Anti-leakage well flushing packer

A well-washing packer and leak-proof technology, which is applied in the direction of flushing wellbore, sealing/isolation, wellbore/well parts, etc., can solve the problem that the well-washing packer has not been popularized and applied, the ball seat cannot be opened, and the increase To improve the economic benefits of oil field development, avoid the wear and tear failure of the cup, and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

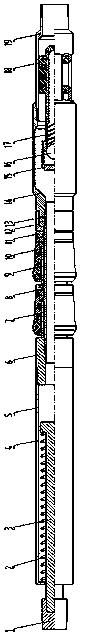

[0017] according to figure 1 As shown, the anti-leakage washout packer includes an upper joint 1, an upper shell 4, a central pipe 10, a lower shell 14, and a lower joint 19 connected sequentially from top to bottom, and a leather cup is arranged on the outside of the central pipe Assemblies, the cylinder composed of the lower shell and the lower joint is provided with a one-way switch valve inside, the side wall of the upper shell is provided with an overflow hole 5 connected to the central pipe, and the side wall of the lower shell is opened at the same time The suction port communicates with the center pipe and the one-way switch valve. The one-way switch valve includes a sub-fluid 18, a valve cover 15, a stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com