A production method of steel for glass curtain wall pre-embedded fasteners

A technology of glass curtain wall and production method, which is applied in the direction of workpiece heating device, workpiece surface treatment equipment, manufacturing tools, etc., which can solve the problems of poor toughness, high production cost, and poor atmospheric corrosion resistance, so as to improve wear resistance and strength , Improve the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

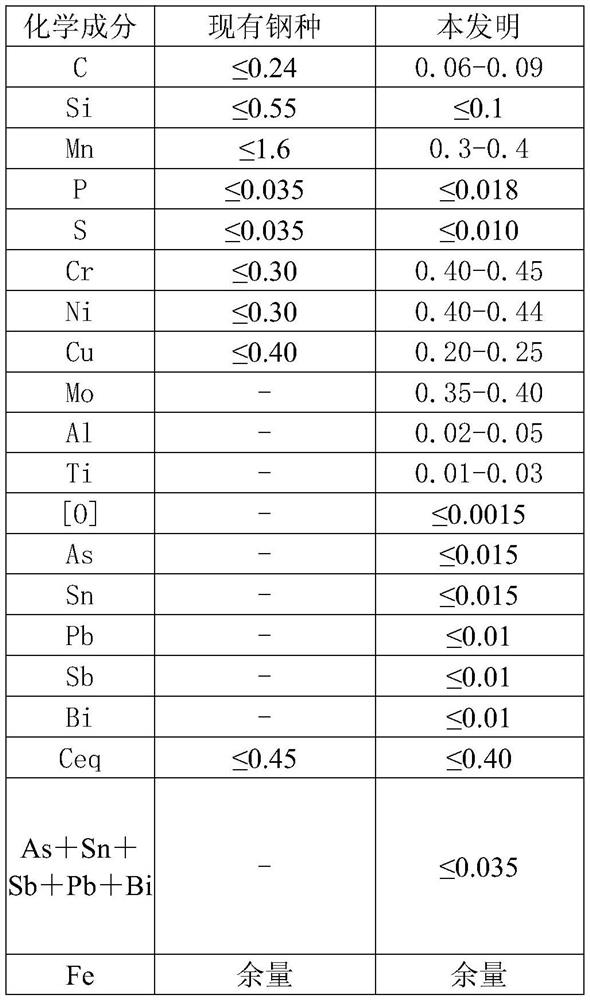

Method used

Image

Examples

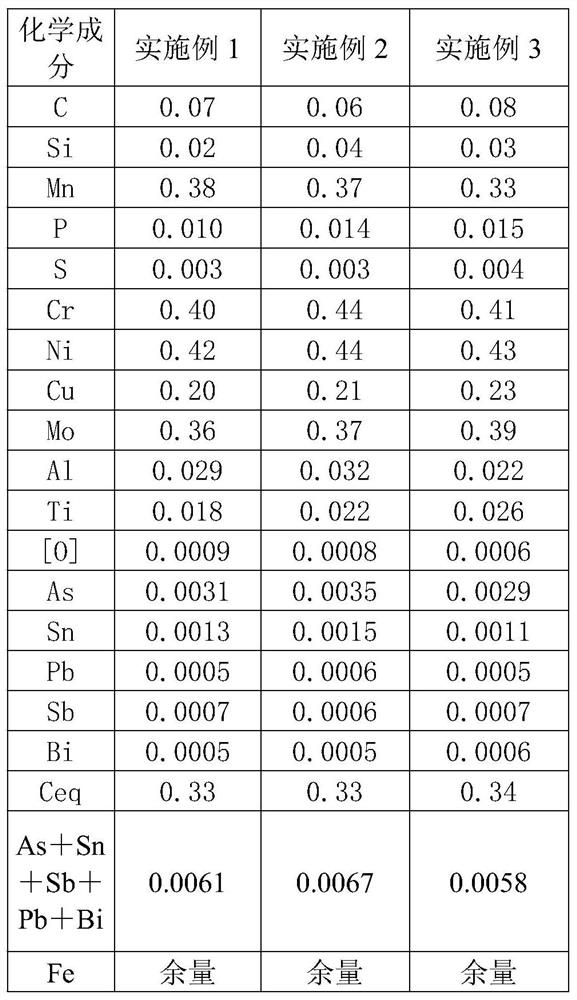

Embodiment 1~3

[0047] Prepared by the following production process:

[0048] (1) Hot metal pretreatment: adopt the KR desulfurization method, stir the hot metal in the ladle, stir continuously for 8-10 minutes, form a vortex, gradually put 450Kg~500Kg CaO+CaF2 mixed desulfurizer into the center of the vortex, and keep stirring the hot metal to desulfurize fully react with the sulfur in the molten iron, and then remove the slag by the slag remover to remove the desulfurization products, reduce the S content of the molten iron, and the slag removal rate reaches more than 90%, ensuring that the S of the molten iron after desulfurization is <0.005%;

[0049] (2) Converter smelting: Converter adopts peroxidation blowing, control tapping C ≤ 0.05%, first add deoxidizer aluminum cake according to tapping C, then use metal manganese, nickel plate, low carbon ferrochrome to adjust alloy content, and finally add Lime and low-titanium refining slag; ensure that the refining furnace C≤0.06%, Mn: 0.25%-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com