Special equipment for vertical roller induction heating aging

A technology of induction heating and special equipment, applied in the field of roll heating equipment, can solve problems such as bending and deformation of shaft parts, and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Other objects and advantages of the present invention will become clear by explaining the following preferred embodiments of the present invention.

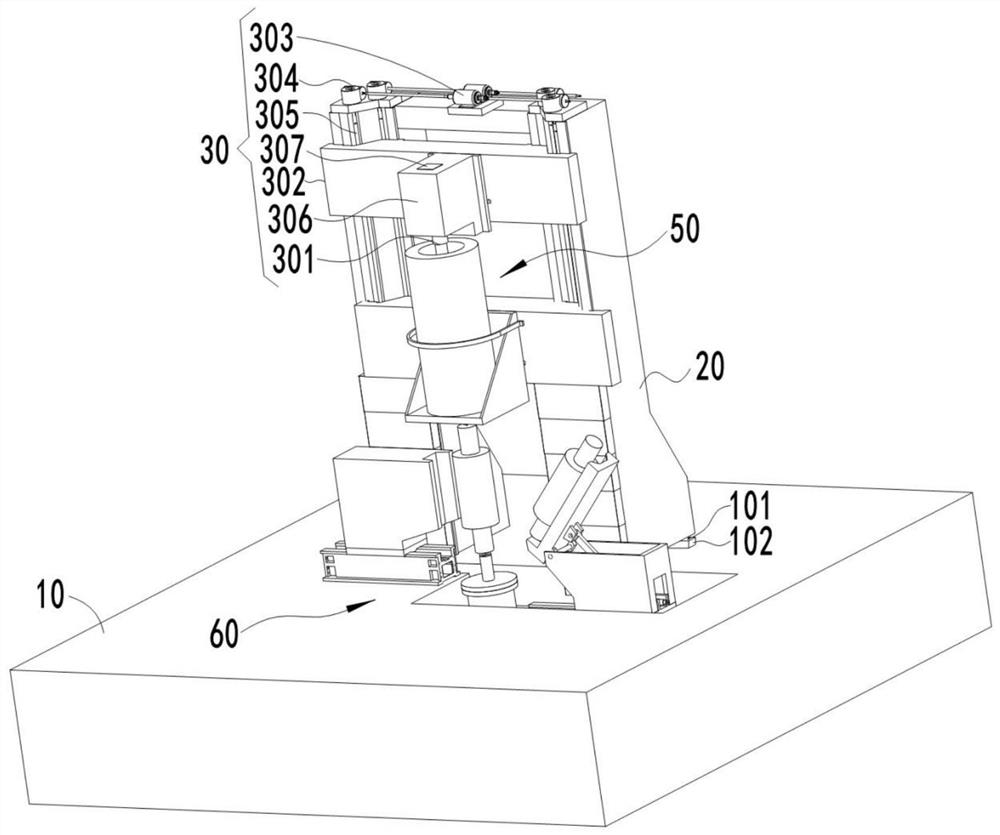

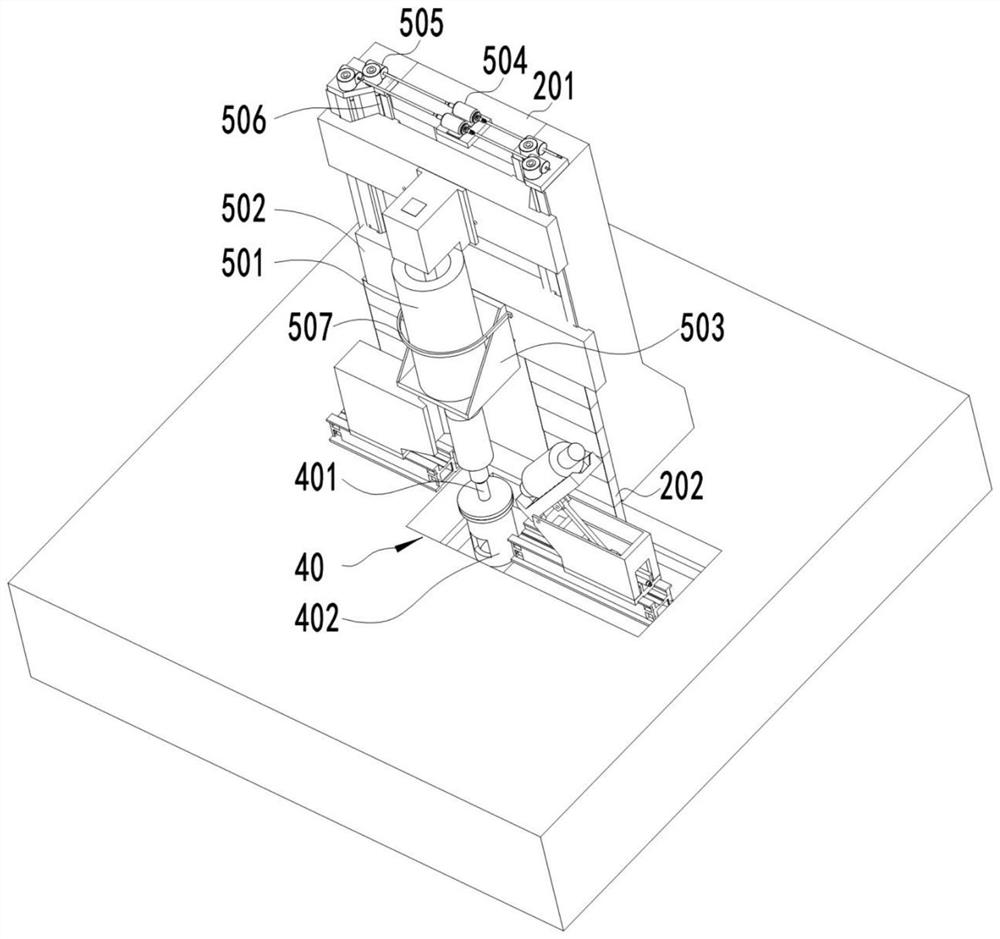

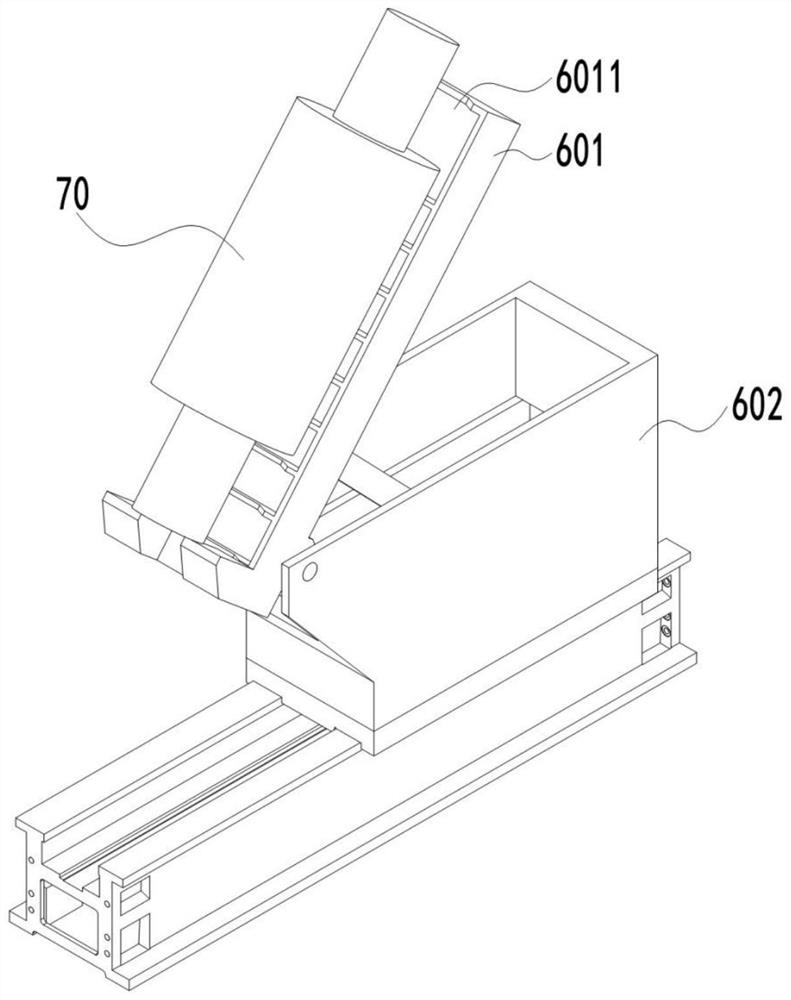

[0051] Figure 1-Figure 6 A schematic structural view of a special equipment for induction heating and aging of vertical rolls proposed by the present invention is shown. For the convenience of description, the "up", "down", "left" and "right" referred to below are consistent with the up, down, left and right directions of the drawings themselves, but do not limit the structure of the present invention.

[0052] A special equipment for induction heating and aging of vertical rolls, characterized in that it includes a base 10, a column 20 vertically arranged on the base 10, a clamping unit and a heating unit 50, wherein the clamping unit includes an upper clamping mechanism 30 and a lower clamping mechanism 40, the upper clamping mechanism 30 includes an upper jack 301 that can be lifted and lowered on the column 20, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com