A kind of fried food production equipment and its application method for convenient salvage oil residue

A technology for fried food and production equipment, which is applied in the field of fried food production equipment, which can solve the problems of oil tank consumption, cumbersome gloves and oil splash, etc., and achieves reduced injection volume, smooth and stable movement, and reduced bottom area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

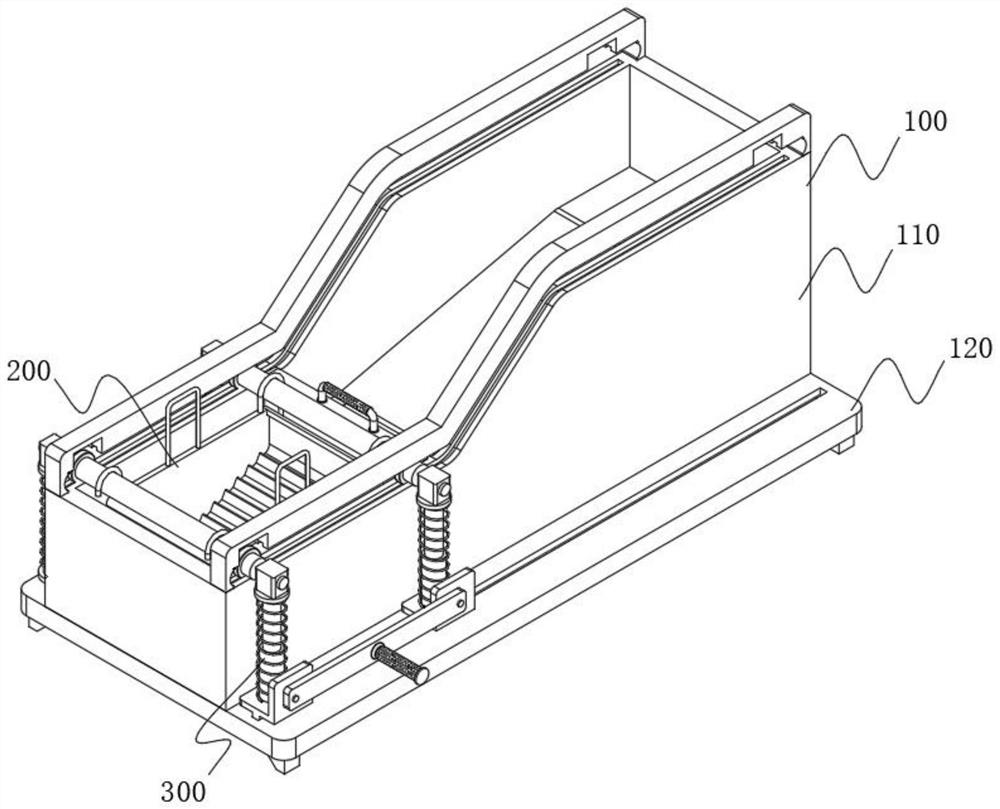

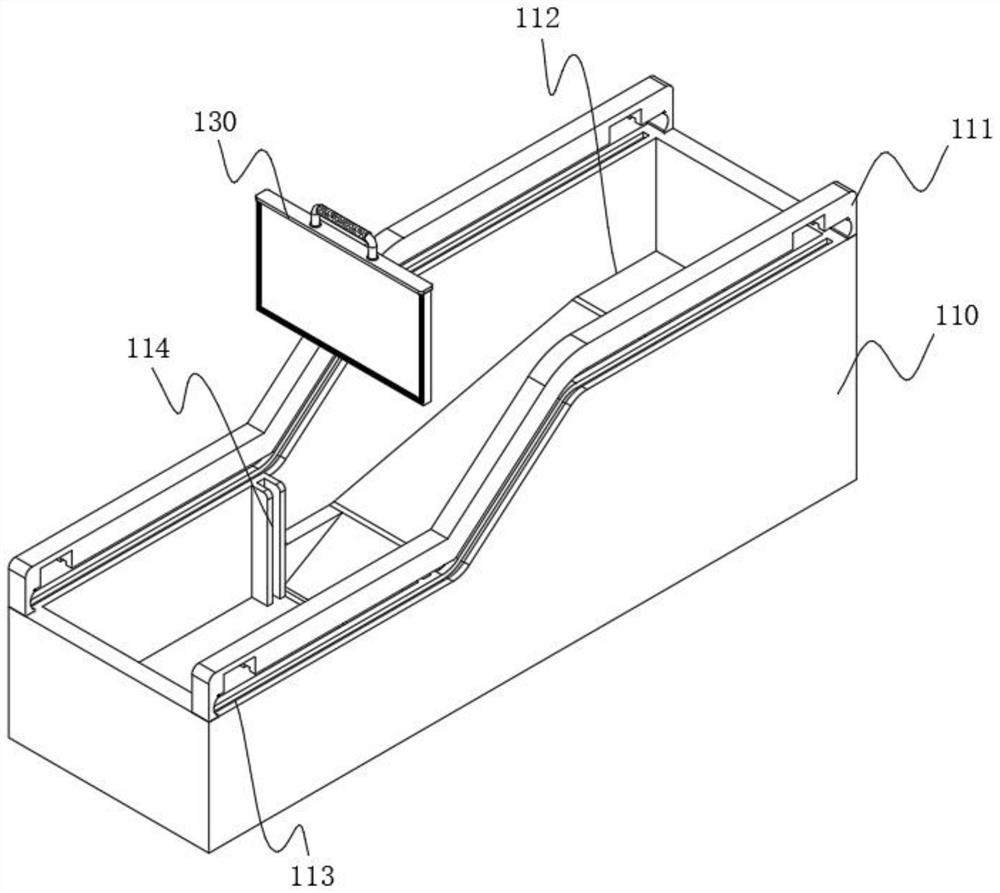

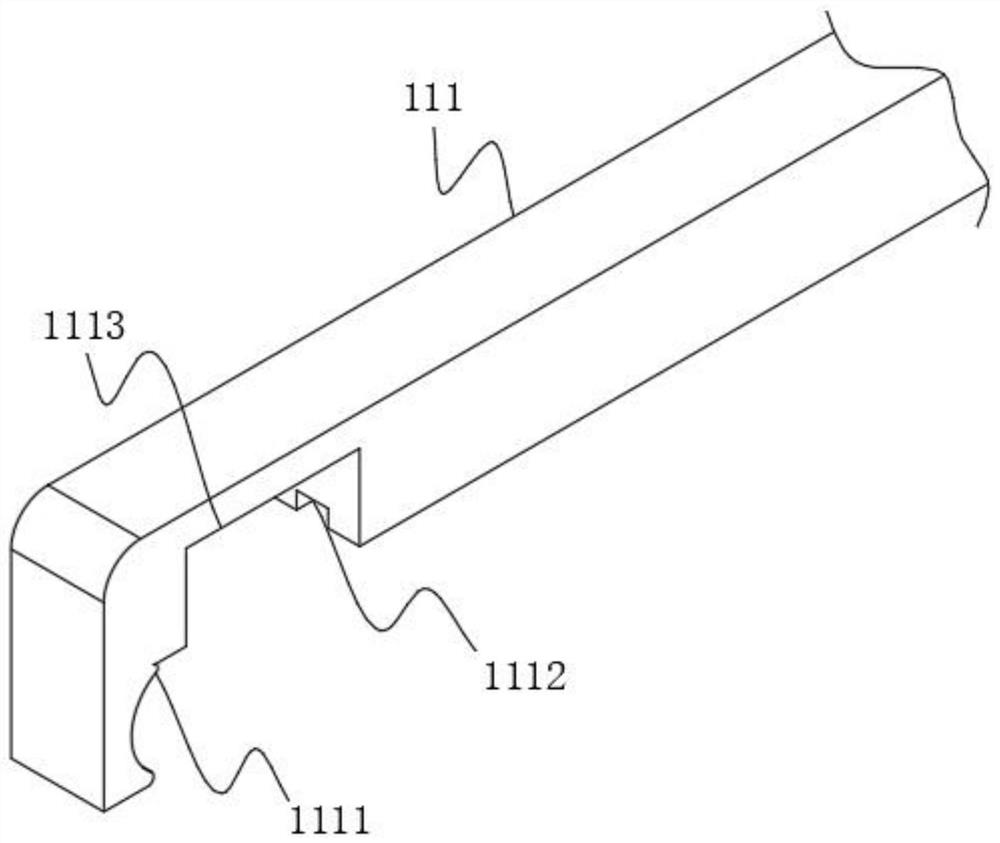

[0073] see Figure 1-Figure 15 As shown, one of the purposes of this embodiment is to provide a fried food production equipment that is convenient for salvaging oil residue, including a frying box 100 and a filter box 200 arranged inside the frying box 100, and the frying box 100 includes an outer box 110 , the outer box 110 is used to fill the oil, and the filling height of the oil is one-third of the bottom of the filter box 200. A guide groove 1111 is provided between the tops, a bottom plate 120 is fixedly connected to the bottom of the outer box 110, a left chute 122 and a right chute 121 are provided on the top of the bottom plate 120 close to the left and right sides of the outer box 110, and a filter box 200 is provided at the bottom. Net 240, the top of the filter box 200 is provided with a moving mechanism 300, the moving mechanism 300 at least includes a moving rod 310, the moving rod 310 passes through the guide groove 1111, the guide groove 1111 guides the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com