Function setting method and device based on industrial control screen and industrial control screen

An industrial control and functional technology, which is applied in the direction of program control devices, program code conversion, digital data authentication, etc., can solve the problems of cumbersome function changes of industrial control screens, reduce the process of program editing, compiling and programming, avoid code programming, and facilitate functions The effect of the change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a function setting method based on an industrial control screen. Specifically, the industrial control screen may be an industrial touch screen. This method can realize the function setting of the industrial control panel relatively simply.

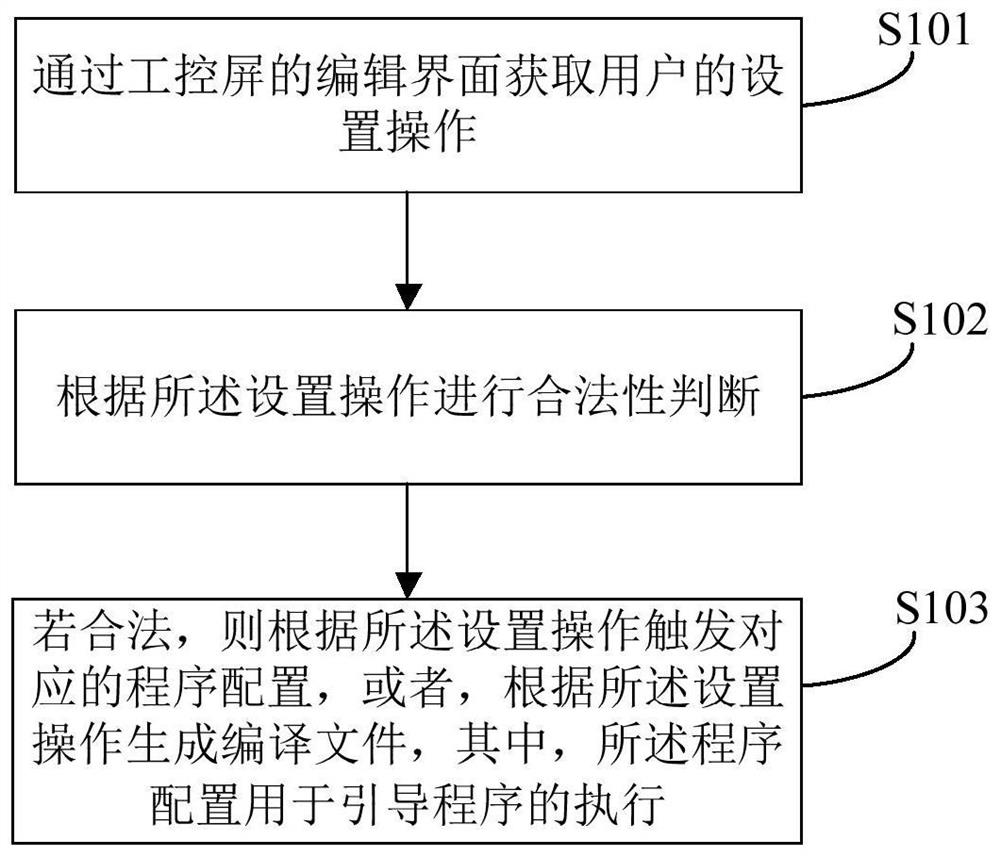

[0052] figure 1 It is a flow chart of the function setting method based on the industrial control screen provided by Embodiment 1 of the present invention, as shown in figure 1 As shown, the method includes the following steps:

[0053] S101. Obtain a user's setting operation through an editing interface of the industrial control screen.

