Al-zn-cu-mg alloys and their manufacturing process

An aluminum-based alloy, mg1.55 technology, applied in the field of aluminum-based alloys, can solve the problems of long aging time and difficulty in mastering the three-step process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

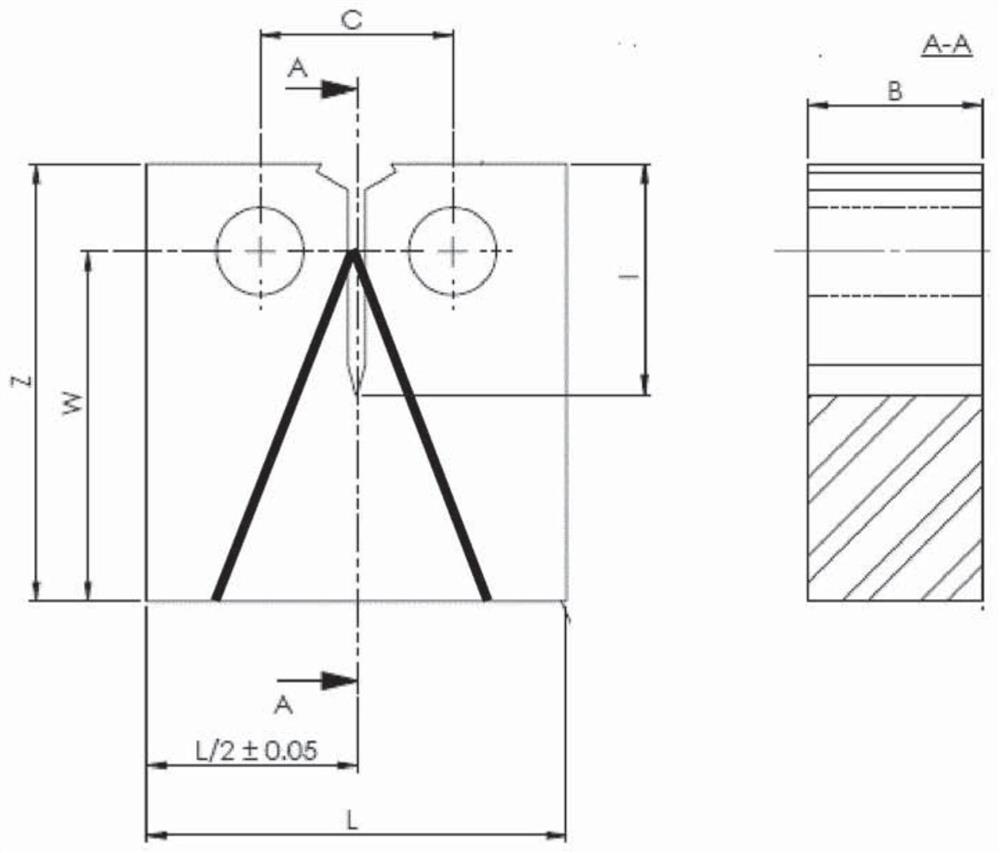

Image

Examples

Embodiment 1

[0092] Two ingots were cast, one a product of the invention (A) and one a comparative example (B), having the following composition (Table 1):

[0093] Table 1: Composition (% by weight) of inventive and control castings.

[0094] alloy Si Fe Cu Mg Zn Ti Zr A 0.03 0.04 2.13 1.75 7.05 0.04 0.06 B 0.05 0.09 1.64 2.25 6.10 0.02 0.11

[0095] The ingots were then peeled and homogenized at about 475°C. The ingots were hot rolled into plates with a thickness of 102 mm (alloy A) or 110 mm (alloy B). The hot-rolling inlet temperature of alloy A is 350°C, and the hot-rolling inlet temperature of alloy B is 440°C. The panels were solution heat treated at a soak temperature of about 475°C. The plates were quenched and stretched with a permanent elongation of 2.0 to 2.5%.

[0096] The control plate was aged in two steps: 4 hours at 120°C followed by 15 hours at 155°C for a total equivalent time of 17 hours at 155°C to obtain the T7651 t...

Embodiment 2

[0116] Another ingot was cast, which had a composition according to the invention (C), (Table 6):

[0117] Table 6: Composition of Casting C (% by weight).

[0118] alloy Si Fe Cu Mg Zn Ti Zr C 0.03 0.04 2.15 1.65 7.11 0.03 0.10

[0119] The ingots were then peeled and homogenized at 475°C. The ingots were hot rolled into plates with a thickness of 152 mm. The hot rolling entrance temperature was 420°C. The panels were solution heat treated at a heat soak temperature of about 475°C. The plates were quenched and stretched with a permanent elongation of 2.0 to 2.5%.

[0120] Due to the high hot rolling temperature, the microstructure of the plate is different from the present invention, the plate produced has less than 20% recrystallized grains in the middle of the thickness.

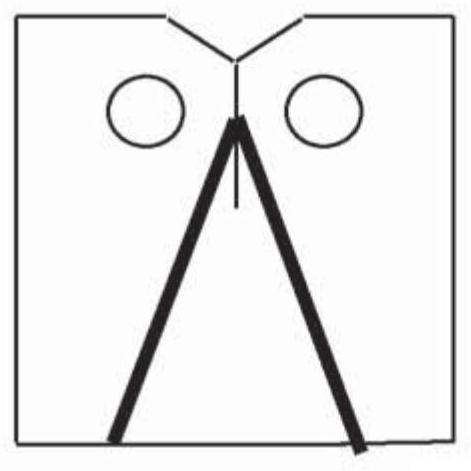

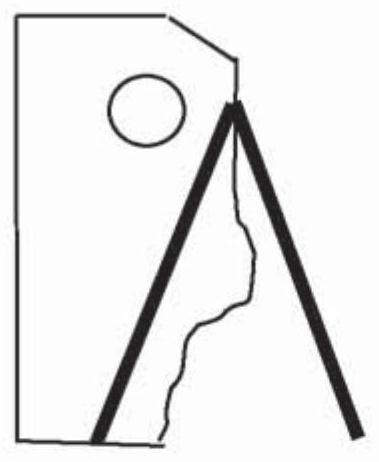

[0121] Under the maximum load of 4KN and R=0.1, on the CT sample (CT10W40, thickness 10mm, width 40mm) along the L-S direction at the middle of the thickness and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com