Blast furnace compaction type vertical stock rod drum shaft composite sealing device

A composite sealing and compact technology, which is applied in inspection devices, engine seals, engine components, etc., can solve problems such as normal maintenance of blast furnaces and hidden dangers in safe production, leakage of blast furnace gas, and rapid aging of sealing components, etc., to eliminate blast furnaces Normal maintenance and hidden dangers of safe production, prevention of blast furnace gas leakage, and improvement of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

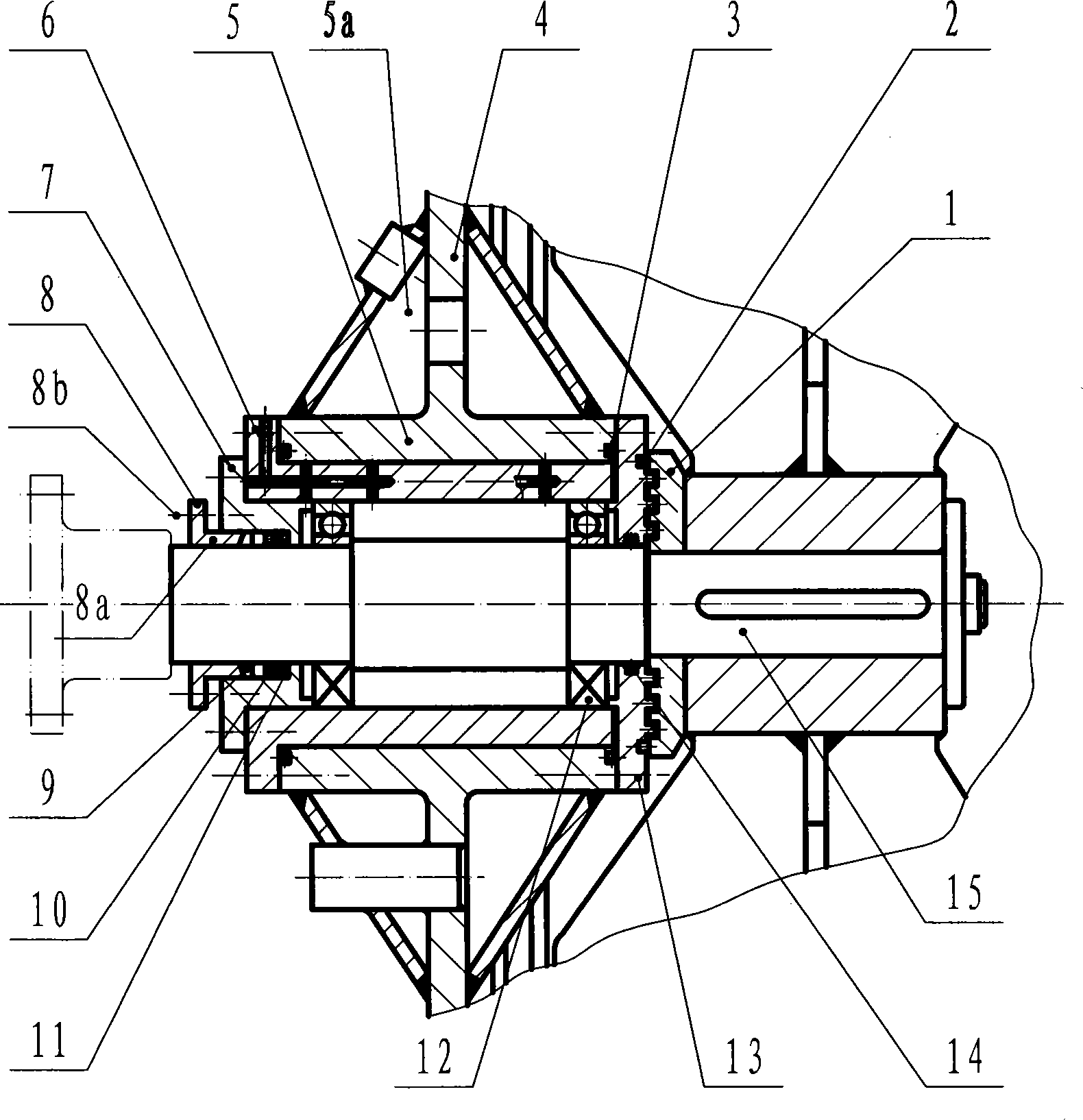

[0013] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0014] The blast furnace compact vertical probe drum shaft composite sealing device is placed between the two ends of the drum shaft 15 and the bearing seat 4 . One end of the reel shaft 15 is the high temperature side, and the other end of the coupling is the low temperature side, wherein:

[0015] The high temperature side of the mandrel shaft 15 includes three seals, that is, the first seal consisting of the sealing cover 1, the gland 13 and the packing ring 2 woven with a flexible graphite packing ring with high temperature resistance and dustproof effect, The second mechanical labyrinth seal composed of the sealing cover 1 and the gland 13, and the third seal formed by setting the silicone rubber O-ring 14 between the gland 13 and the reel shaft 15.

[0016] The low temperature side of the reel shaft 15 adopts a pre-tightened seal, which is composed of a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com