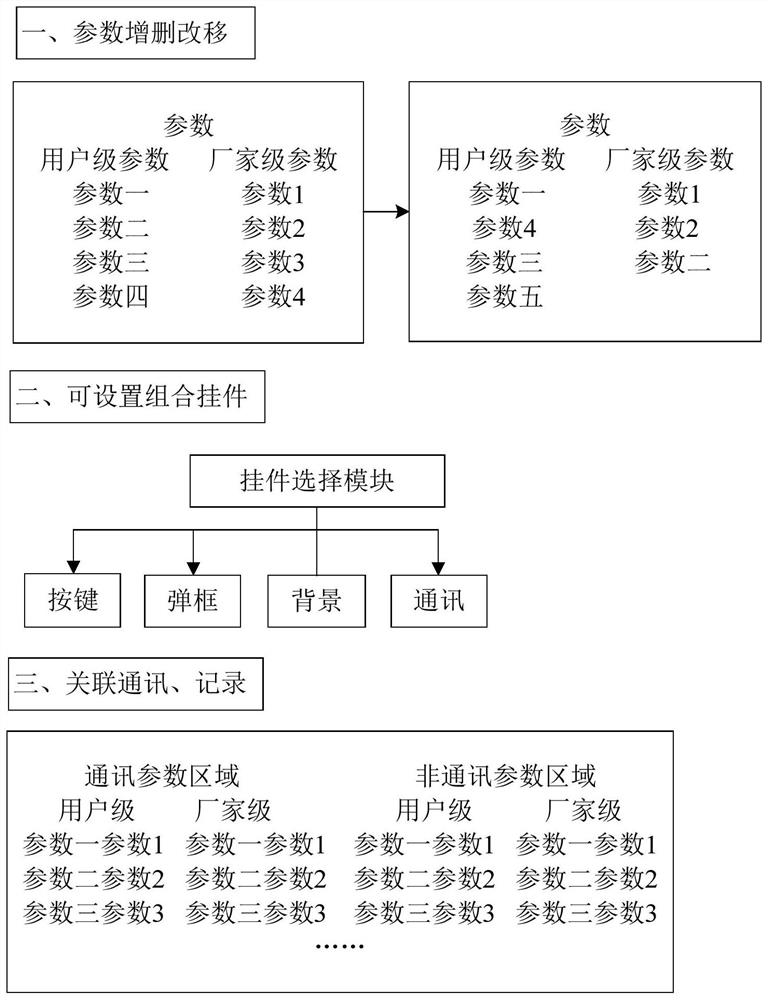

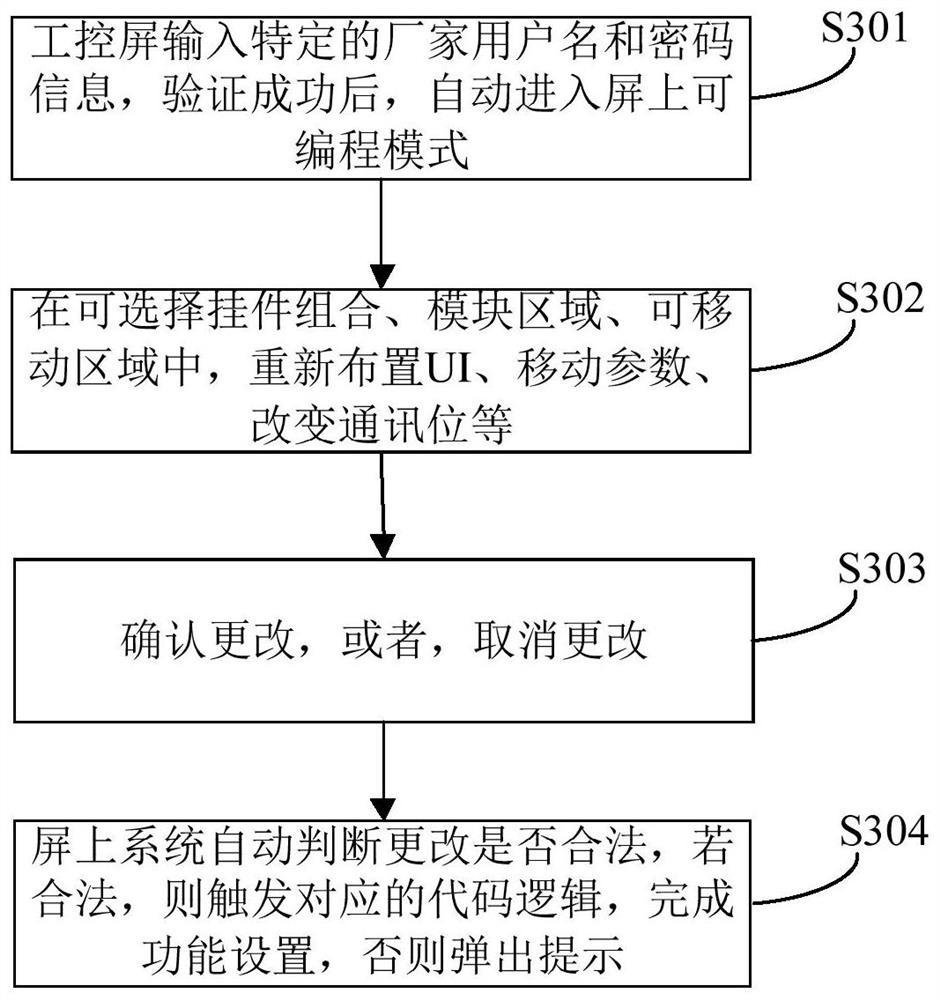

[0054] Wherein, the editing interface of the industrial control panel refers to the interface provided for the user to set the function. Through the editing interface, the user can set the function, and then realize the function setting without writing codes. Users can be manufacturers or after-sales personnel. The setting operation refers to the operation correspondi...

Embodiment 2

[0096] Based on the same inventive concept, this embodiment provides an industrial control panel-based function setting device, which can be used to implement the industrial control panel-based function setting method described in the above embodiments. The device can be realized by software and / or hardware, and the device can generally be integrated into an industrial control panel.

[0097] Figure 4 It is a structural block diagram of the function setting device based on the industrial control panel provided by the second embodiment of the present invention, as shown in Figure 4 As shown, the device includes:

[0098] The obtaining module 41 is used to obtain the user's setting operation through the editing interface of the industrial control screen;

[0099] Judging module 42, configured to judge legality according to the setting operation;

[0100] The setting module 43 is configured to trigger a corresponding program configuration according to the setting operation i...

Embodiment 3

[0123] This embodiment provides an industrial control panel, including: the function setting device based on the industrial control panel described in the above embodiments.

[0124] In this embodiment, the user's setting operation is obtained through the editing interface of the industrial control screen, and the legality is judged according to the setting operation. If it is legal, the corresponding program configuration is triggered according to the setting operation or a compiled file is generated according to the setting operation, so as to After completing the function setting, you can execute the program according to the program configuration or execute the compiled file to realize related functions when necessary. Regardless of whether the industrial control panel includes a compiler or not, there is no need to write code, which realizes function setting, reduces the process of program editing, compilation and programming, avoids tedious code programming, and realizes t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap