Working method of transportation device

A technology of a transport device and a working method, applied in the field of transport devices, can solve the problems of inability to adapt to shock absorption requirements, fixed shelf structure, prone to vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

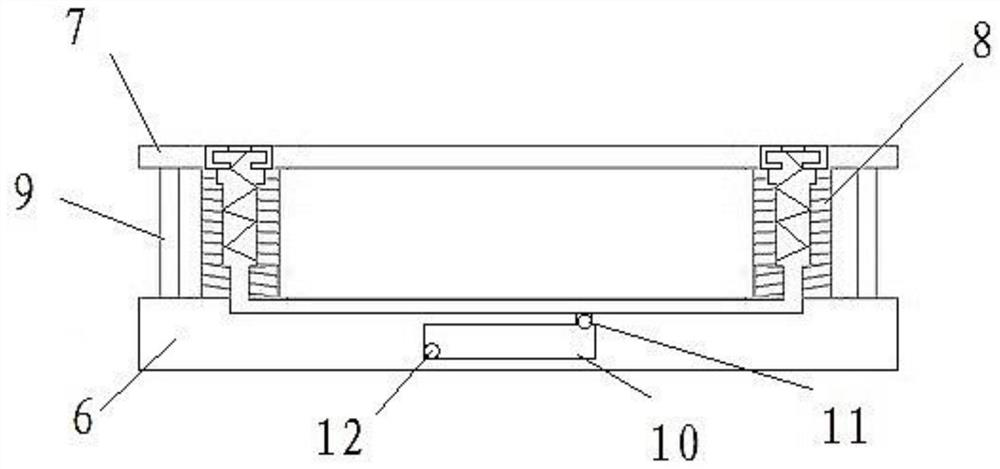

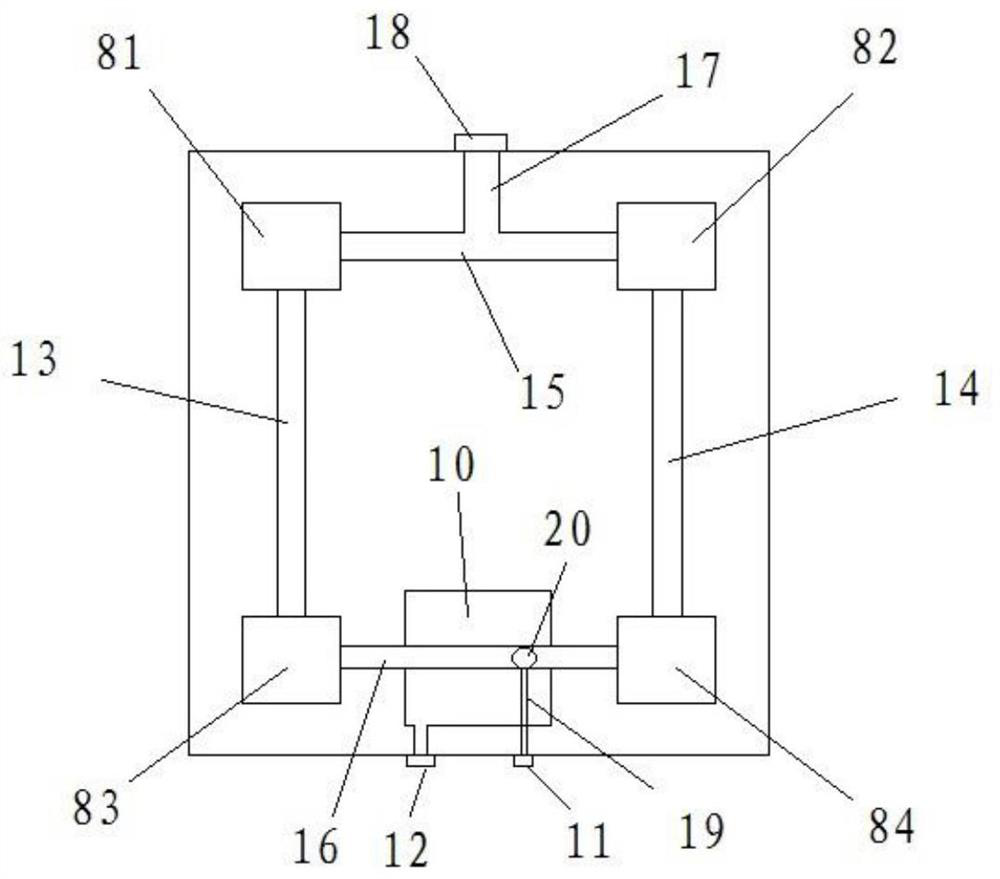

[0048] As shown in the figure: a working method of a transportation device, the transportation device includes a traveling mechanism and a carrying mechanism, and a quick connection can be realized between the traveling mechanism and the carrying mechanism; the traveling mechanism includes a main frame, a handle, and a driving structure , support bracket, insert plate, main wheel, supporting legs, auxiliary wheels; the handle is provided on one side of the main frame, the support bracket is provided on the other side of the main frame, and the lower part of the support bracket A flashboard is provided, the number of the flashboards is two, the driving structure is fixed on the main frame and drives the support bracket to move up and down, the main wheel and the legs are arranged under the main frame, and the support The end of the leg is provided with the auxiliary wheel; the working method includes: working state switching method, stable transfer method;

[0049] The carrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com