Fire cover, burner comprising fire cover and gas stove

A gas cooker and burner technology, which is applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problems that the maximum firepower of the burner cannot be effectively improved, and the amount of combustible oxygen is insufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

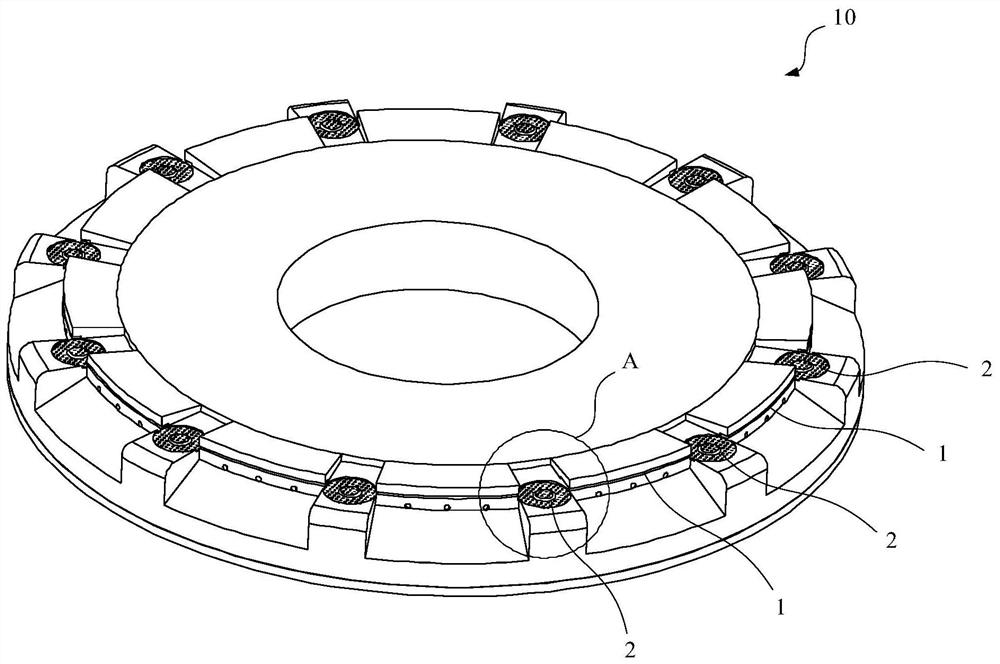

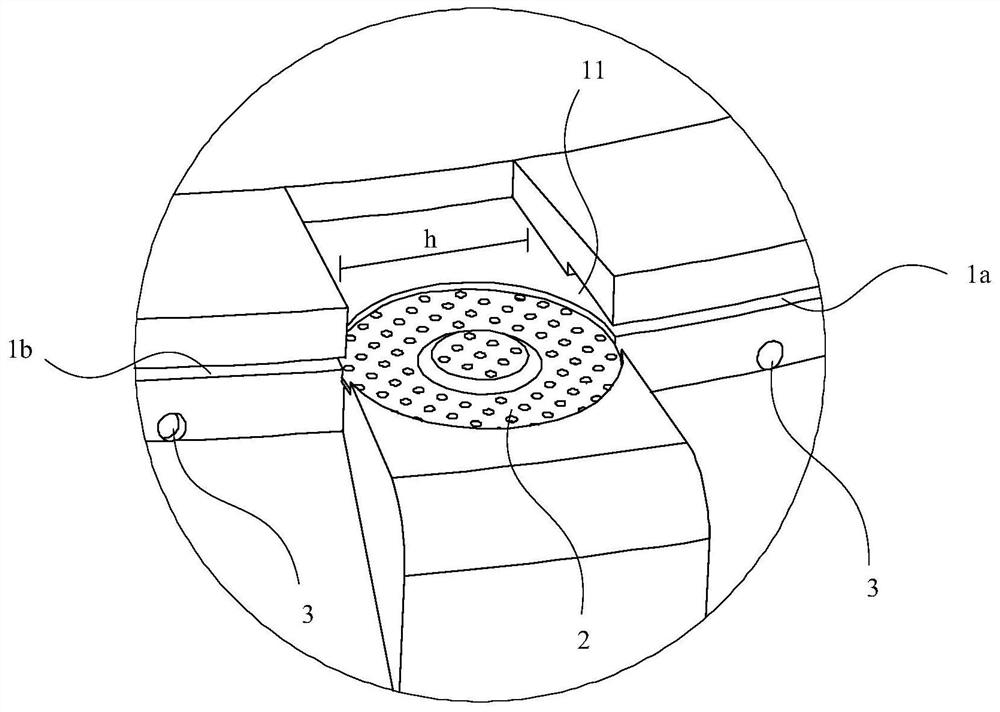

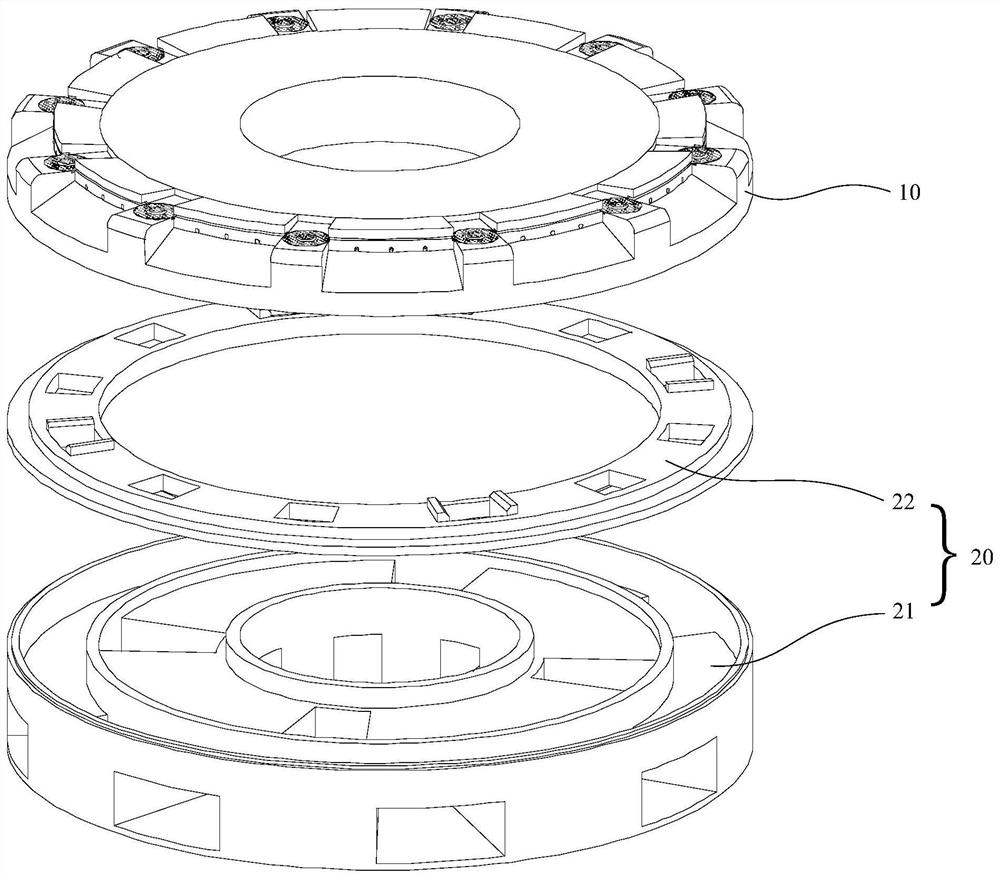

[0072] like figure 1 As shown, the present invention provides a kind of fire cover 10, is provided with some first fire hole units 1 and the second fire hole unit 2 on the surface of fire cover 10, wherein, the first fire hole unit 1 and the second fire hole unit 2 are alternately arranged in sequence along the circumferential direction of the fire cover 10.

[0073] Both the first fire hole unit 1 and the second fire hole unit 2 are unspecified fire hole structures, which are respectively connected to an external gas source for ignition and combustion. Wherein, when the second fire hole unit 2 is not ignited, fire can be transmitted between adjacent first fire hole units 1, so that all the first fire hole units 1 can be ignited at the same time, corresponding to the traditional burner The heating state when the inner ring f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com