Operating handle type socket

A technology of operating handles and sockets, applied in the direction of coupling devices, electrical components, connections, etc., can solve problems such as poor contact, insufficient tightening force, and wire L falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

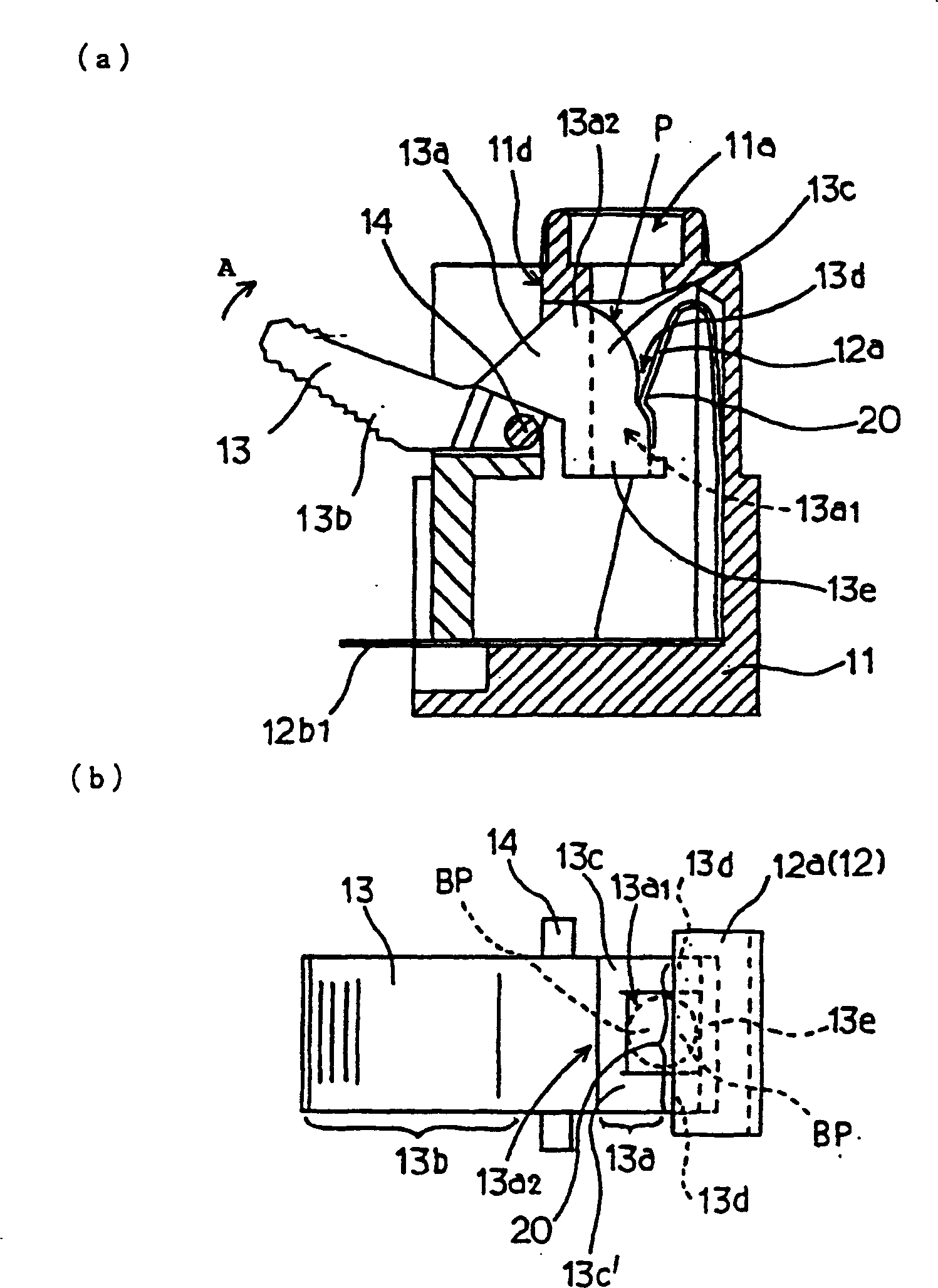

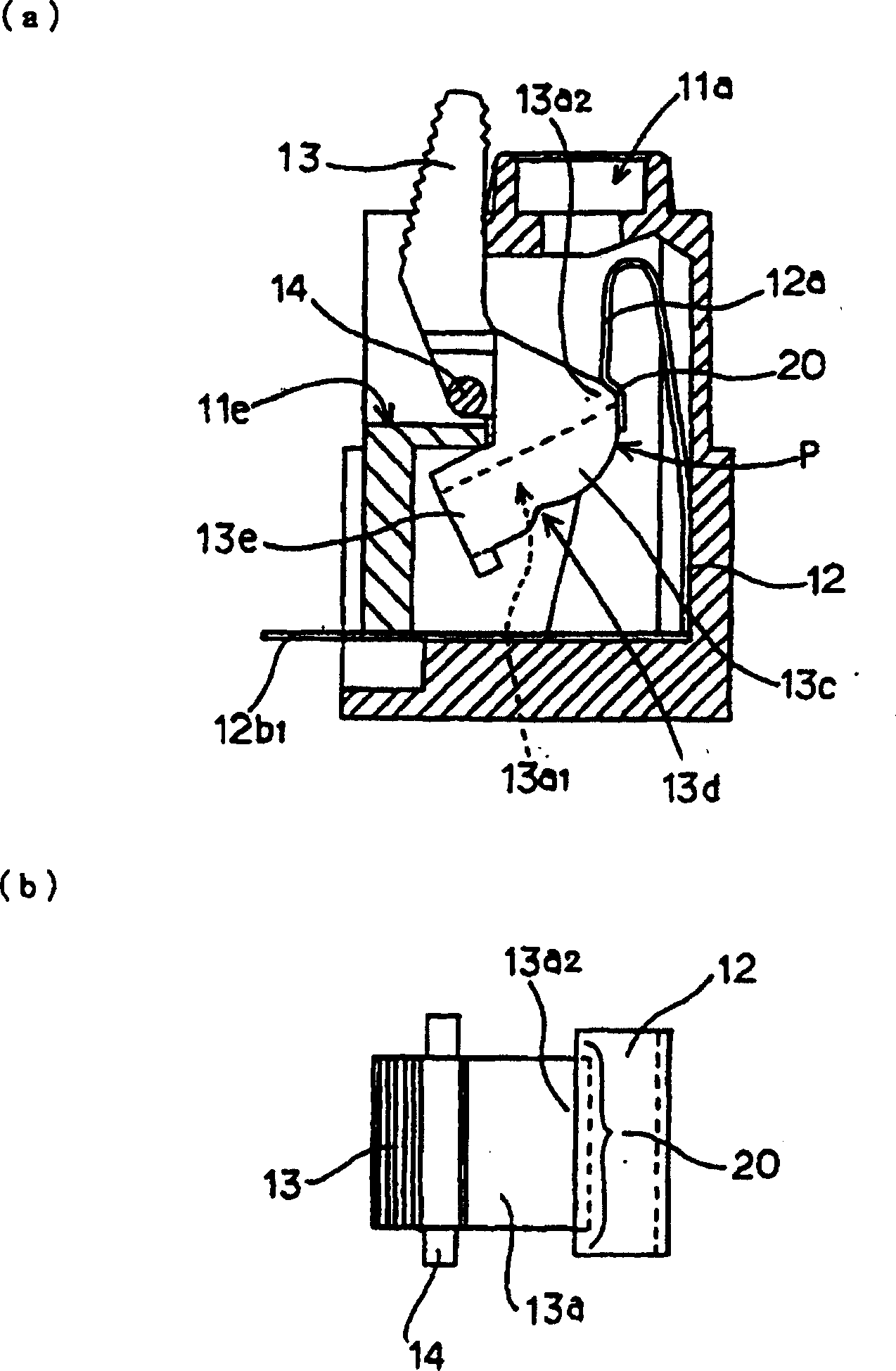

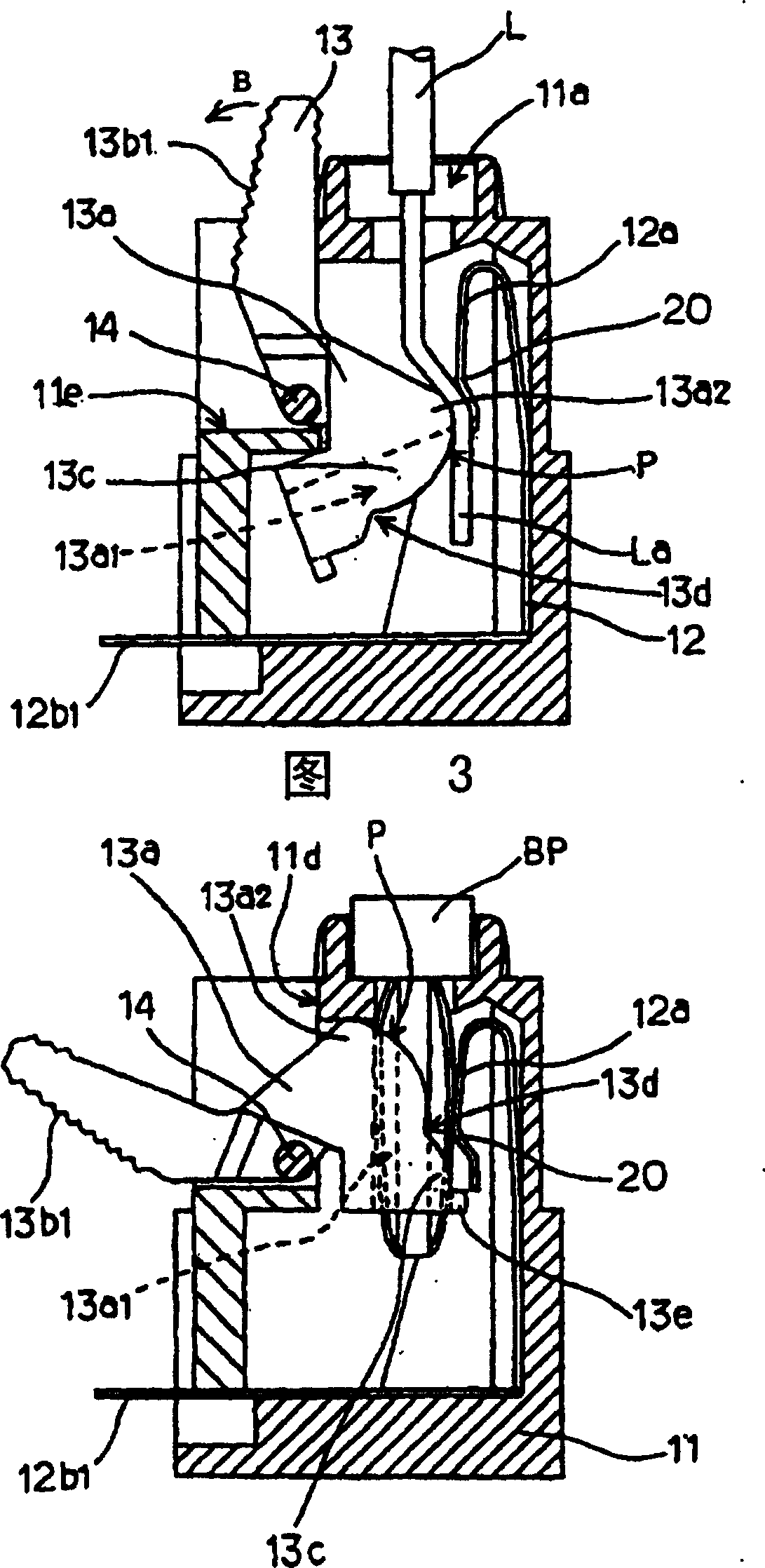

[0031] Figure 1 to Figure 4 is the main part respectively showing an embodiment of the handle type socket of the present invention, wherein, figure 1 is to show the open state of the handle; figure 2 It shows the state that the handle is closed; Figure 3 shows the connection state of the wire; Figure 4 is to show the connection status of the banana plug.

[0032] Figure 1 to Figure 4 Among them, 11 is a shell made of insulating material, which has a conductor insertion hole 11a for the connected conductor, that is, the wire L and the banana plug BP to be freely plugged in and out. Here, the structure of wire L and banana plug BP is the same as Figure 8 to Figure 10 The structure of the conventional connected conductors shown in .

[0033] Generally speaking, the diameter of the lead wire L and the banana plug BP is larger, so the diameter of the conductor insertion hole 11a is set to be the smallest diameter that can be inserted and removed by the banana plug BP. Fu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap