Bungee jumping rope crack detection and replacement equipment

A technology for crack detection and equipment replacement, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, grain processing, etc., and can solve problems such as misuse of bungee cords, breakage, and small cracks in bungee cords

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

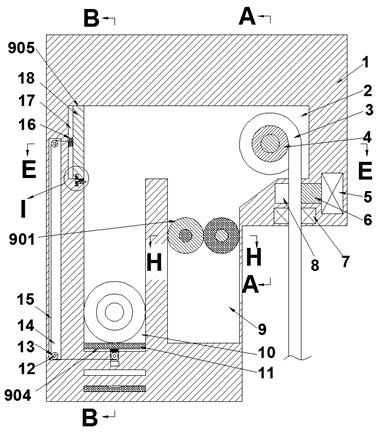

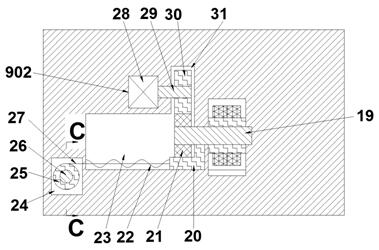

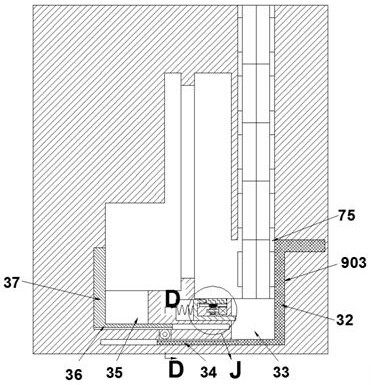

[0024] Combine below Figure 1-11 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0025]A bungee cord crack detection and replacement device described in conjunction with accompanying drawings 1-11 includes a fuselage 1, a fixed cavity 8 opening downward is arranged in the bottom wall of the fuselage 1, and the right wall of the fixed cavity 8 is fixed An output shaft left cylinder 5 is provided, and the end of the output shaft of the cylinder 5 is fixedly provided with a fixed block 6 extending left and right, and an ultrasonic crack detector 7 is fixedly provided in the bottom wall of the fixed chamber 8, and the top of the fixed chamber 8 The wall is provided with a main chamber 2, the bottom wall of the main chamber 2 is connected with a crushing chamber 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com