CNC tool holder for interchangeable mounting type CNC machine tool processing based on reliability considerations

A CNC machine tool and reliable technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unsatisfactory operation accuracy and efficiency, so as to improve the continuity of operations, improve efficiency, and continuously stabilize the adjustment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

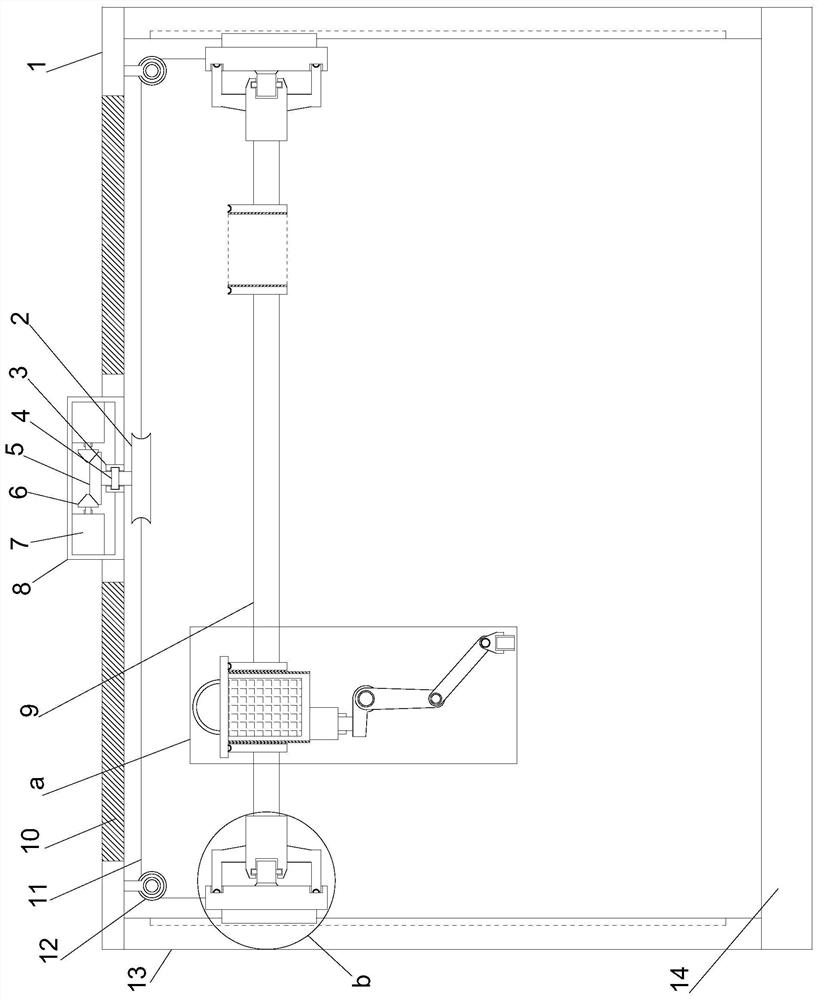

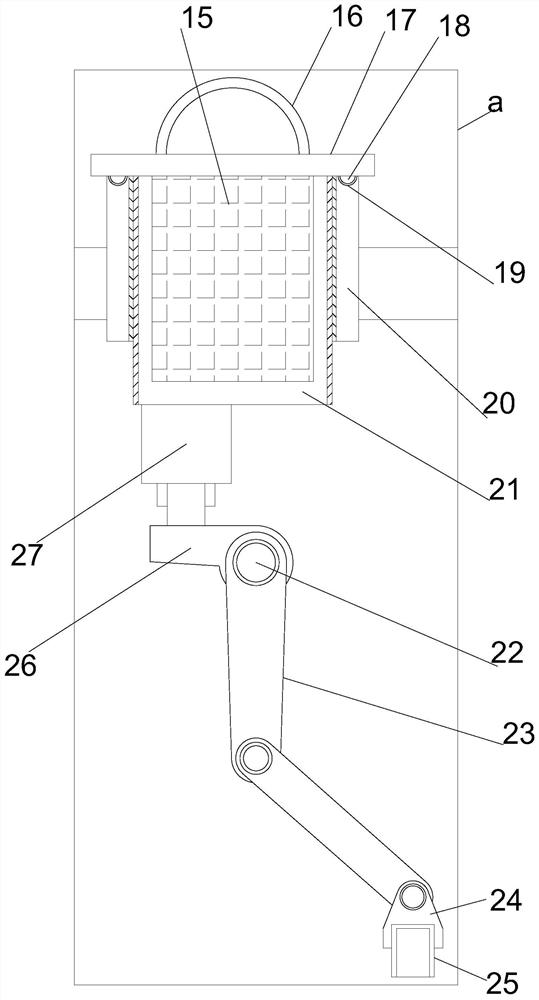

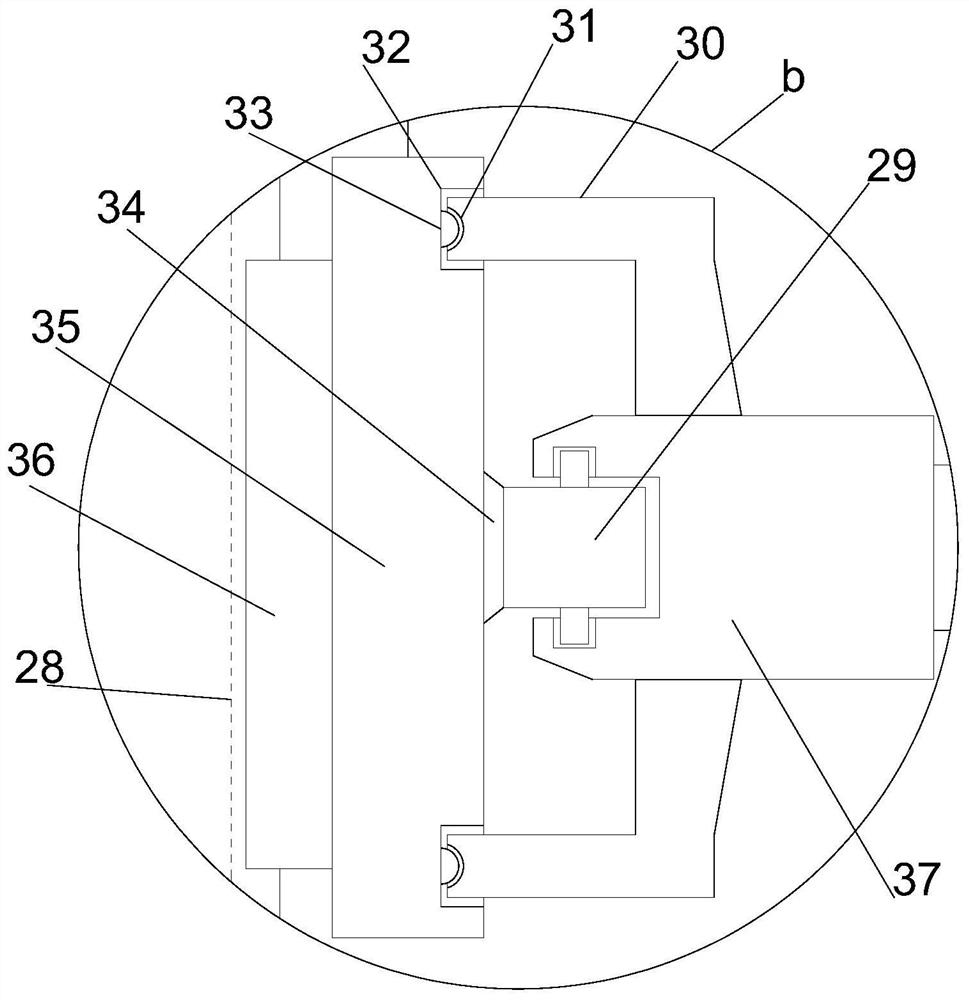

[0023] see Figure 1~4 , in the embodiment of the present invention, based on the consideration of reliability, the interchangeable mounting type numerical control tool holder for CNC machine tool processing includes a horizontally arranged support mounting plate 14, and the upper and lower ends of the support mounting plate 14 are symmetrically provided with mounting side plates 13, The installation side plates 13 are all vertically arranged, and the upper ends of the installation side plates 13 are horizontally connected with a top installation plate 1, and the upper middle position of the top installation plate 1 is vertically provided with a transmission installation cylinder 8, between the installation side plates 13 A lifting installation ring 35 is arranged horizontally, and the lifting installation ring 35 is vertically provided with a lifting guide column 36 on the side facing the installation side plate 13, and the installation side plate 13 is vertically provided wit...

Embodiment 2

[0026]On the basis of Embodiment 1, through the meshing of the driving gear 29 and the rotating gear ring 34, the synchronous rotation of the limit rotating ring 30 and the rotating installation disk 9 is realized. At this time, the tool installed in the internal thread installation cylinder 20 performs rotation and displacement operations , while rotating and displacing, the limit rotation ring 30 cooperates with the limit rotation groove 32, so that the device has good rotation stability. With the cooperation of the lifting guide column 36 and the lifting guide groove 28, stable lifting adjustment is realized. Through the cooperation of the annular conductive groove 19 and the extruded conductive ring 18, and the cooperation of the rotating conductive ring 33 with the rotating conductive groove 31, the power supply stability of the device is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com