Turnout steel rail damage identification method

An identification method and technology of turnout, applied in the field of rail transit, can solve the problem that the detection scheme cannot be applied to the rail of the turnout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

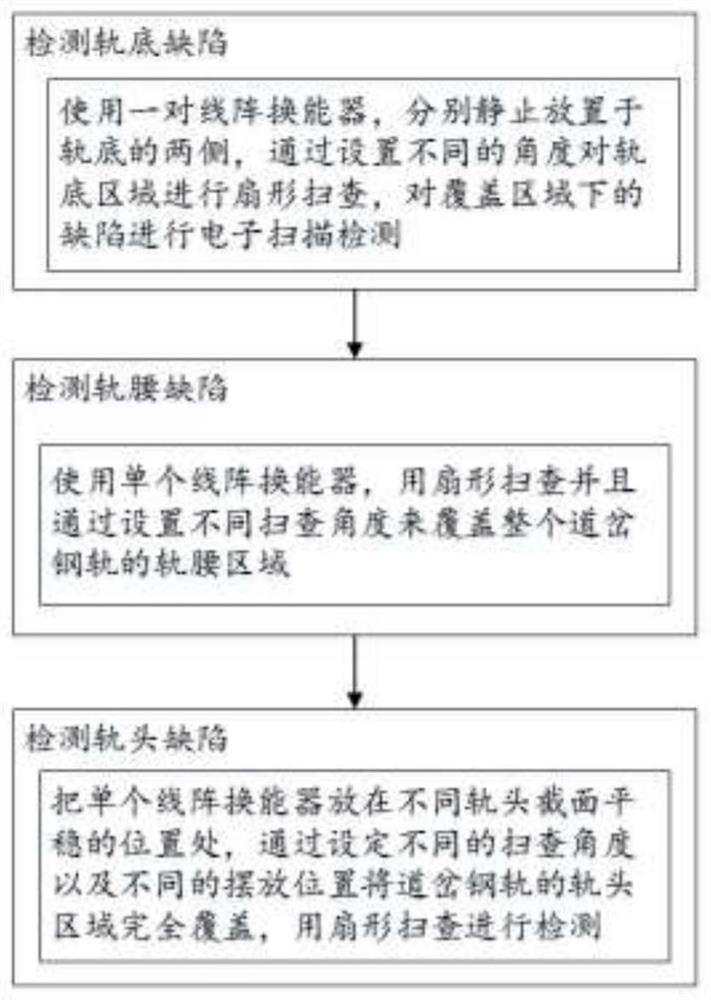

[0022] Such as figure 1 As shown, this embodiment provides a method for identifying damage to a turnout rail, which includes the following steps:

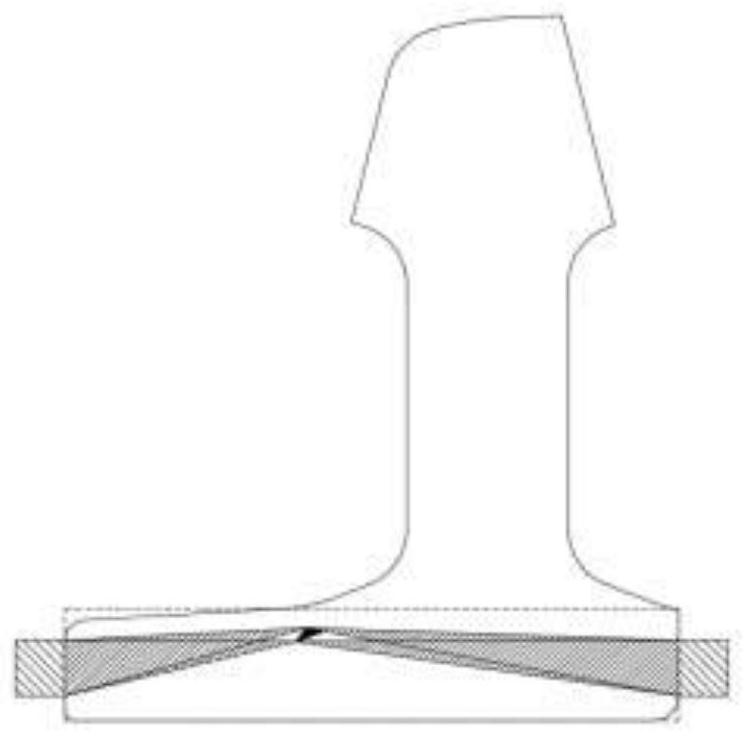

[0023] 1. Detection of rail bottom defects: use a pair of linear array transducers, which are placed statically on both sides of the rail bottom, and perform sectoral scanning on the rail bottom area by setting different angles, and electronically scan and detect defects under the coverage area ;

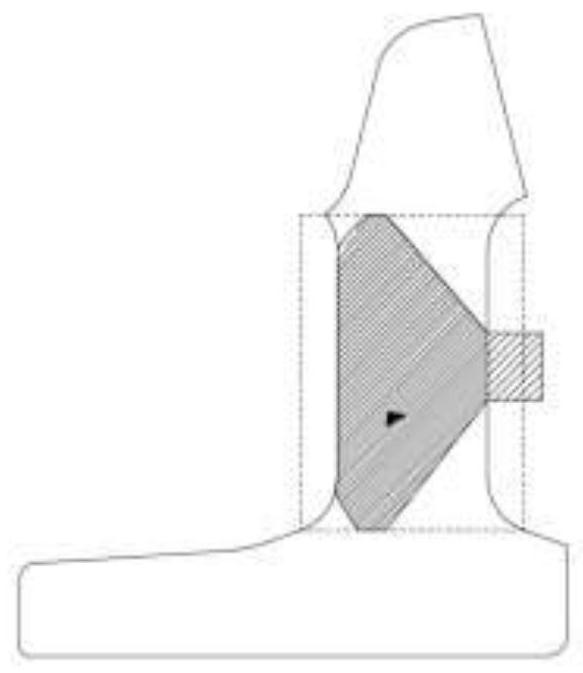

[0024] 2. Detection of rail waist defects: Considering the characteristics of the continuously variable section of the turnout rail, the phased array device cannot be placed smoothly on the rail head of some sections, and considering the length and width of the rail waist area, a single linear array transducer is used The device uses fan-shaped scanning and sets different scanning angles to cover the rail waist area of the entire turnout rail; the detection scheme for the bottom of the rail is as follows: image 3 shown;

[0025] 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com