Folding mechanism for a conveyor device

A technology for conveying devices and conveyors, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., to achieve the effects of smooth operation, simple installation, and reliable absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

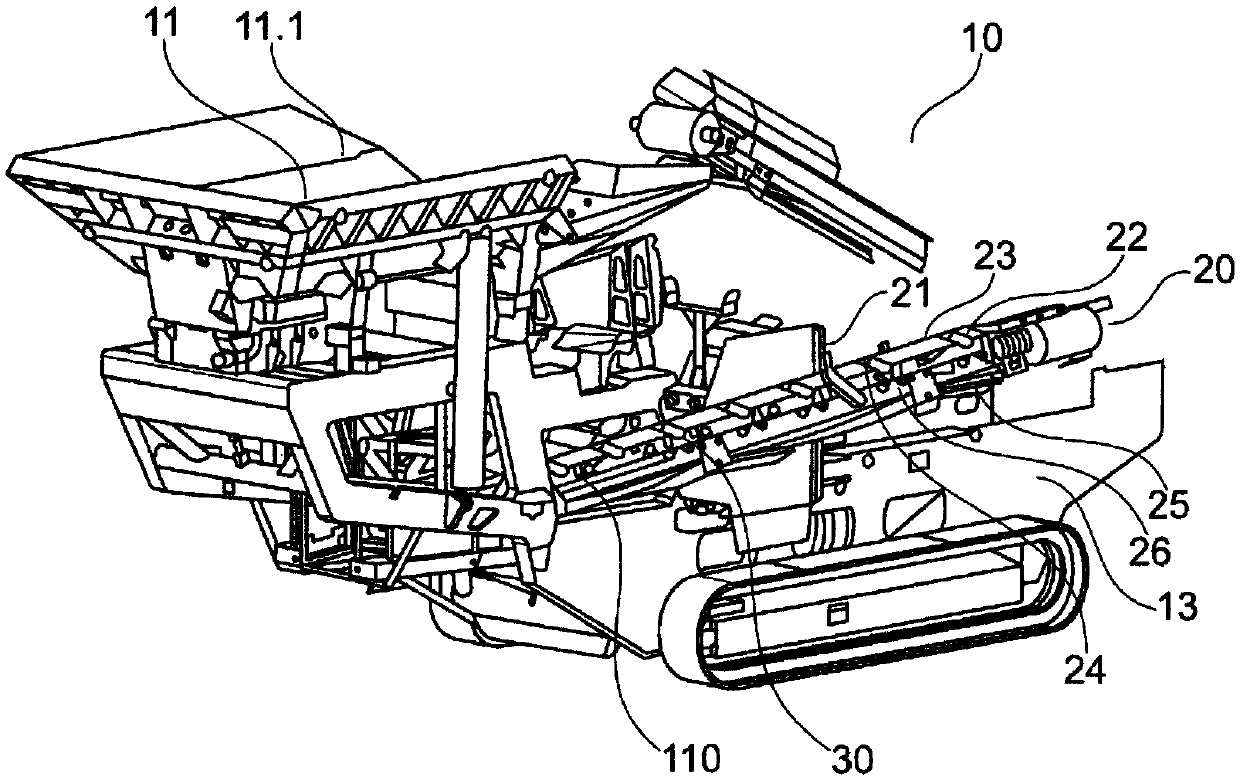

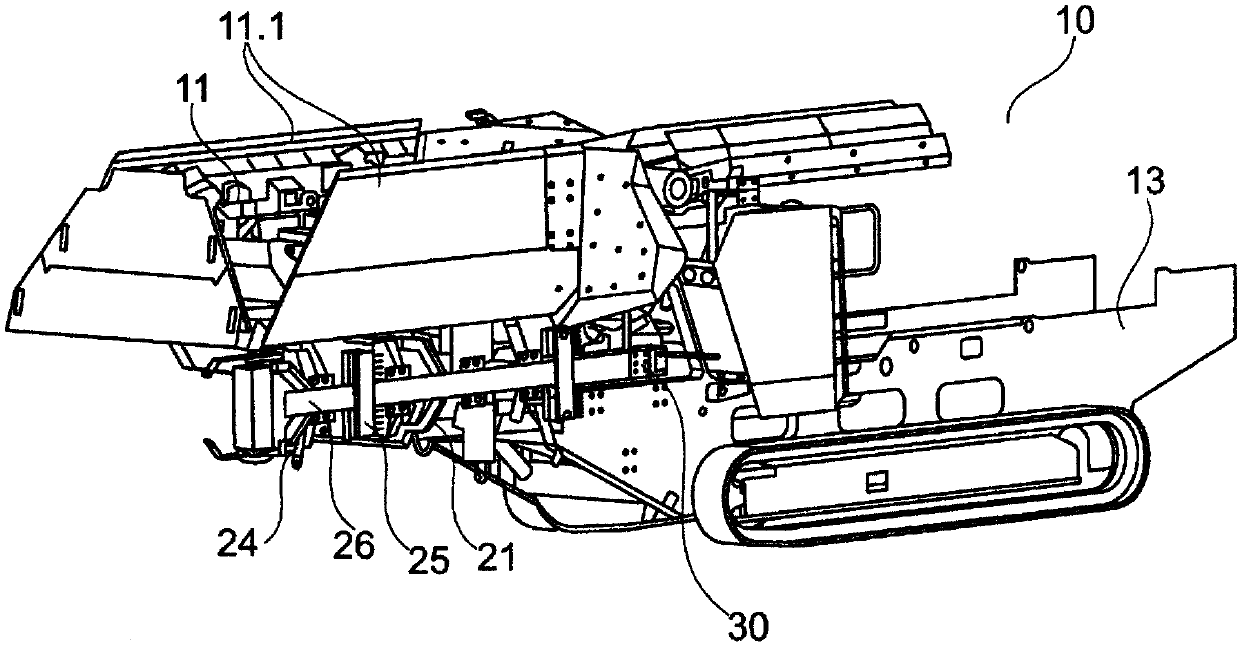

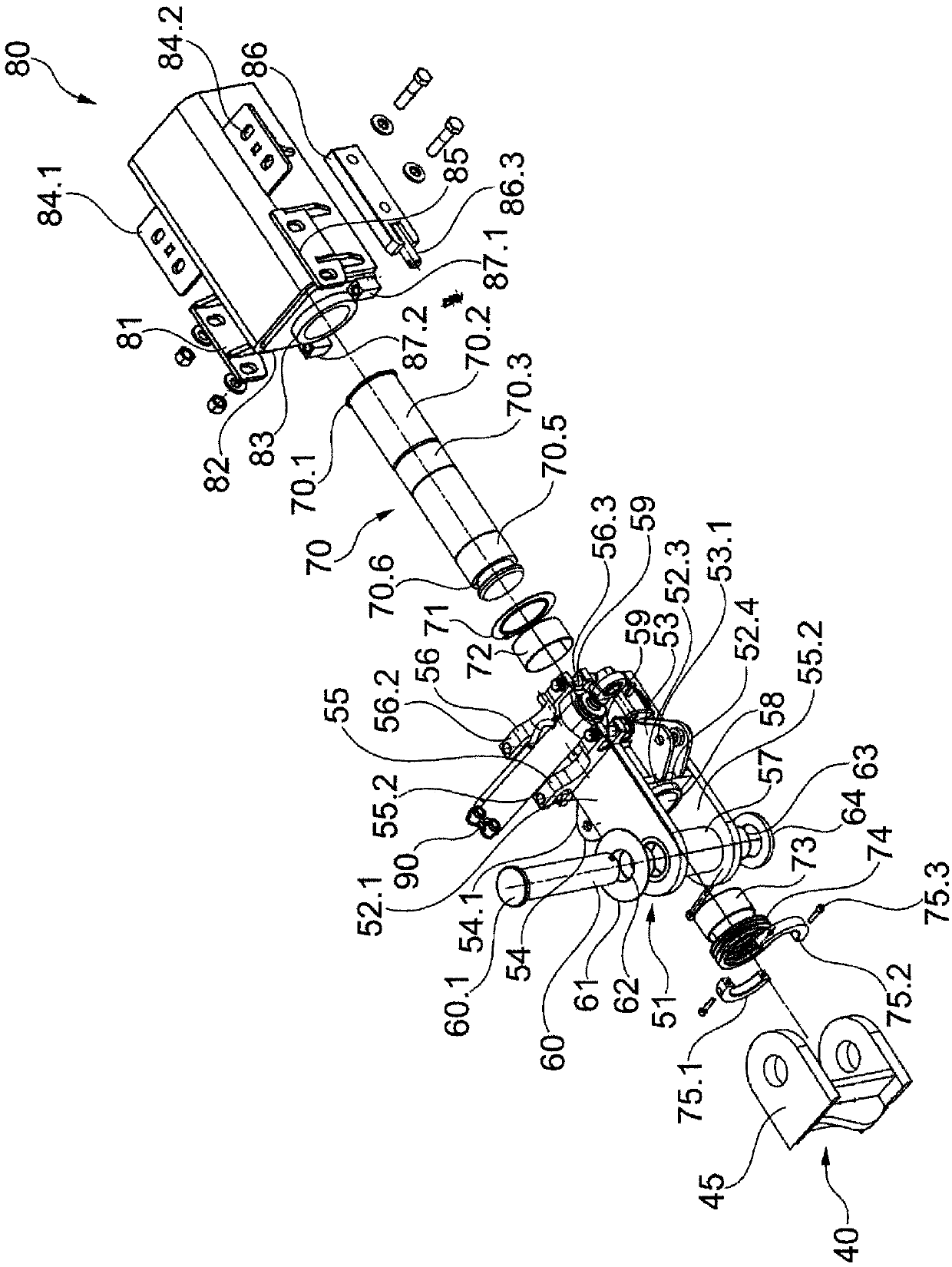

[0030] figure 1 The movable material processing apparatus is shown in an operating position. The material processing device 10 is used for crushing excavated material, which is fed to the material processing device 10 through a feed hopper 11 having a funnel wall 11.1. Material is removed by means of a conveyor arrangement 20 . The conveyor arrangement 20 is connected to the chassis 13 of the mobile material processing arrangement 10 by a base portion 110 . The transport section 24 of the conveyor arrangement 20 is connected to the base section 110 by a joint section 30 . The belt 23 of the conveyor device 20 is guided along the supporting profile 26 of the transport section 24 . For this purpose, a belt 23 is mounted on rollers 22 and is held transversely by transverse belt guides 21 and is situated on the bottom side of the conveyor arrangement 20 by bottom belt guides 25 .

[0031] The base part 110 is connected to the chassis 13 so as to move in such a way that the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com