Door lock structure and cleaning machine applying door lock structure

A door lock structure and keyhole technology, which is applied in the washing machine/washing machine for tableware, application, and parts of the washing machine/rinsing and washing machine for tableware, etc. , prone to failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

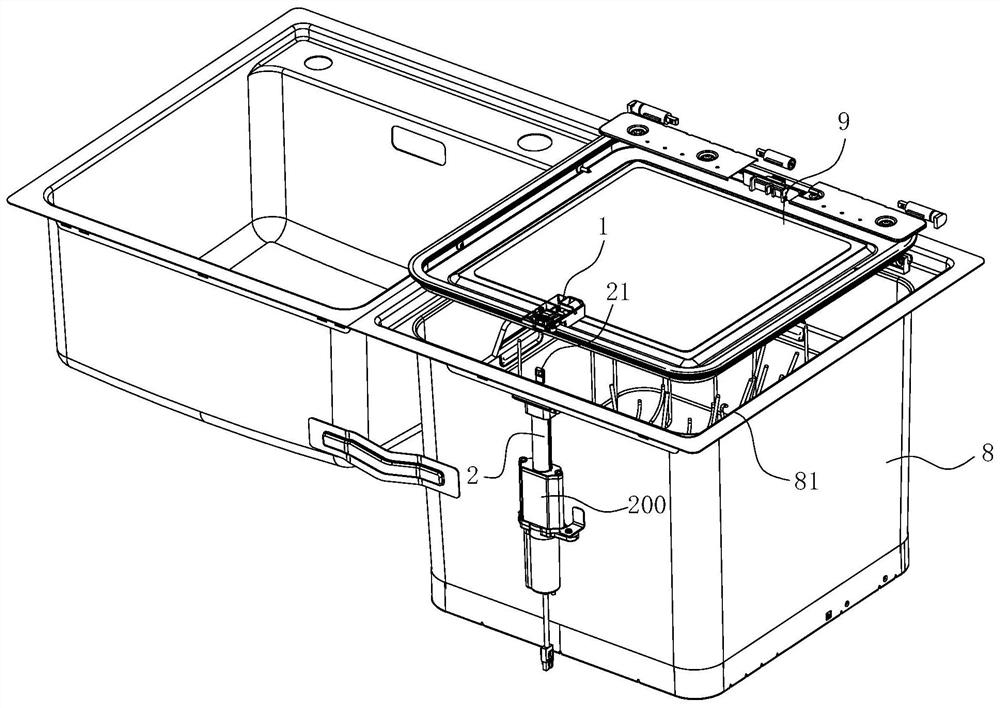

[0044] Such as Figure 1-8 As shown, the door lock structure of this embodiment is used to lock any door body and box body, and this embodiment uses a cleaning machine as an example for illustration. The washing machine of this embodiment comprises a box body 8 and a door body 9, the box body 8 has a washing chamber and an upper port 81 connected to the top of the washing chamber, and an edge of the door body 9 is connected to the edge of the upper port 81 of the box body 8 by rotation place.

