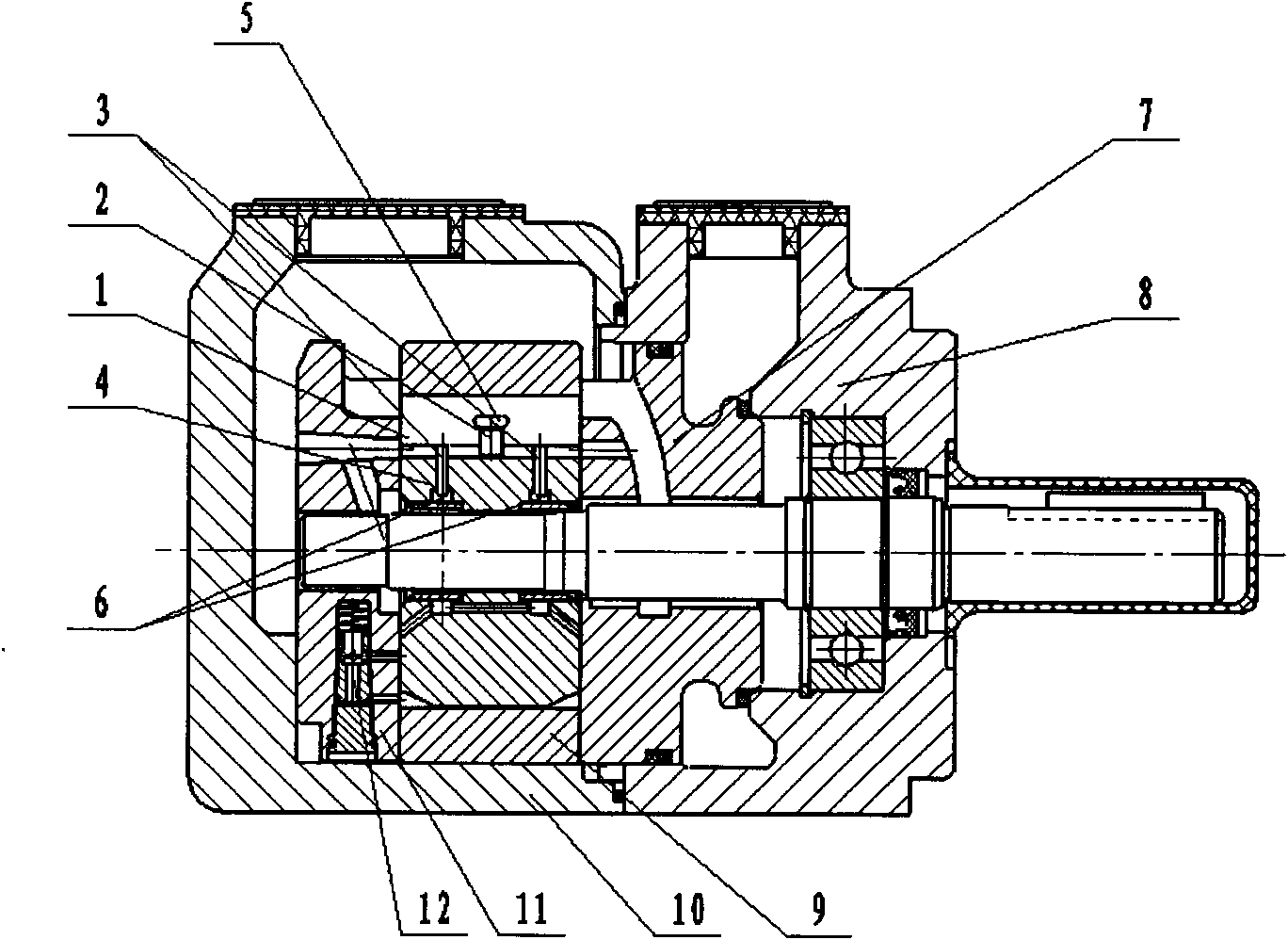

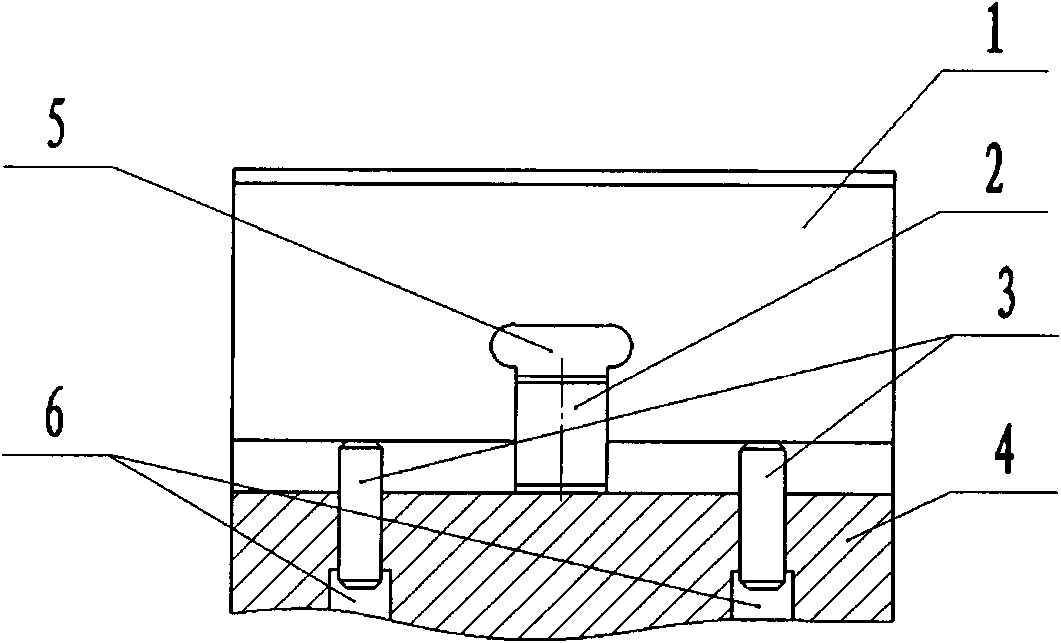

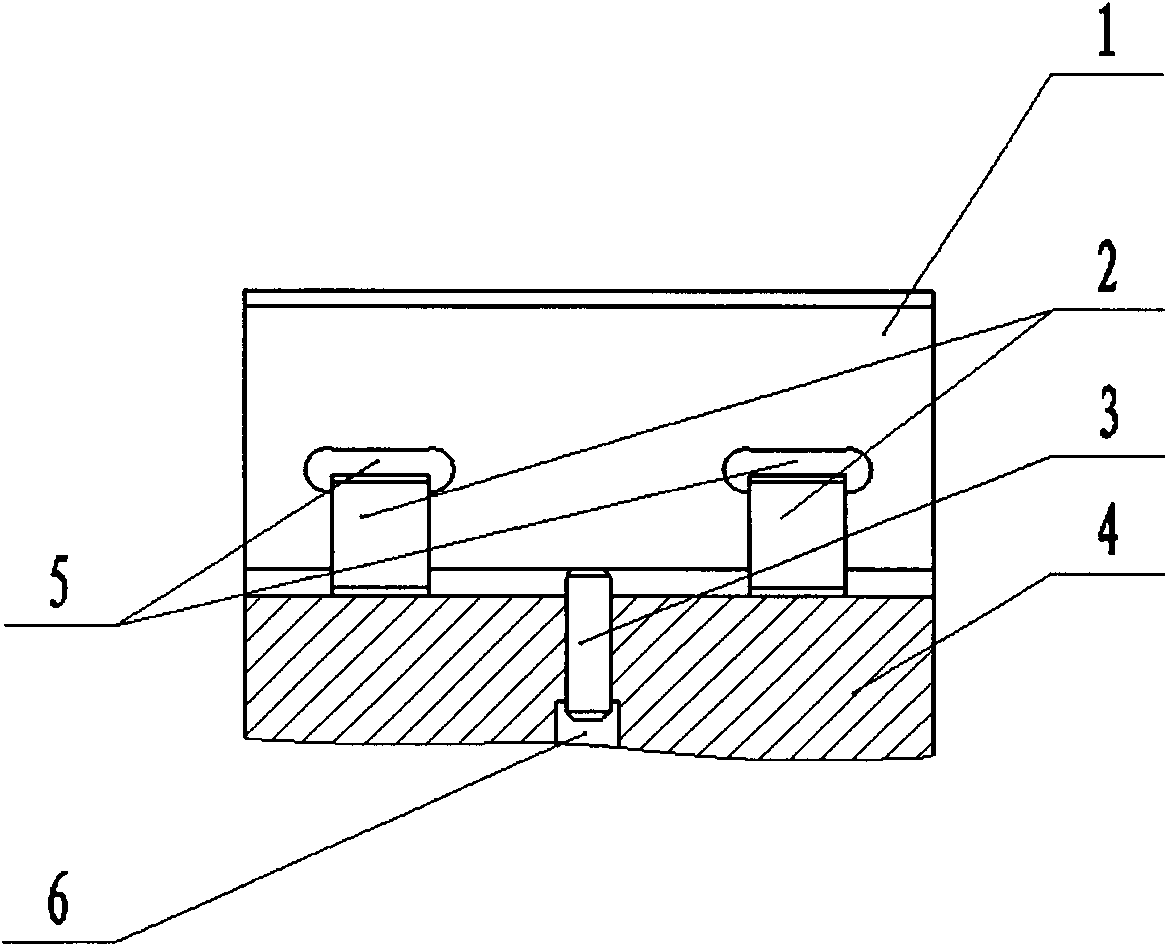

[0031]The hydraulic vane pump of the present invention includes a pump body (including the left and right pump bodies) with a fluid inlet and outlet and an inner cavity, and a rotatable rotor with a plurality of rotor grooves distributed radially (including the integral rotor and the split rotor composed of two half rotors). , the stator placed outside the rotor, the side plates (including the left and right side plates) located at both ends of the rotor stator, the protruding and retractable blades located in each rotor slot, and one or more sub-blades installed at the lower part of each blade 1. One or more pins installed at the bottom of each rotor slot; two protruding adjacent blades form a pumping space with the inner surface of the stator, the outer circle of the rotor, and the two side plates. When the rotor rotates and the blades protrude When the volume of the pumping space expands and shrinks alternately to produce suction and discharge for the fluid, one or more volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com