Scroll compression mechanism and scroll compressor

A compression mechanism and scroll technology, applied in the field of scroll compressors, can solve problems such as scroll compression mechanism wear and failure, and achieve the effect of preventing wear and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following descriptions of various embodiments of the present disclosure are merely exemplary, and by no means limit the present disclosure and its application or usage. The same reference numerals are used to denote the same components in the respective drawings, and thus the configurations of the same components will not be described repeatedly.

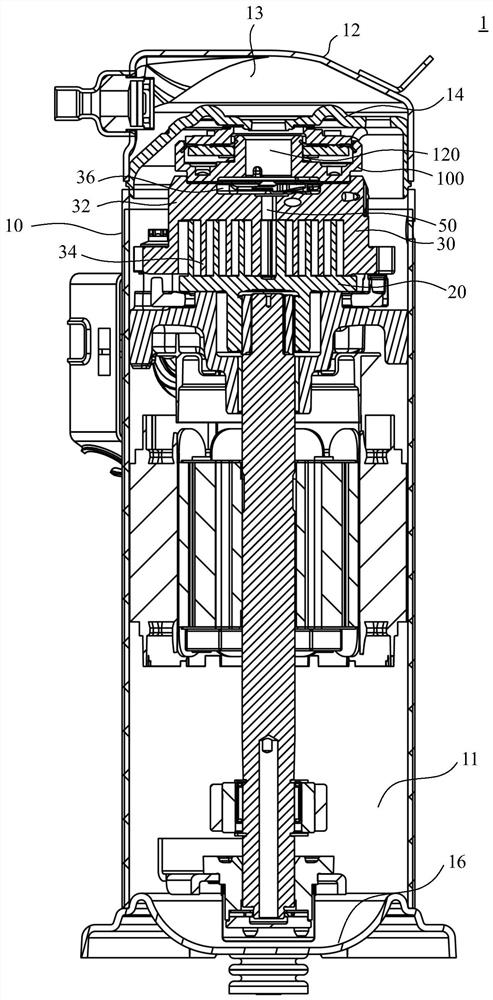

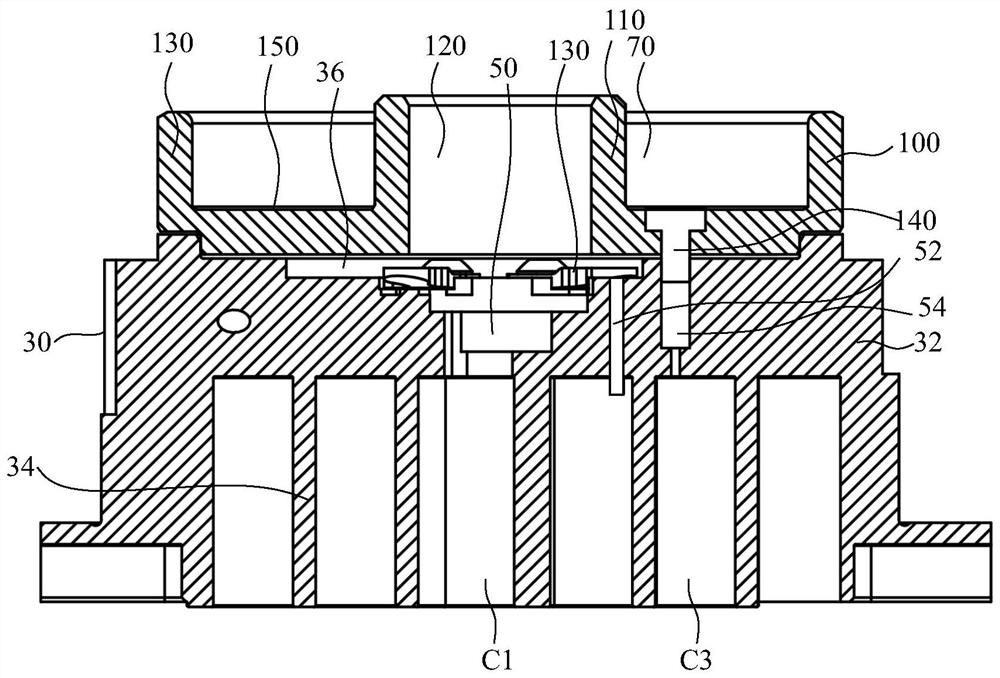

