Oil pan mounting bolt

A technology for installing bolts and oil pans, applied in the direction of bolts, screws, nuts, etc., which can solve problems such as easy loosening and uncompensated axial load of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

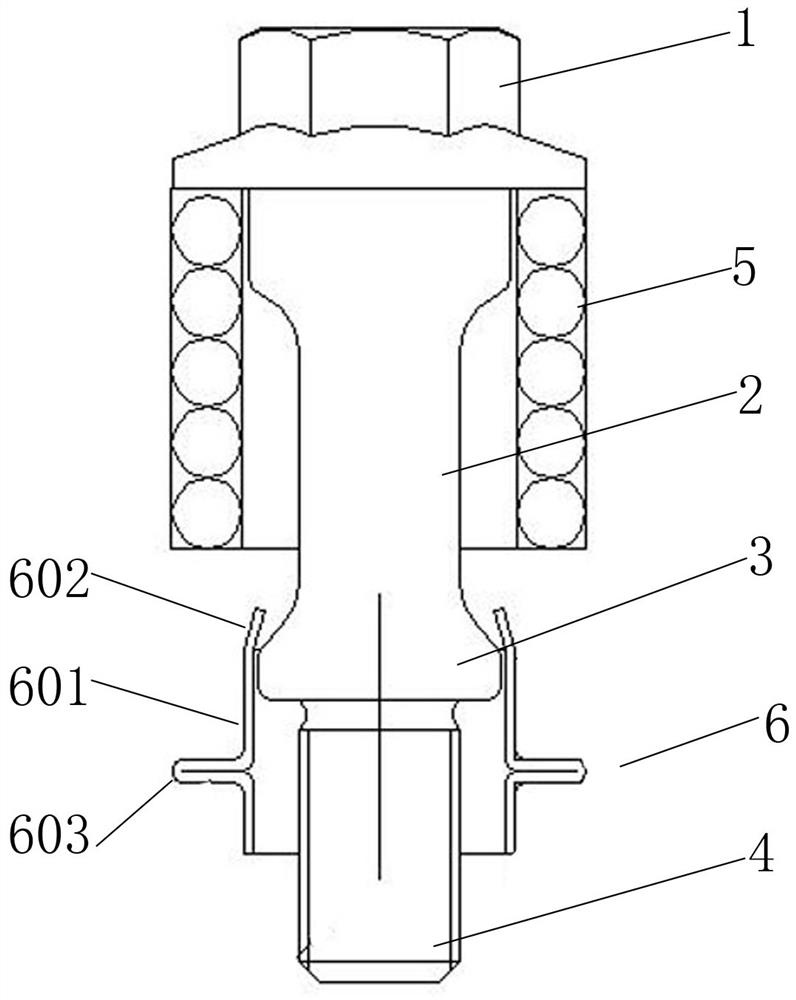

[0008] Such as figure 1 As shown, an oil pan installation bolt includes a bolt body. The bolt body is composed of a bolt head 1, a guide part 2, a limit part 3 and a threaded rod part 4 coaxially arranged from the beginning to the end to form a whole. There is a spring 5, the spring limit is limited on the guide part through the limit sleeve 6, the limit part can axially limit the limit sleeve, and the spring can make axial elastic deformation between the bolt head and the limit part ; That is, one end of the spring is against the bolt head, and the other end of the spring is against the limit sleeve; the threaded rod acts as a connection;

[0009] Such as figure 1 As shown, the structure of the limit sleeve 6 is as follows: a cylinder 601, three limit claws 602 are distributed around the upper port of the cylinder, and an annular body 603 is provided on the outer surface of the cylinder; the cylinder can guide Axial sliding on the part; the limit claw is to prevent the cyli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap