Automatic leveling inkjet device

An inkjet device and automatic leveling technology, which is applied in printing and other directions, can solve problems such as inapplicability, and achieve the effect of suppressing lateral vibration and stabilizing automatic leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

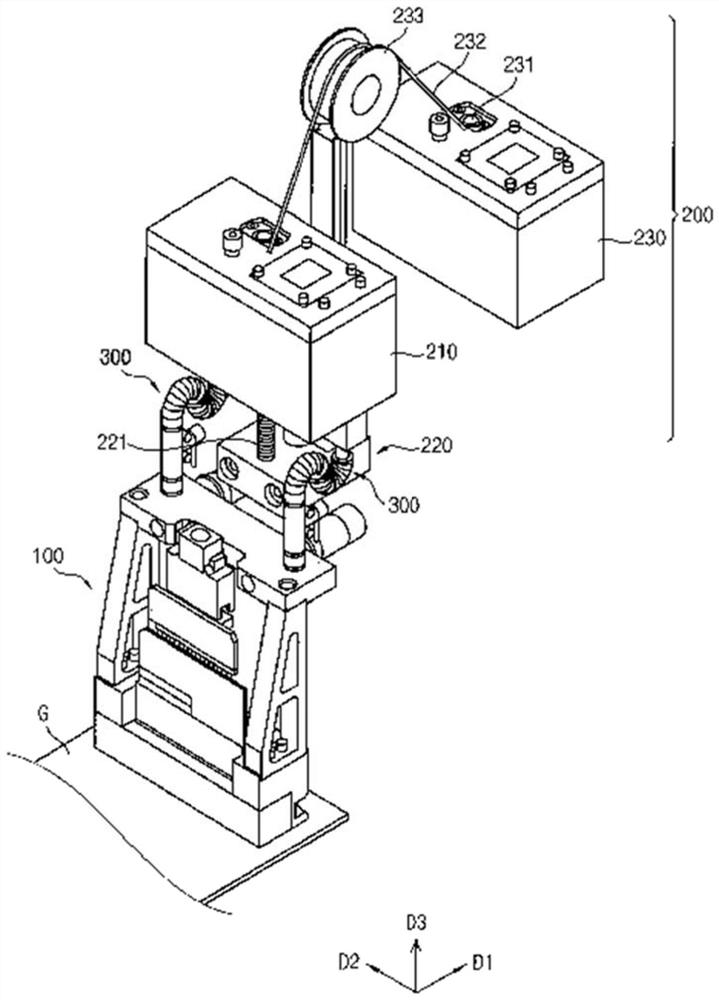

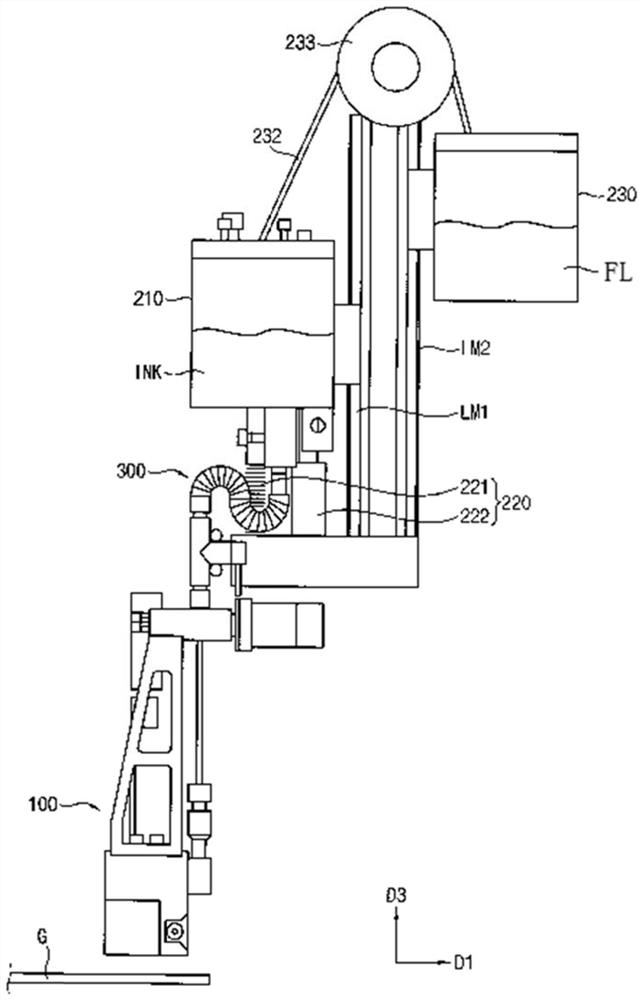

[0041] figure 1 It is a perspective view of a self-leveling inkjet device according to an embodiment of the present invention. figure 2 yes figure 1 Side view of the self-leveling inkjet device.

[0042] refer to figure 1 as well as figure 2 , the self-leveling inkjet device may include an inkjet head unit 100 , an ink level maintaining unit 200 and a connection unit 300 .

[0043] The inkjet head unit 100 ejects ink droplets toward a printing object G (for example, a substrate) (see Figure 4 I), such as figure 1 as well as figure 2As shown, the inkjet head unit 100 involved in this embodiment may be a piezoelectric (piezo- electric) type inkjet head module. However, the scope of rights of the present invention is not limited thereto. If necessary, the inkjet head unit 100 may be a heat source that is heated by a therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com