Water passing device and maintenance method thereof

A water-through and water-through hole technology, which is applied in the direction of earthwork drilling and cutting machinery, etc., can solve the problems of coal mining in violation of safety regulations, inconvenient maintenance, and inconvenient maintenance, so as to improve reliability, facilitate cleaning, improve The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

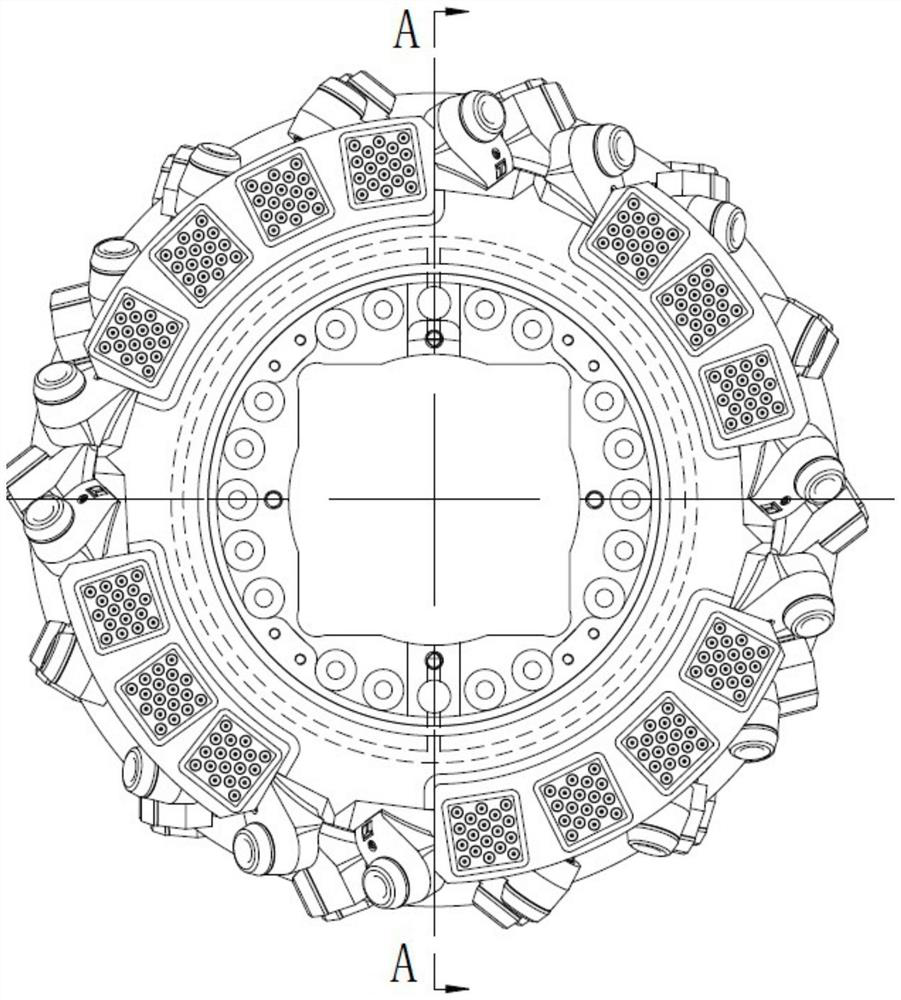

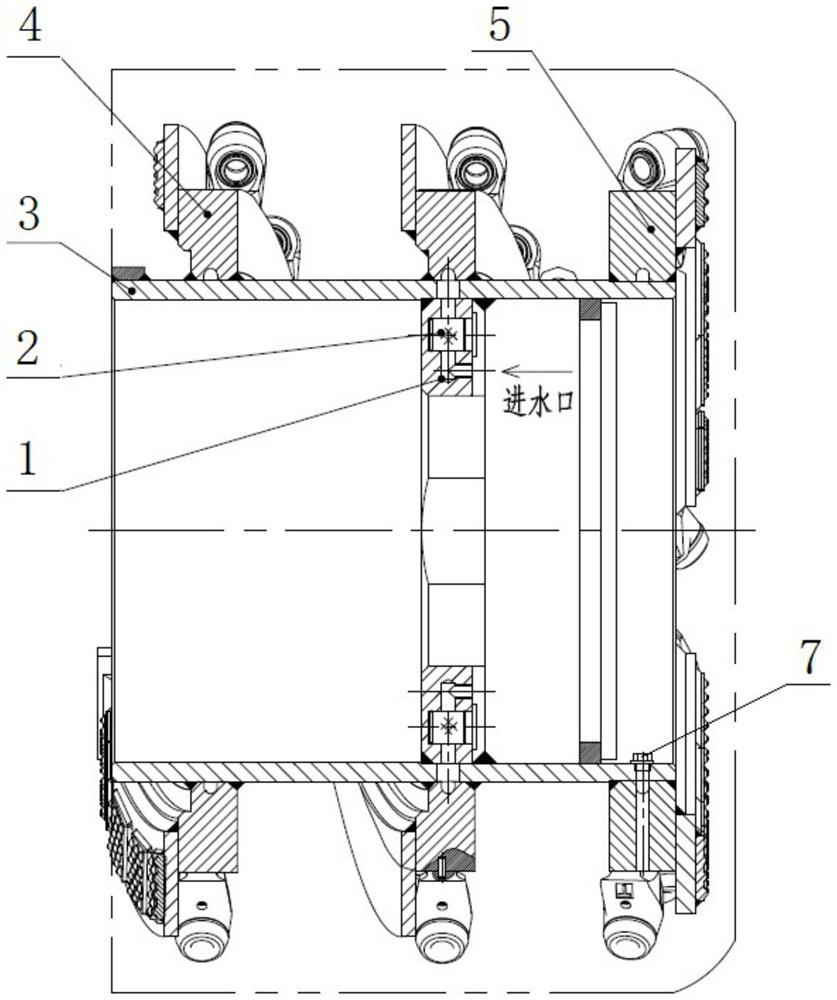

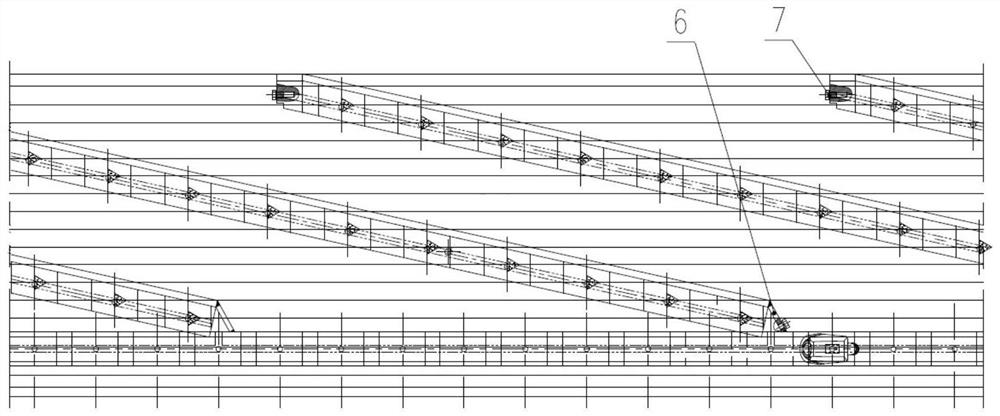

[0031] The invention discloses a water passing device, such as Figure 1-7 As shown, it includes a cylinder ring 3, a number of blades 4 spirally wound on the outer cylindrical surface of the cylinder ring and fixed by welding, and an end plate 5 welded and fixed on one end of the outer cylinder surface of the cylinder ring. A circle of water passage holes 3-1 on the end disk of the cylinder ring and a plurality of water passage holes 3-2 on the cylinder connection disk scattered in the circumferential direction are arranged on the cylinder ring along the circumferential direction. The water passage hole of the end plate of the cylinder ring is close to the end of the cylinder ring, and the axial direction corresponds to the position where the end plate is installed on the cylinder ring. The position of the water passage hole of the cylinder ring connecting plate in the axial direction corresponds to the position of the fixed connecting plate inside the cylinder ring. The rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com