Hydraulic jet sectional temporary plugging infinite stage fracturing method

A hydraulic jet, infinite-level technology, used in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of packer wear failure, formation fracturing failure at the casing sliding sleeve, etc. Oil and gas seepage channel, improve work efficiency and operation success rate, avoid the effect of opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

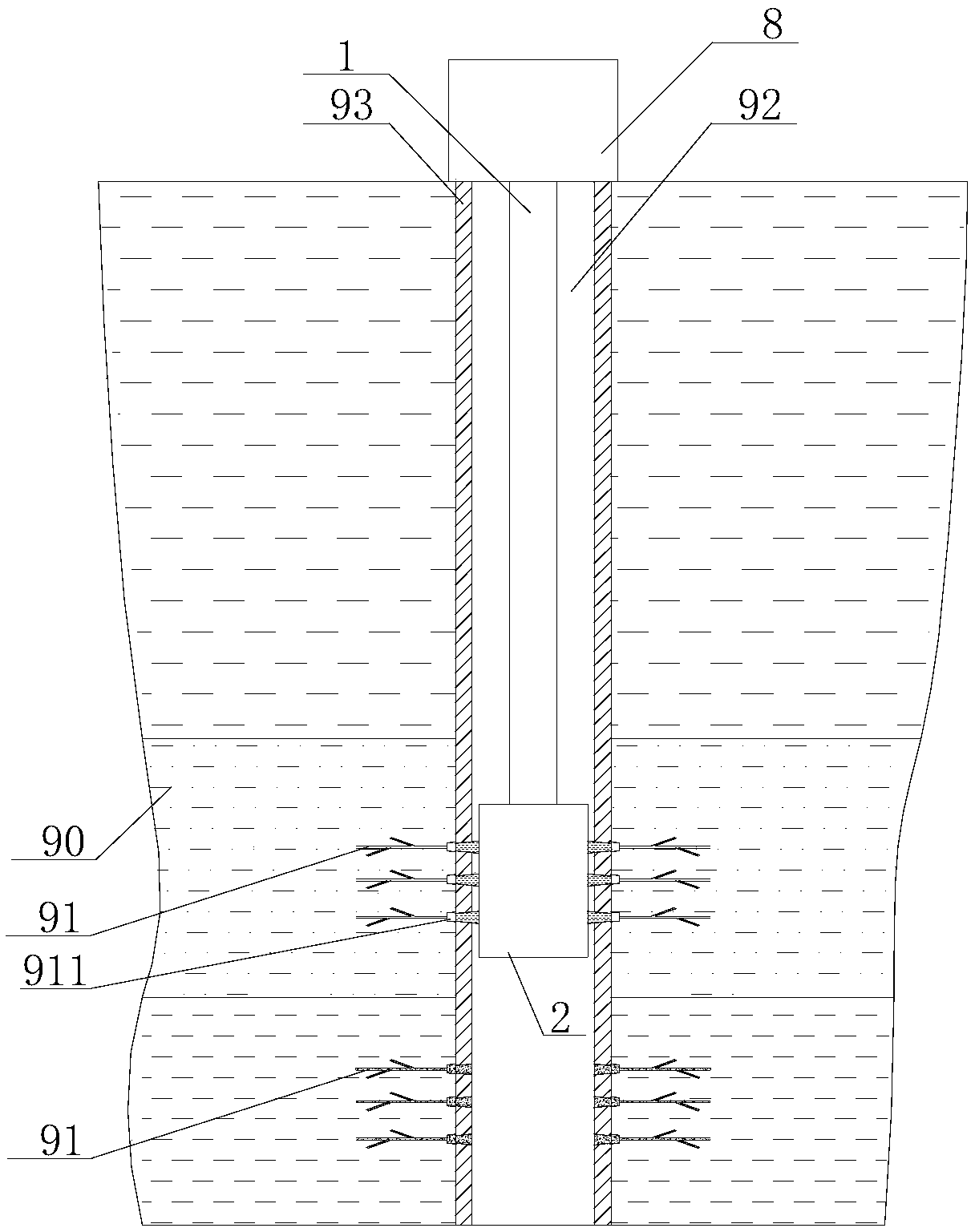

[0030] The present invention provides a hydraulic jet fracturing method for segmental temporary plugging and unlimited stages. In the method, a coiled tubing 1 is used to lower a downhole tool 2 to a predetermined position in a wellbore, and hydraulic jet fracturing reforms the aforementioned reservoir 90 at the predetermined position. Formation fractures 91, such as figure 1 As shown in Fig. 1, keep the position of the coiled tubing 1 and the downhole tool 2, pump the plugging fluid mixed with the temporary plugging agent from the wellhead 8, and temporarily plug the formation fractures; lift the coiled tubing 1 to make the downhole tool 2 reach multiple holes in the wellbore in sequence For the location where fracturing is requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com