Major diameter soil-pressure balance shield machine full stratum cutter

A technology of earth pressure balance and shield machine, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., which can solve the problem of the service life of the cutter head, and achieve the effects of improving service life, good wear resistance, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

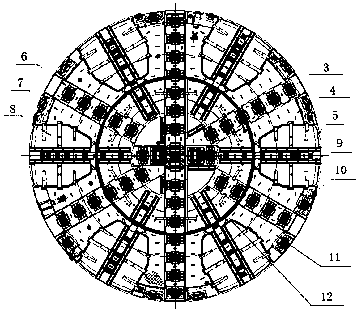

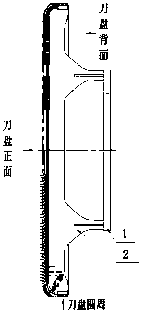

[0021] Such as figure 1 , 2 As shown, the present invention provides a large-diameter earth pressure balance shield machine full formation cutter head, including a cutter head flange 1, a leg structure 2, a cutter head center 3, a cutter head periphery 4, a cutter head outer ring 5, The cutterhead spokes 6, the cutterhead panel 7, the opening area 8, the cutterhead flange 1 is arranged on the back of the cutterhead, the cutterhead flange 1 is connected to the power structure, the cutterhead flange 1 supports the cutterhead through the outrigger structure 2 and transmits torque , the cutterhead spokes 6 form the skeleton of the cutterhead and are used to install knives. There are twelve cutterhead spokes 6 in total, six main spokes and six auxiliary spokes. Different knives are assembled on the main sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com