Al-zn-cu-mg alloys and their manufacturing process

a technology of aluminum base alloys and manufacturing processes, applied in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of difficult to take into account design parts, consider detrimental, and consider crack deviation, so as to improve the growth rate of fatigue cracks and increase the tendency of crack deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Example 1

[0083]Two ingots were cast, one of a product according to the invention (A), and one reference example (B) with the following composition (Table 1):

TABLE 1composition (wt. %) of a cast accordingto the invention and a reference cast.AlloySiFeCuMgZnTiZrA0.030.042.131.757.050.040.06B0.050.091.642.256.100.020.11

[0084]The ingots were then scalped and homogenized at about 475° C. The ingots were hot rolled to a plate of thickness of 102 mm (alloy A) or 110 mm (alloys B). Hot rolling entry temperature was 350° C. for alloy A and 440° C. for alloy B. The plates were solution heat treated with a soak temperature of about 475° C. The plates were quenched and stretched with a permanent elongation comprised between 2.0 and 2.5%.

[0085]The reference plates were submitted to a two-step aging of 4 hours at 120° C. followed by approximately 15 hours at 155° C. for a total equivalent time at 155° C. of 17 hours, to obtain a T7651 temper.

[0086]The plates made of alloy A had at mid-thickness m...

example 2

[0095]One additional ingot was cast, with a composition according to the invention (C), (Table 6):

TABLE 6composition (wt. %) of cast C.AlloySiFeCuMgZnTiZrC0.030.042.151.657.110.030.10

[0096]The ingot was then scalped and homogenized at 475° C. The ingot was hot rolled to a plate of thickness of 152 mm Hot rolling entry temperature was 420° C. The plate was solution heat treated with a soak temperature of 475° C. The plate was quenched and stretched with a permanent elongation comprised between 2.0 and 2.5%.

[0097]Due to the high hot rolling temperature, the plate microstructure was not according to the invention, the plate made had at mid-thickness less than 20% of recrystallized grains.

