Gas pulse generator

A gas pulse and shell technology, which is used in fluid pressure actuation devices, devices affecting weather conditions, fluid pressure actuation system components, etc. The effect of reducing failure problems, reducing heat generation, and excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, but the scope of the present invention is not limited to the specific embodiments described.

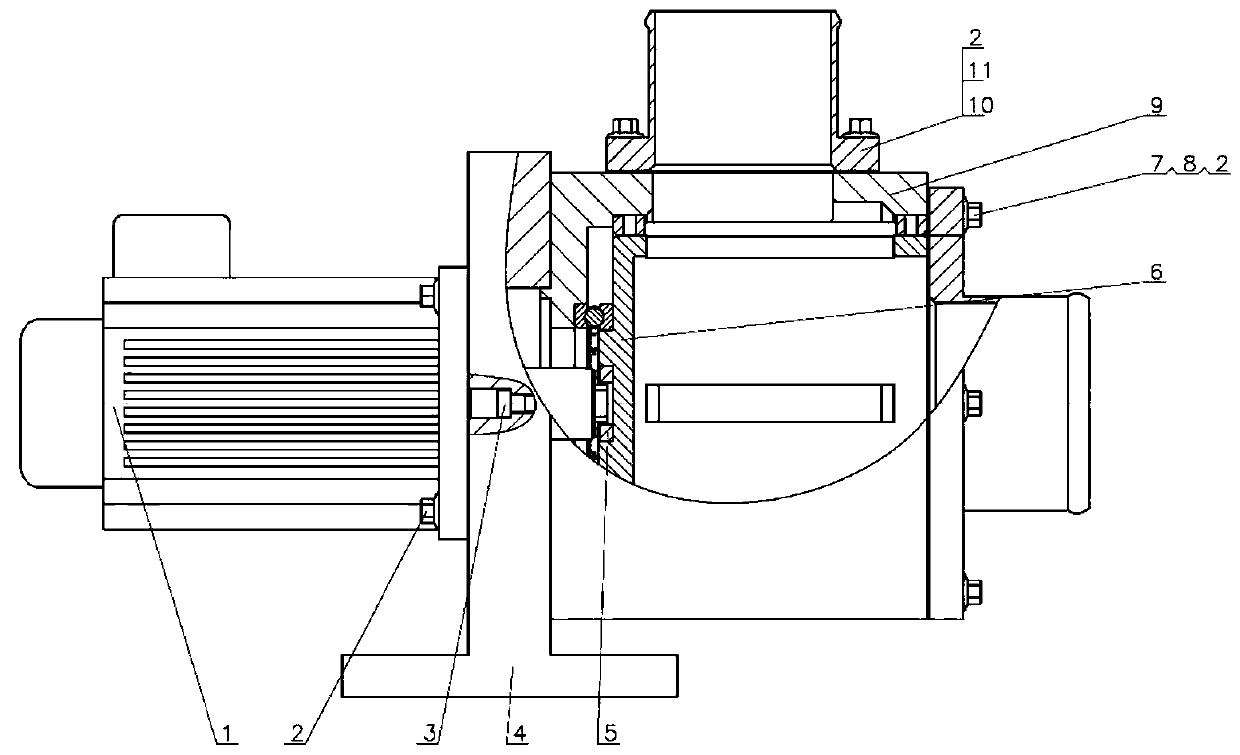

[0038] figure 1 is a schematic structural view of the gas pulsator according to the present invention. Such as figure 1 As shown, the structure of the gas pulser of the present invention includes: motor assembly 1; fastening bolt 2; housing fastening bolt 3; bracket 4; rotor connecting plate 5; rotor assembly 6; ; Inlet end cover 8; Shell assembly 9; Outlet end cover oil-resistant paper pad 10; Outlet end cover 11, etc.

[0039] The motor assembly 1 may include a DC servo motor, which is used to drive the rotor in the casing of the gas pulse generating part of the gas pulser to rotate. The casing fastening bolts 3 are used to fasten the casing of the gas pulse generating part of the gas pulser on the bracket (or support frame) 4 . The bracket (or support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com