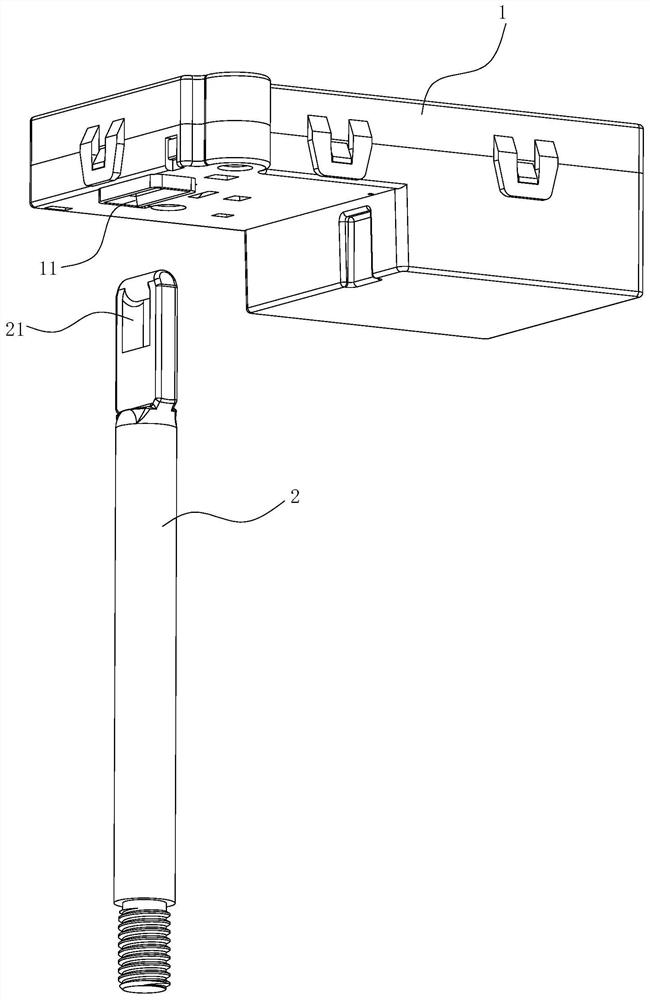

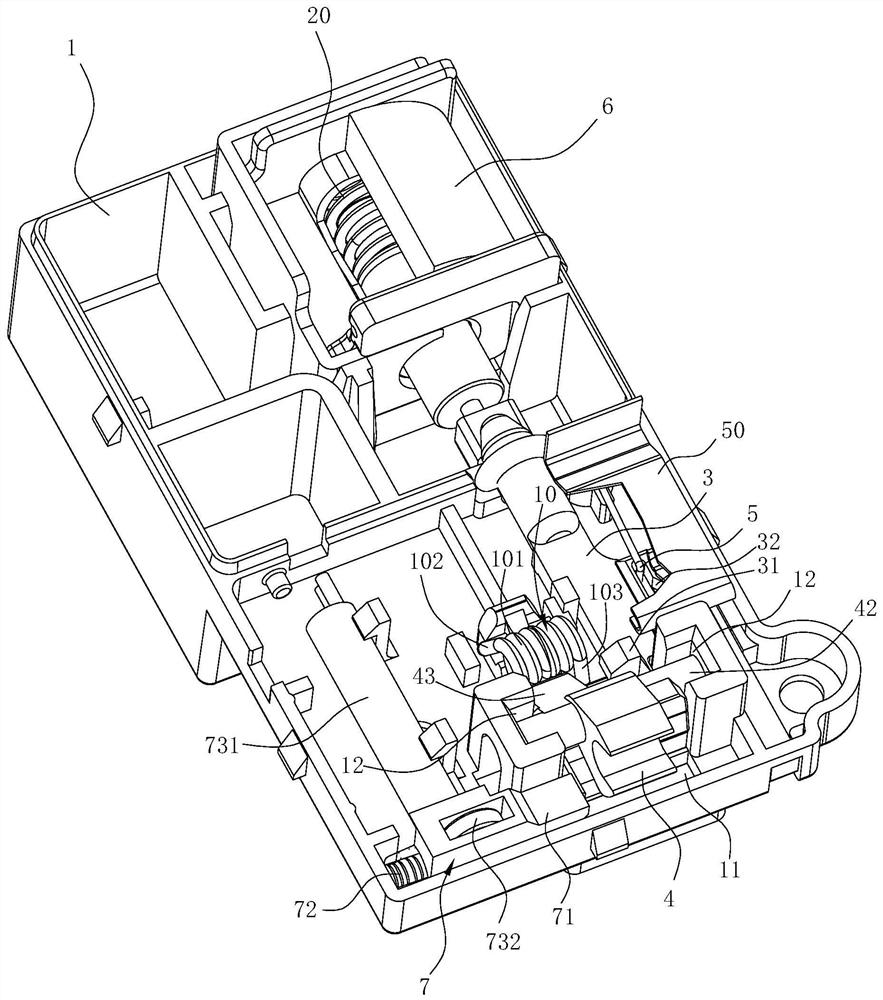

[0045] The door lock structure of this embodiment includes a housing 1 , a push rod 2 , a latch 4 , a first elastic member 10 , a locking plate 3 , a positioning pin 5 , a second elastic member 20 and a driving mechanism 6 . Wherein, the housing 1 is arranged on the door body 9 , and the bottom wall of the housing 1 is provided with a lock hole 11 penetrating up and down. The ejector rod 2 can be moved up and down on the side wall of the box body 1, the upper end of the ejector rod 2 ...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 lies in that the structure of the trigger assembly 7 of this embodiment is different from that of Embodiment 1.

[0057] Such as Figure 9As shown, the trigger switch 73' of this embodiment includes a photoelectric module 731' and a shading plate 732', the first end of the shading plate 732' can cooperate with the photoelectric module 731' to form a photoelectric switch, and the second end side of the slider 71' The wall forms a first guide surface 711' that gradually inclines toward the buckle 4 from front to back, and the visor 732' is provided in the housing 1 so that it can move forward and backward, and the side wall at the second end forms a guide surface that can guide with the first guide surface 711'. The matching second guide surface 733', the photoelectric module 731' is disposed at the rear end of the light shielding plate 732'.

[0058] In the state of opening the door, the first end (ie, the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com