Banana combing platform based on rigid-flexible coupling parallel mechanism

A rigid-flexible coupling, drop-comb technology, applied in application, food processing, food science, etc., can solve the problems of poor adaptive envelope effect of banana cobs and low profiling fit, avoiding missed banana combs handles, effects that improve adaptive envelope performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

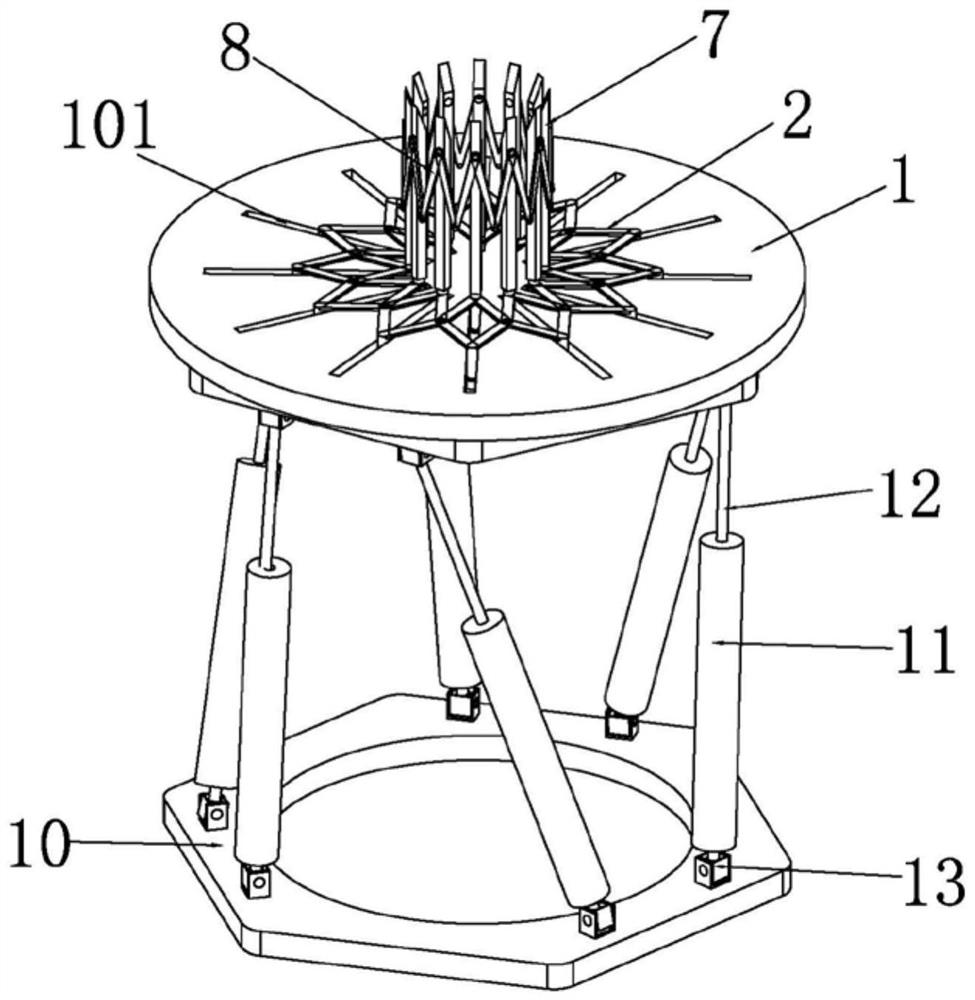

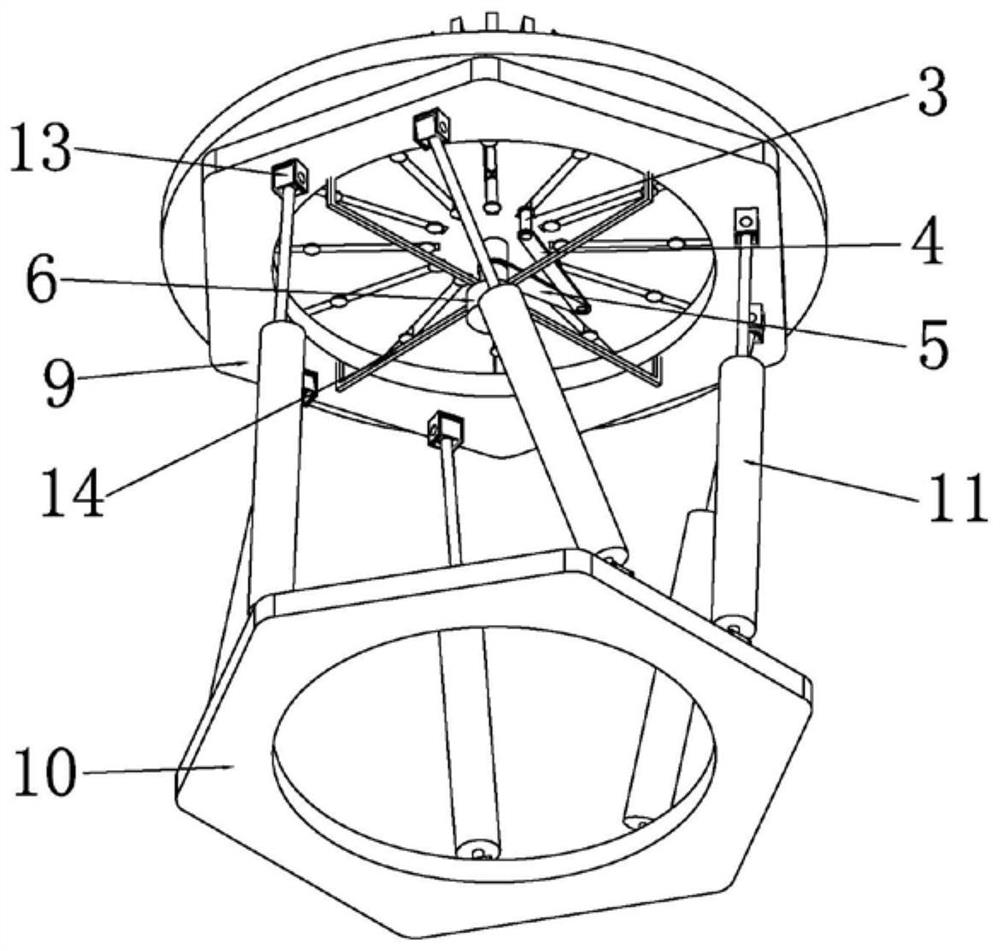

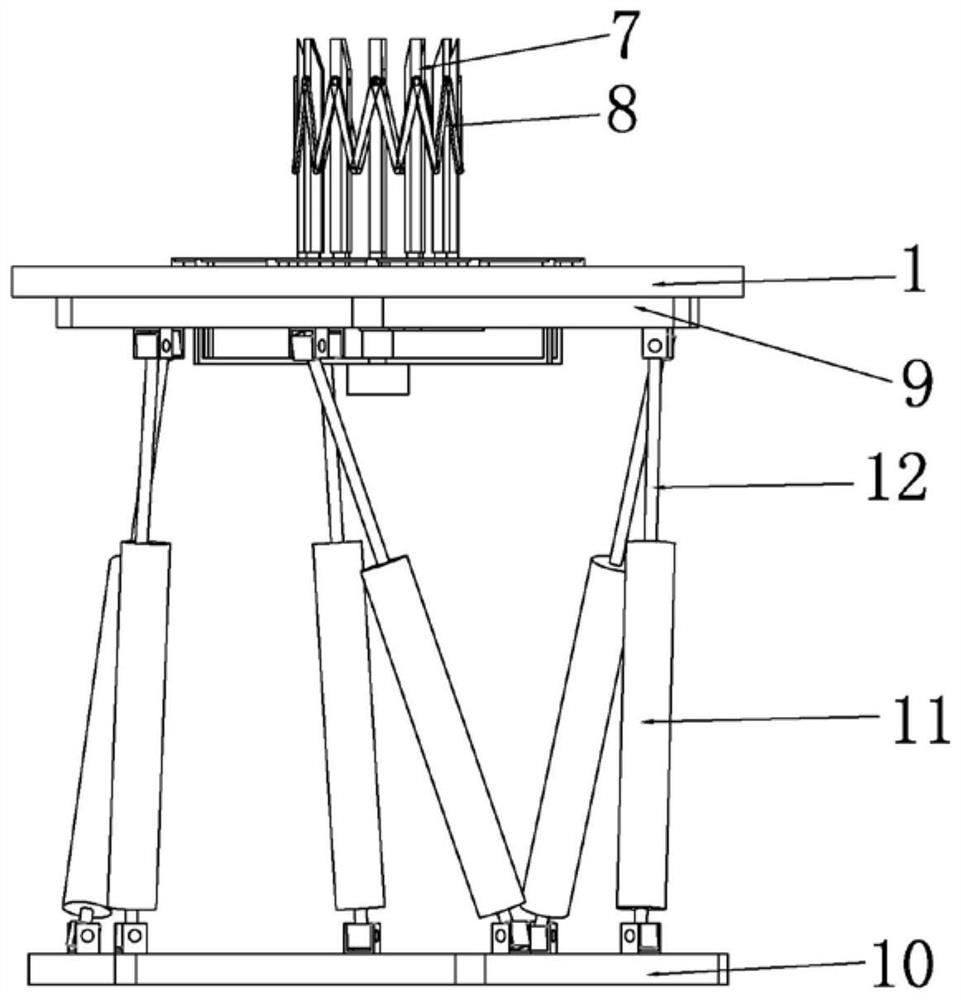

[0020] Such as Figure 1 to Figure 7 As shown, the banana combing platform based on the rigid-flexible coupling parallel mechanism described in this embodiment includes a combing cutterhead 1, a parallelogram connecting rod 2, a guide rod 3, a connecting rod 4, a crank 5, a power source 6, and an annular Enveloping cutter, upper base plate 9, lower base plate 10 and rigid-flexible coupling parallel mechanism; the combing cutter head 1 is processed with a plurality of radial and radially arranged guide grooves 101 along its circumferential direction; each guide groove 101 Correspondingly, there is a parallel four-bar linkage 2, wherein, the two sides of each parallel four-bar linkage 2 are respectively hinged with the adjacent parallel four-bar linkage 2, and a downward guide rod 3 is provided at its two ends, and the two A guide rod 3 is placed in the corresponding guide groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com