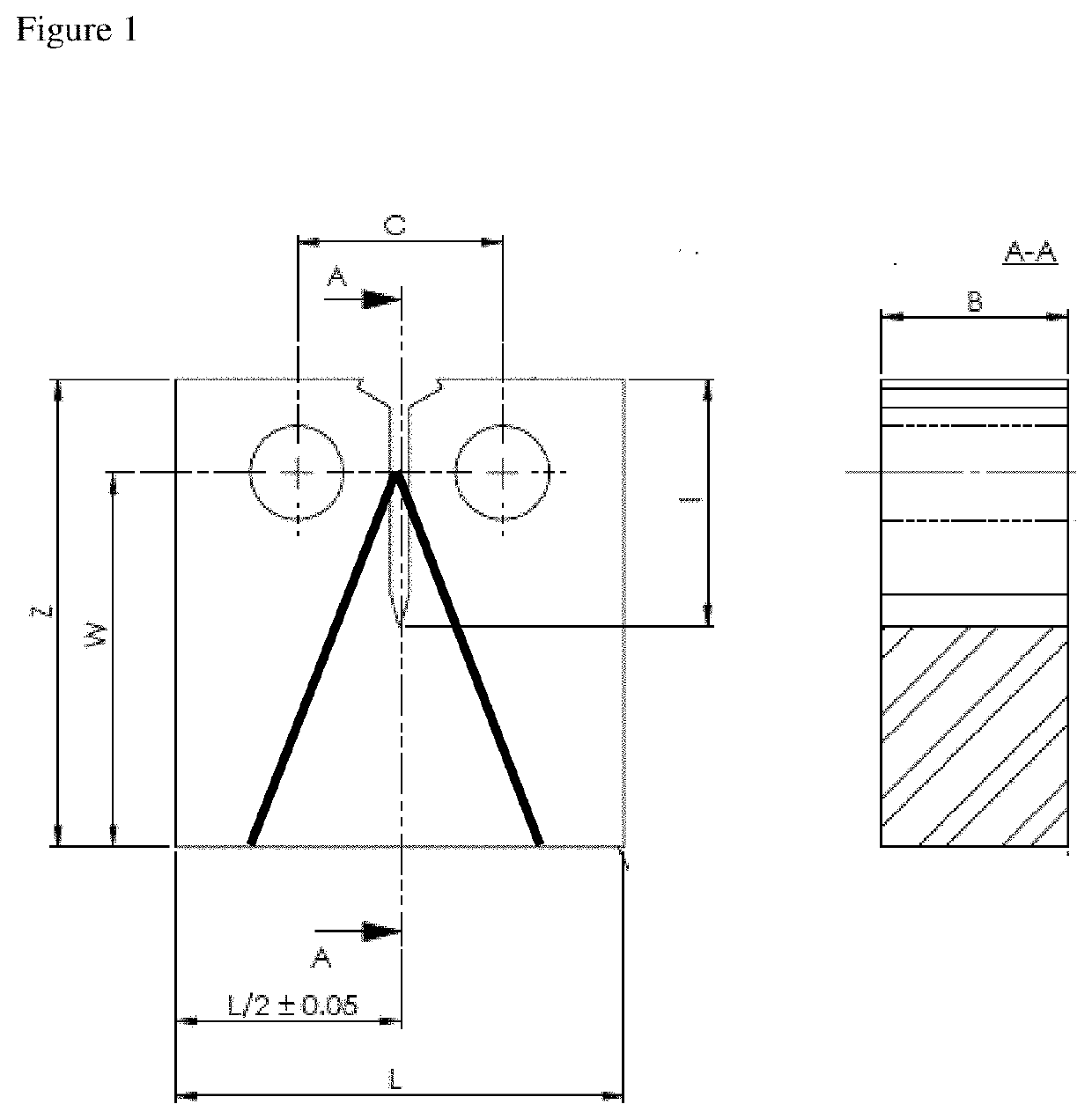

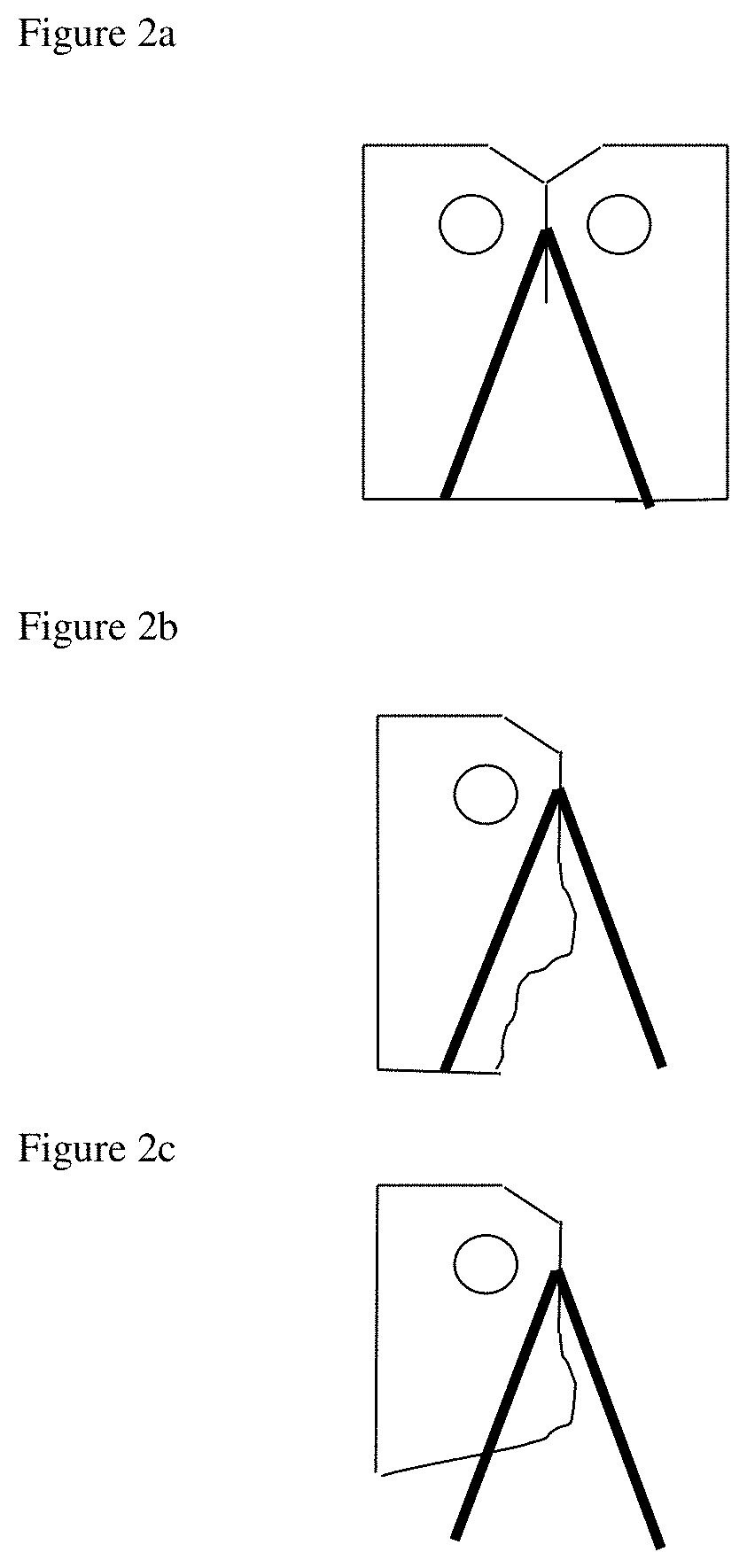

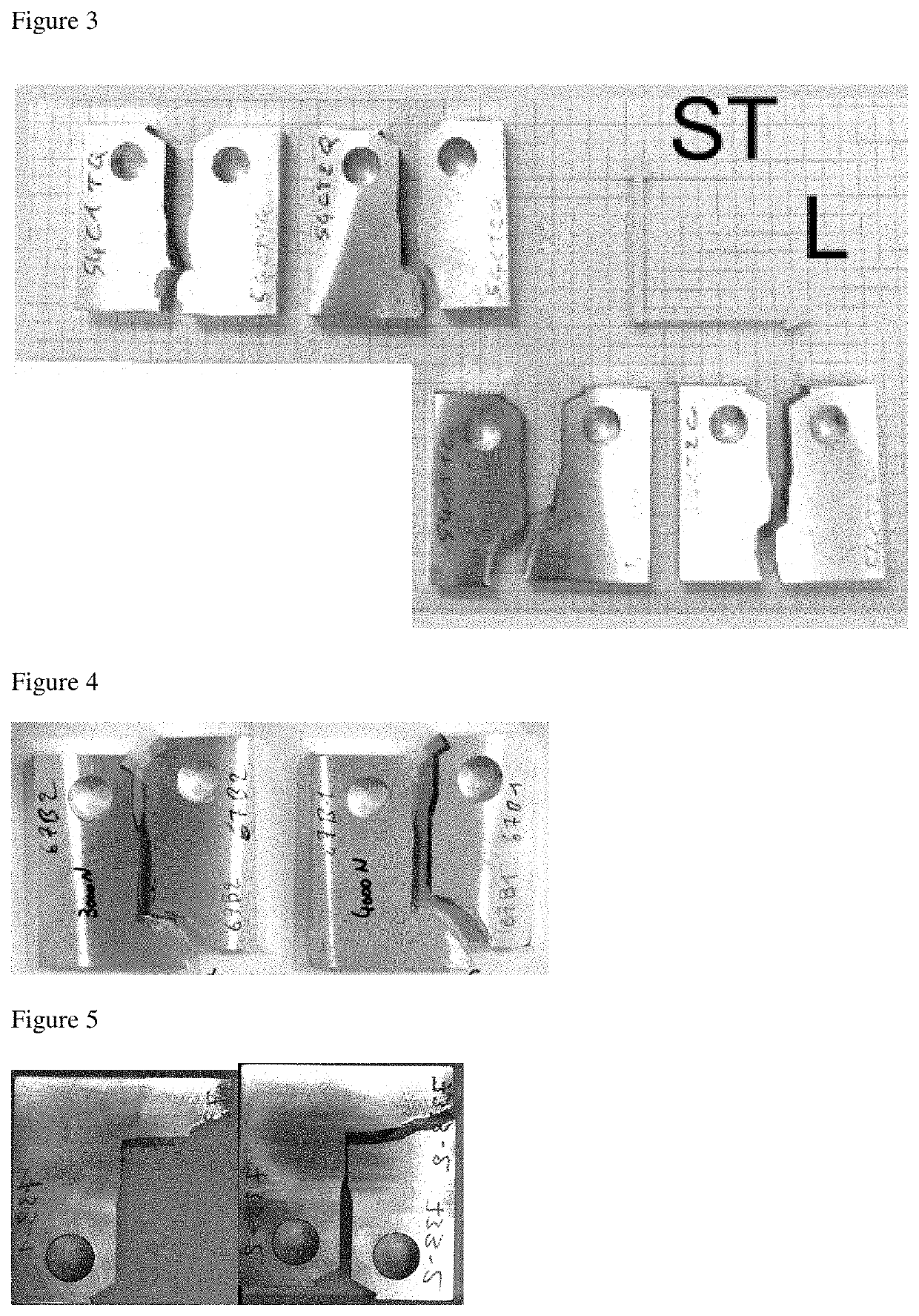

[0098]The L-S fatigue crack growth rate was measured according to standard ASTM E647 at mid-thickness and quarter thickness in the L-S direction on CT specimen (CT10W40 thickness 10 mm, width 40 mm) under a maximum load of 4 KN and R=0.1. The results are presented in Table 7.

TABLE 7Results of the L-S f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| da/dN | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com