Double-stack three-dimensional memory and manufacturing method thereof

A manufacturing method and memory technology, applied in semiconductor devices, electrical solid state devices, electrical components, etc., can solve the problems of increased aspect ratio of 3D memory cells, manufacturing complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

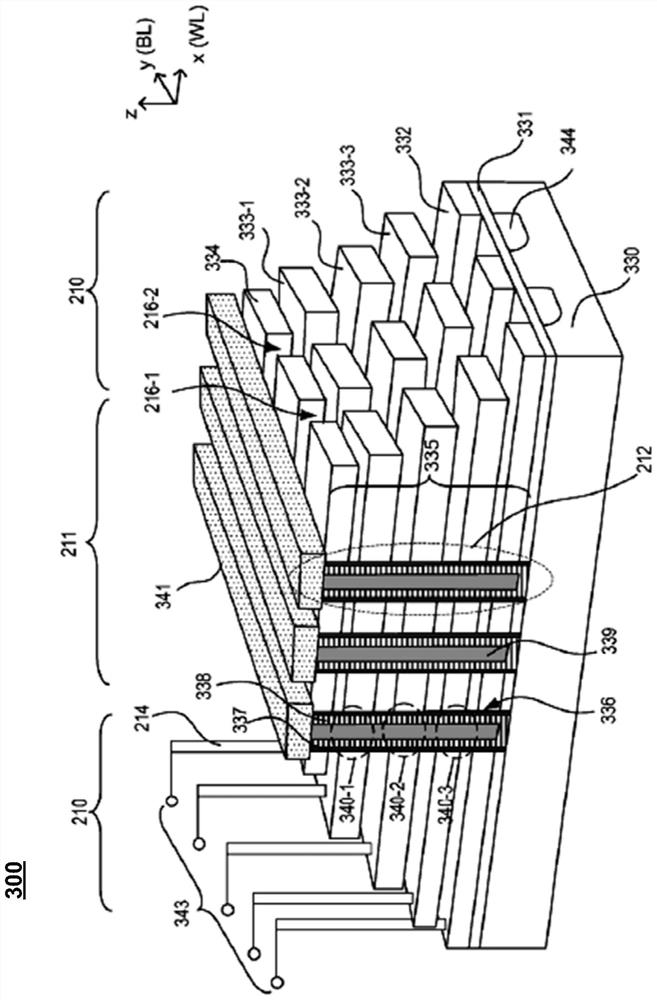

[0015] While specific configurations and arrangements are discussed, it should be understood that this is done for illustration purposes only. A person skilled in the relevant art will recognize that other configurations and arrangements may be used without departing from the spirit and scope of the present disclosure. It will be apparent to those skilled in the relevant art that the present disclosure may also be used in various other applications.

[0016] It should be noted that although references in the specification to "one embodiment," "an embodiment," "exemplary embodiment," "some embodiments," etc. indicate that the described embodiments may include a particular feature, structure, or characteristics, but each embodiment may not necessarily include that particular feature, structure or characteristic. Moreover, such phrases are not necessarily referring to the same embodiment. Furthermore, when a particular feature, structure or characteristic is described in conjun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com