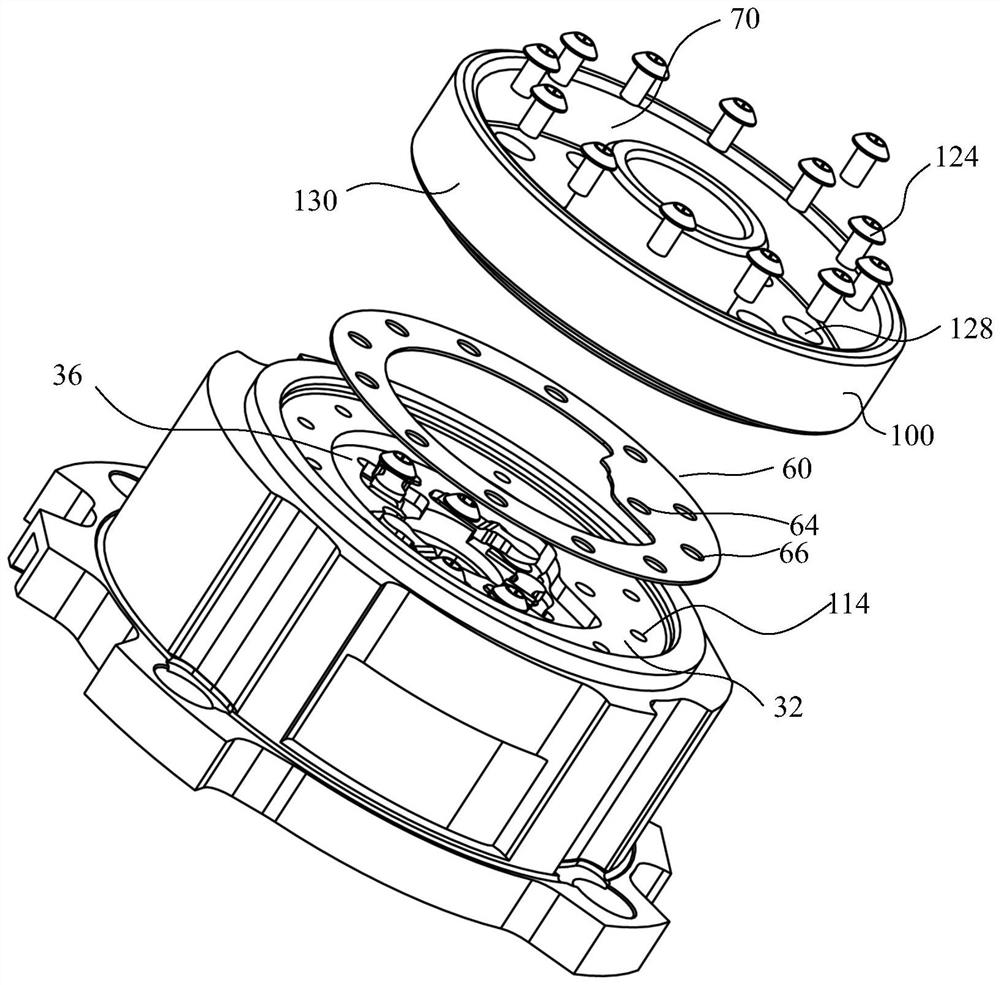

[0030] The following will refer to Figure 1-3 A compressor with a variable volume ratio function according to a comparative example will be described, in which, figure 1 is a sectional view schematically showing a compressor according to a comparative example; figure 2 is a sectional view schematically showing a fixed scroll assembly of a compressor according to a comparative example; and image 3 is an exploded perspective view schematically showing a fixed scroll assembly of a compressor according to a comparative example.

[0031] Such as figure 1 As shown, scroll compressor 1 includes a generally closed housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com